No-capsulation cement packing bag

A packaging bag and cement technology, which is applied in the field of cement packaging bags, can solve the problems of cement being damp and solidified, aging, and polluting the environment, and achieve the effect of not being damp and suitable for long-distance transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

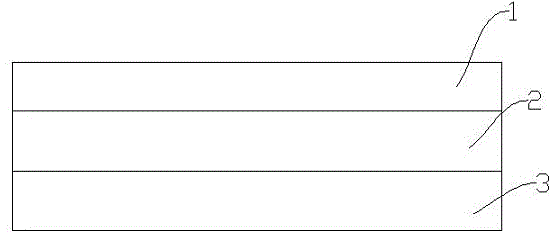

[0011] Such as figure 1 As shown, the present embodiment comprises inner layer 1, outer layer 3 and interlayer 2, inner layer 1 is glutinous rice paper, outer layer 3 is kraft paper, interlayer 2 is polypropylene or polyethylene laminating plastic woven bag, interlayer 2 and outer layer 3. Composite layer is formed by hot pressing, the inner layer 1 is an independent layer, and the composite layer is provided with a tear opening, and the tear opening is far away from the inner layer 1.

[0012] When opening the packaging bag, only need to open the tear opening from the composite layer, because the inner layer 1 is packaged with glutinous rice paper, and can be directly processed without opening the inner layer 1 in production.

[0013] The glutinous rice paper absorbs moisture, the outer layer 3 of kraft paper is moisture-proof and leak-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com