Z-shaped sleeve constrained in-line pure steel buckling constrained support and manufacturing method thereof

A technology of buckling constraints and sleeves, which is applied in the direction of building components, earthquake resistance, etc., can solve the problems of complex assembly of core units and peripheral constraint sleeves, unfavorable standardized operations and large-scale production, and high processing and manufacturing costs, so as to facilitate standardized operations and large-scale production, improving steel utilization efficiency, and shortening the processing period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

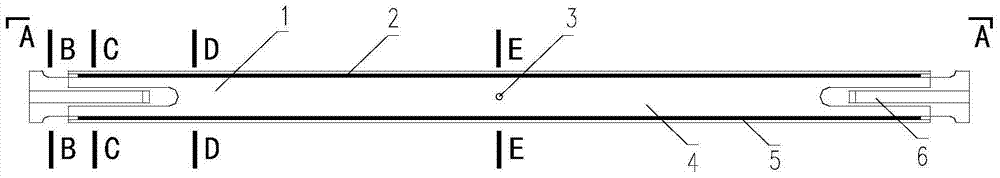

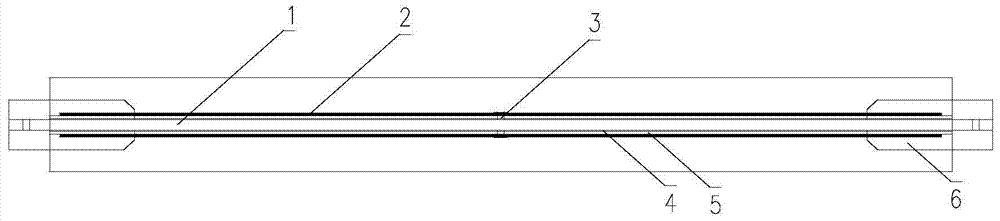

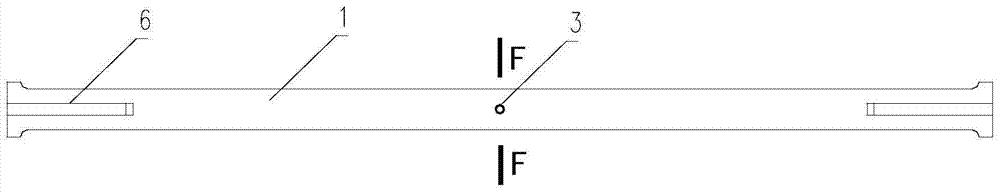

[0032] see Figure 1-8 , the Z-shaped sleeve constrains the in-line pure steel buckling restraint support, which is composed of in-line core steel plate 1, small-diameter round steel 2, large-diameter round steel 3, peripheral constraint sleeve 4, and unbonded structural layer 5 (because this layer is too Thin, can't be shown in the figure) and stiffening plate 6, wherein the specific structural shape of each component and the connection relationship between each other are as follows.

[0033] Figure 1-8 It shows an embodiment of the present invention and Z-shaped sleeve constrained in-line pure steel buckling restraint support, including a core plate 1 with an in-line cross section and a peripheral constraining sleeve 4 sleeved on the core plate 1, the peripheral On the upper and lower inner walls of the constraining sleeve 4, four small-diameter ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com