Turning belt conveyor

A technology of belt conveyors and belt conveyors, which is applied in the direction of conveyor objects, transportation and packaging, loading/unloading, etc., can solve the problems of inflexible movement of turning conveyor loading and unloading machines, cargo jamming or falling, troublesome operation, etc., to achieve The effect of smooth and safe cargo transportation, simplified structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

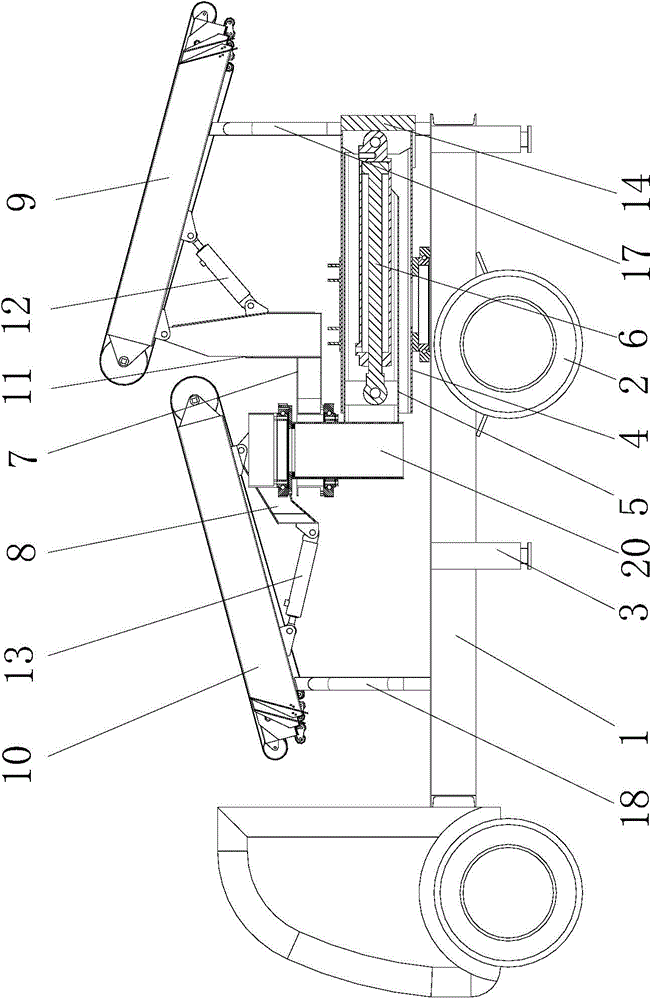

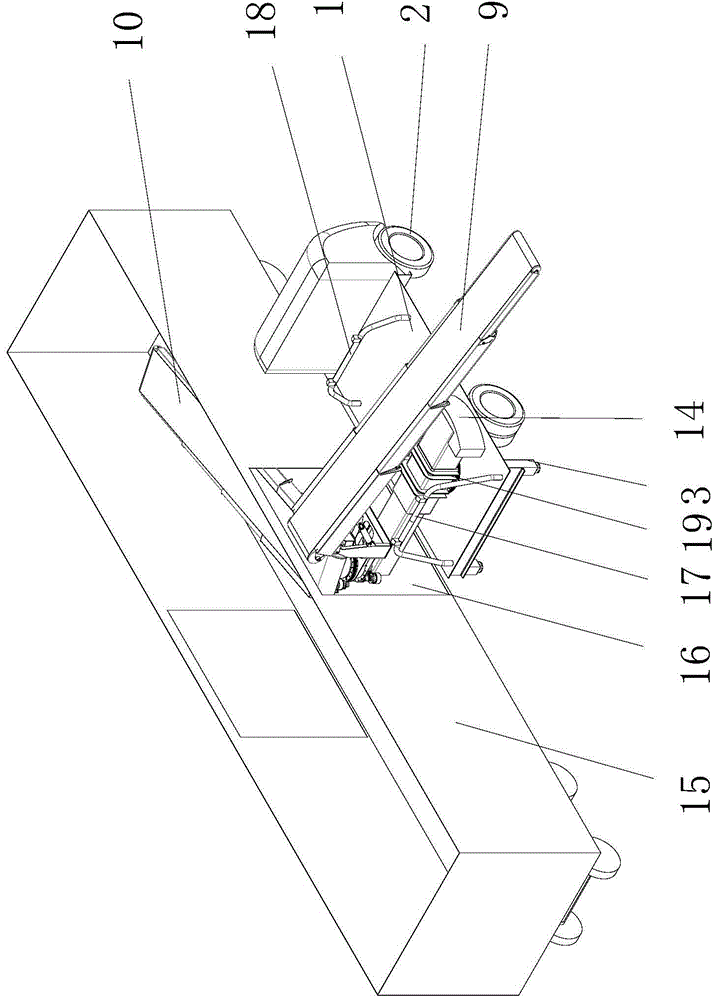

[0021] Such as figure 1 As shown, the curved belt conveyor of the present invention includes: a base, a chassis turntable 19, a lower turntable, an upper turntable, a belt conveyor and an electric control system; the base includes a chassis 1, wheels 2 and lifting legs 3 ;

[0022] The chassis turntable 19 and the chassis 1 are connected through a slewing bearing; a telescopic arm is installed on the chassis turntable 19, and the telescopic arm is composed of a square outer sleeve 4, a square inner sleeve 5 and a first hydraulic cylinder 6 Composition, the square outer sleeve 4 is set outside the square inner sleeve 5, the square outer sleeve 4 and the square inner sleeve 5 are in a sliding fit, and the first hydraulic cylinder 6 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com