Cathode electrolytic cell of device for preparing metallic sodium by electrolysis

A cathodic electrolysis and metal sodium technology, which is applied in the direction of electrolysis components, electrolysis process, diaphragm, etc., can solve the problems of difficult sealing, high sealing technology requirements, and difficult disassembly of the device, so as to achieve easy disassembly, improve safety performance, and airtight good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

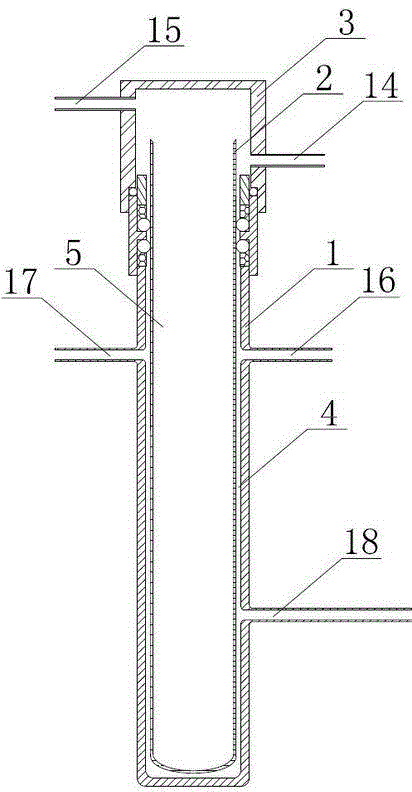

[0035] A cathodic electrolytic cell of a device for preparing sodium metal by electrolysis, comprising an electrolytic cell main body 1, Na-β-Al 2 o 3 Diaphragm tube 2, top cover 3 and sealing structure, the Na-β-Al 2 o 3 The diaphragm tube 2 is open at the top and closed at the bottom, and is arranged inside the electrolytic cell main body 1, the top cover 3 is arranged above the electrolytic cell main body 1, and the Na-β-Al 2 o 3 The top of the diaphragm tube 2 extends into the inside of the top cover 3, the sealing structure connects the top cover 3 with the electrolytic cell main body 1, and the sealing structure connects the Na-β-Al 2 o 3 The diaphragm tube 2 is fixed, and the Na-β-Al 2 o 3 A closed cavity is formed between the outer wall of the diaphragm tube 2 and the inner wall of the electrolytic cell main body 1, and the cavity is the cathode chamber 4, and the Na-β-Al 2 o 3 The airtight cavity between the inside of the diaphragm tube 2 and the inside of the...

Embodiment 2

[0037] A cathodic electrolytic cell of a device for preparing sodium metal by electrolysis, comprising an electrolytic cell main body 1, Na-β-Al 2 o 3 Diaphragm tube 2, top cover 3 and sealing structure, the Na-β-Al 2 o 3 The diaphragm tube 2 is open at the top and closed at the bottom, and is arranged inside the electrolytic cell main body 1, the top cover 3 is arranged above the electrolytic cell main body 1, and the Na-β-Al 2 o 3 The top of the diaphragm tube 2 extends into the inside of the top cover 3, the sealing structure connects the top cover 3 with the electrolytic cell main body 1, and the sealing structure connects the Na-β-Al 2 o 3 The diaphragm tube 2 is fixed, and the Na-β-Al 2 o 3 A closed cavity is formed between the outer wall of the diaphragm tube 2 and the inner wall of the electrolytic cell main body 1, and the cavity is the cathode chamber 4, and the Na-β-Al 2 o 3 The airtight cavity between the inside of the diaphragm tube 2 and the inside of the...

Embodiment 3

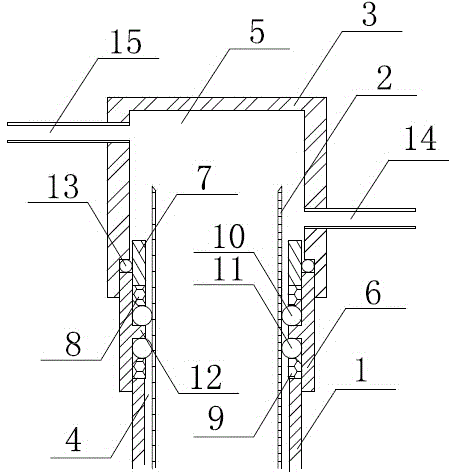

[0041] On the basis of embodiment 2:

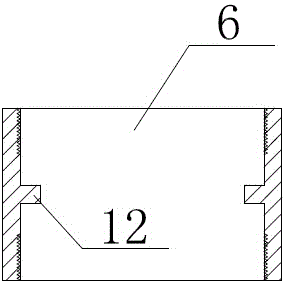

[0042] The upper and lower parts of the inner wall of the fixing ring 6 are provided with internal threads, the middle part of the inner wall is provided with an annular protrusion 12, and the lower part of the outer wall of the fastening ring 7 is provided with external threads, and the external threads are connected to the fixed ring. The inner thread on the upper part of the inner wall of the ring 6 is connected, the upper part of the outer wall of the electrolytic cell main body 1 is provided with an outer thread, and the outer thread is connected with the inner thread on the lower part of the inner wall of the fixed ring 6; the upper pressure ring 8 is arranged on the between the fastening ring 7 and the upper edge of the annular protrusion 12, and press the upper sealing ring 10 on the upper edge of the annular protrusion 12 and the Na-β-Al 2 o 3 Between the outer walls of the diaphragm tube 2, the lower pressure ring 8 is arranged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com