Miniature vacuum valve for flywheel

A vacuum valve and miniature technology, which is applied in the direction of valve devices, engine components, mechanical equipment, etc., can solve the problems of complicated operation process, large space occupation, and aesthetic impact, and achieve the effects of small size, waste reduction, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

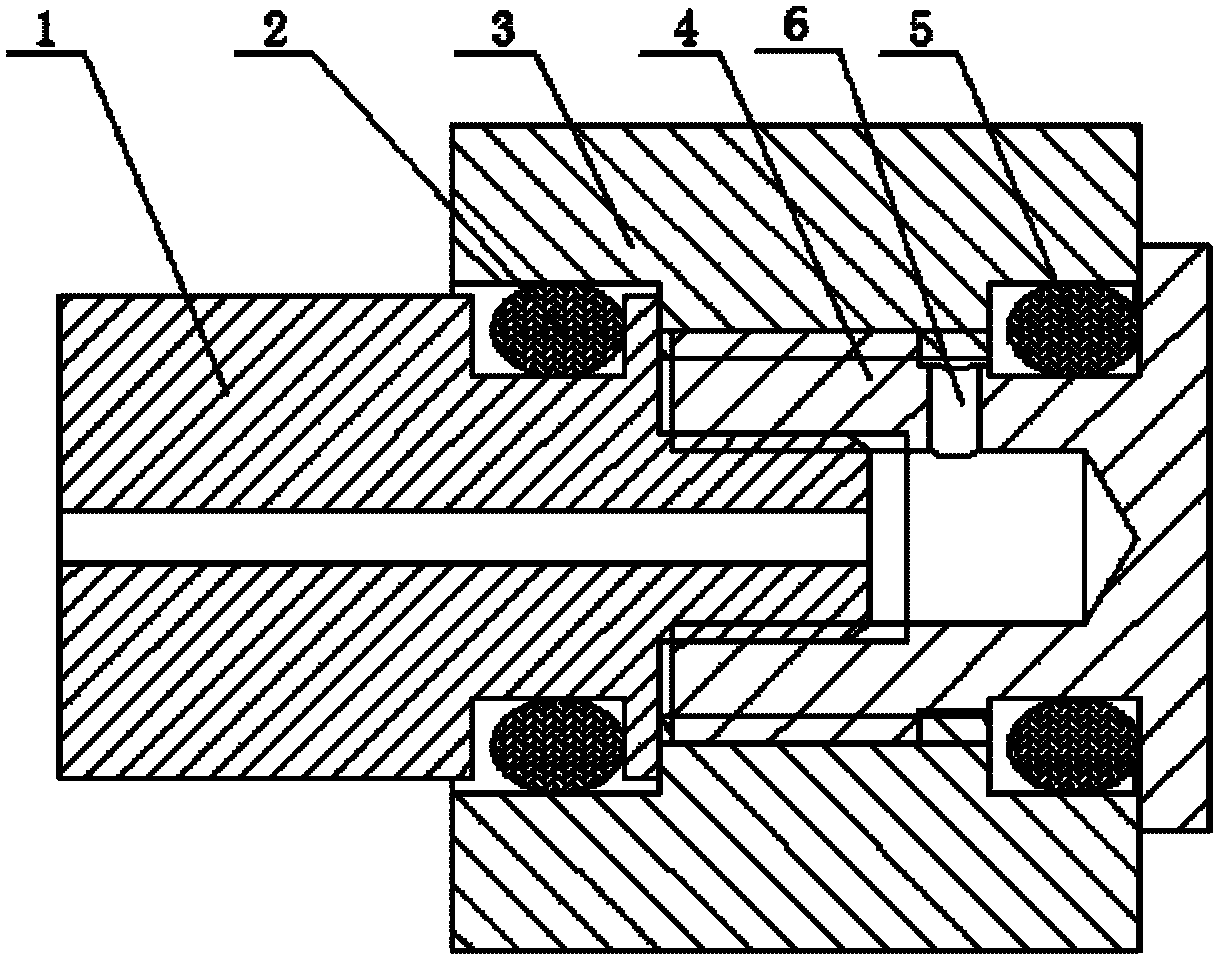

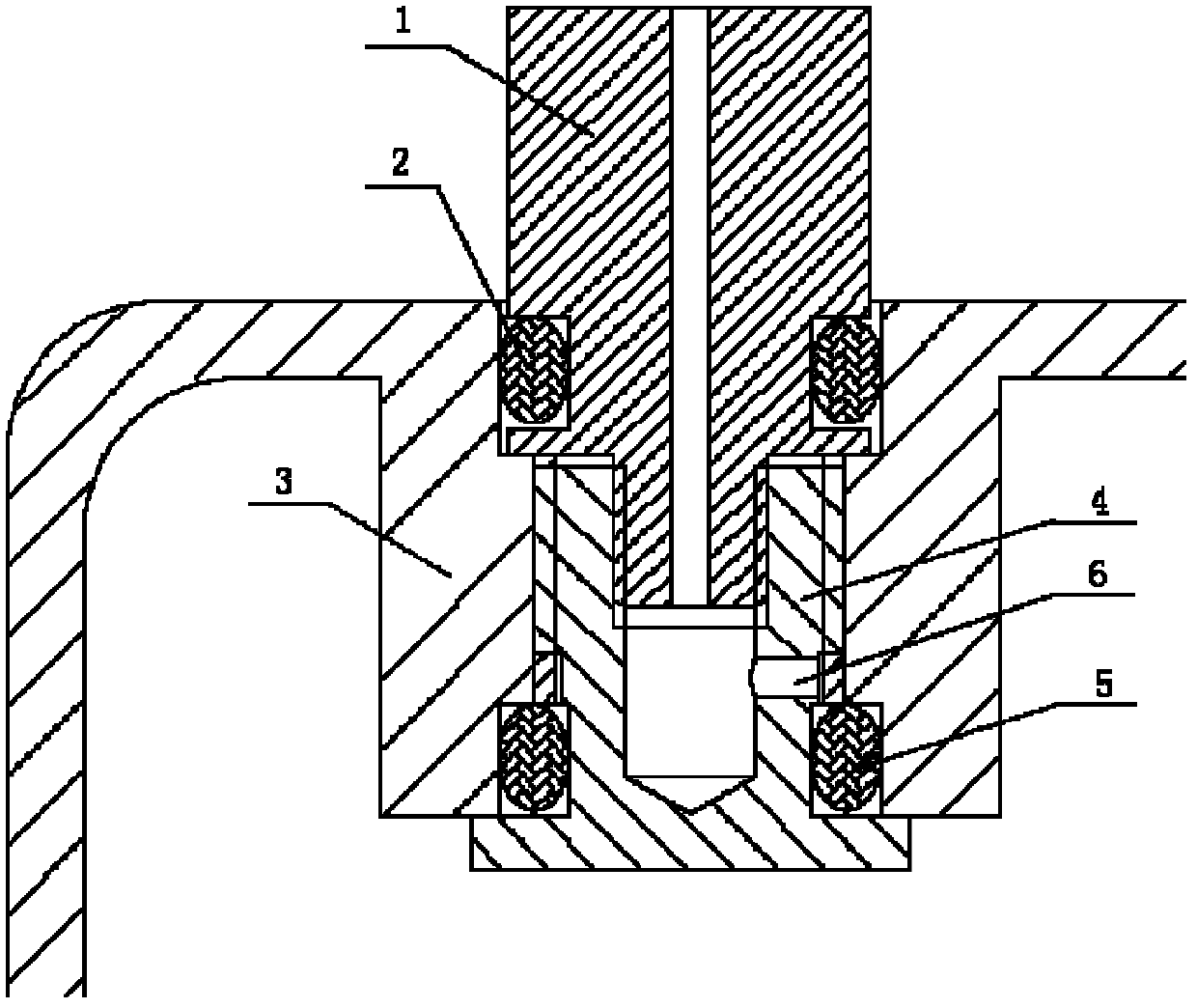

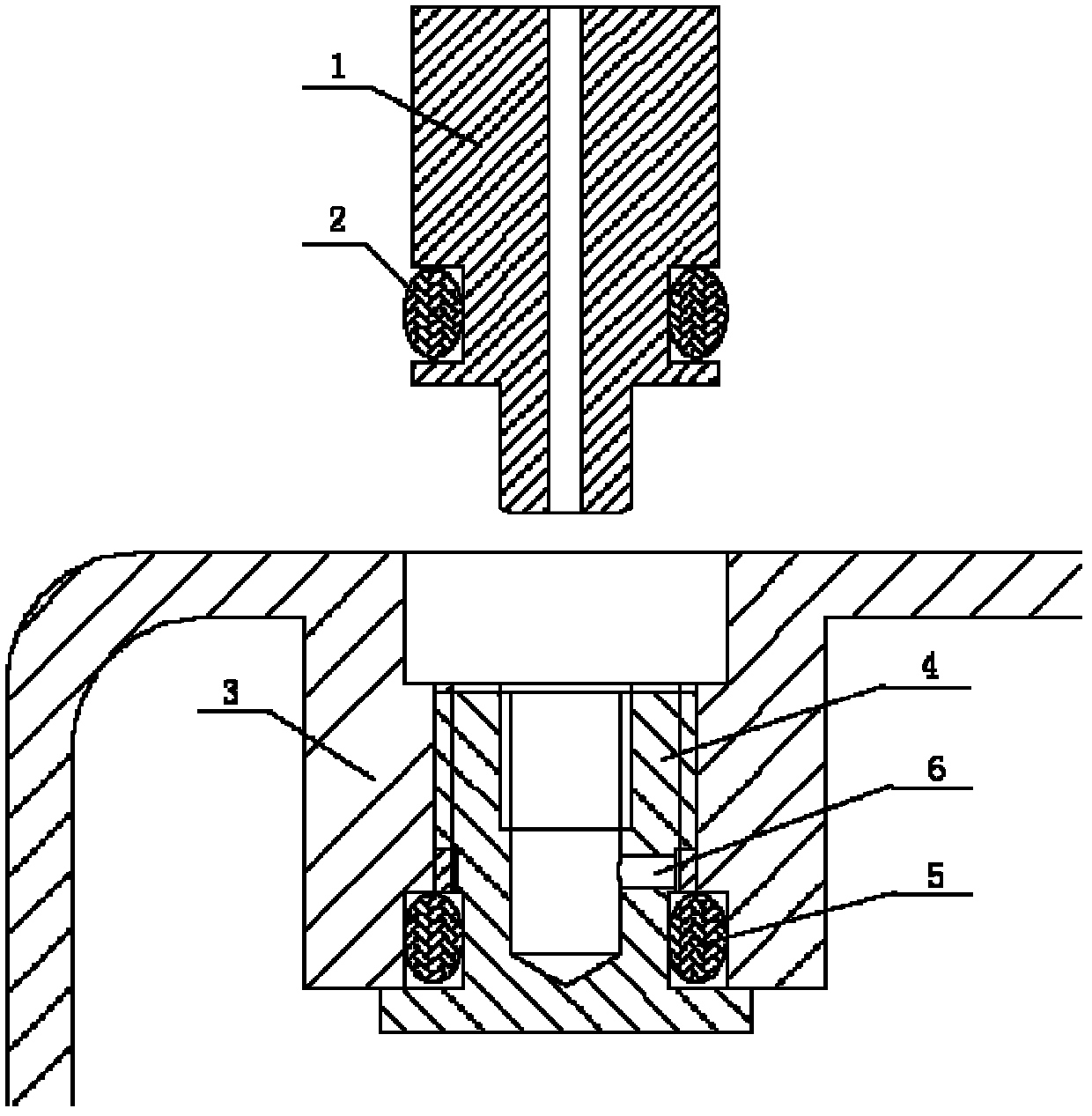

[0018] Such as Figure 1 to Figure 3 As shown, the miniature vacuum valve for flywheel of the present invention is mainly composed of an air extraction interface 1, a first O-ring 2, a valve body 3, a valve core 4, and a second O-ring 5. Among them, the valve body 3 is a part of the flywheel vacuum chamber, and the rotation of the vacuum chamber makes the valve body 3 rotate, the cooperation between the valve core 4 and the valve body 3, and the cooperation between the valve core 4 and the air extraction interface 1 are all threaded connections, and the valve core 4 is a double-thread structure, the outer thread and the inner thread have the same direction of rotation, pitch and lead, and the second O-ring 5 is used for sealing. The air extraction interface 1 is a piston structure, and the first O-ring 2 is used for seal.

[0019] Rotate the valve body 3 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com