Binary plug type spray pipe having reverse thrusting function

A plug-type nozzle and function technology, which is applied in the field of binary plug-type nozzles, can solve the problems of complex structure of the thrust reverser and easy air leakage, and achieve the effects of light weight, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated.

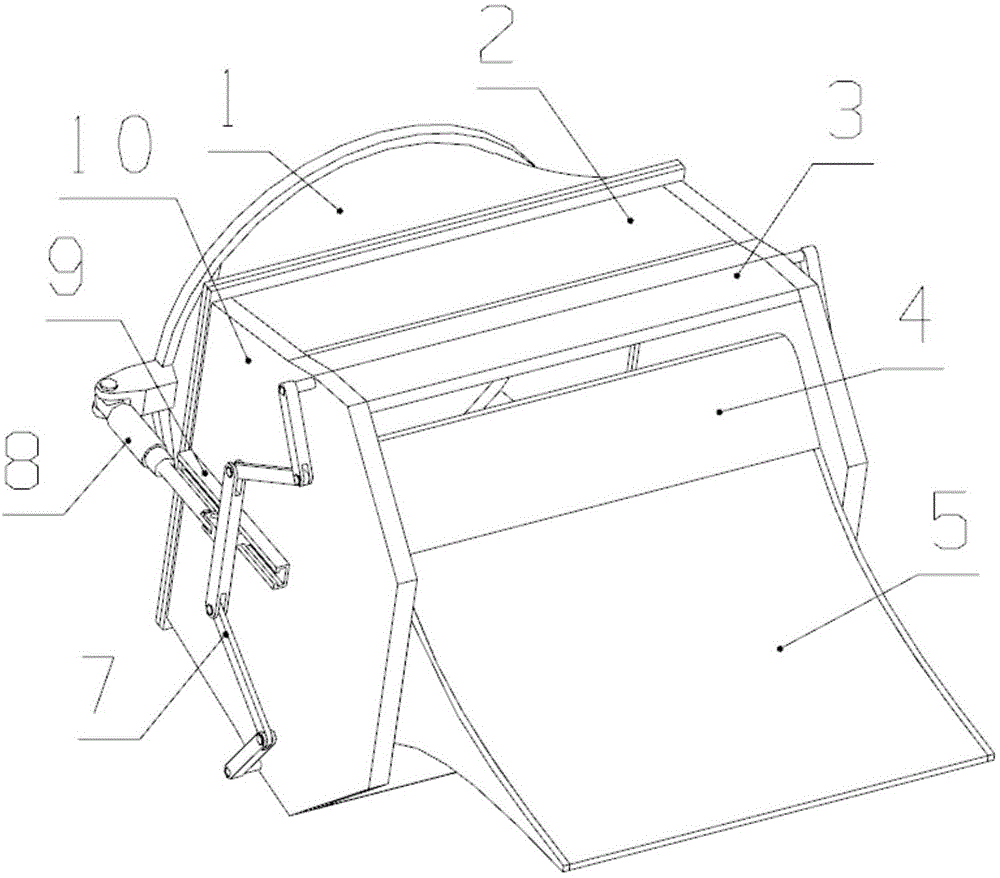

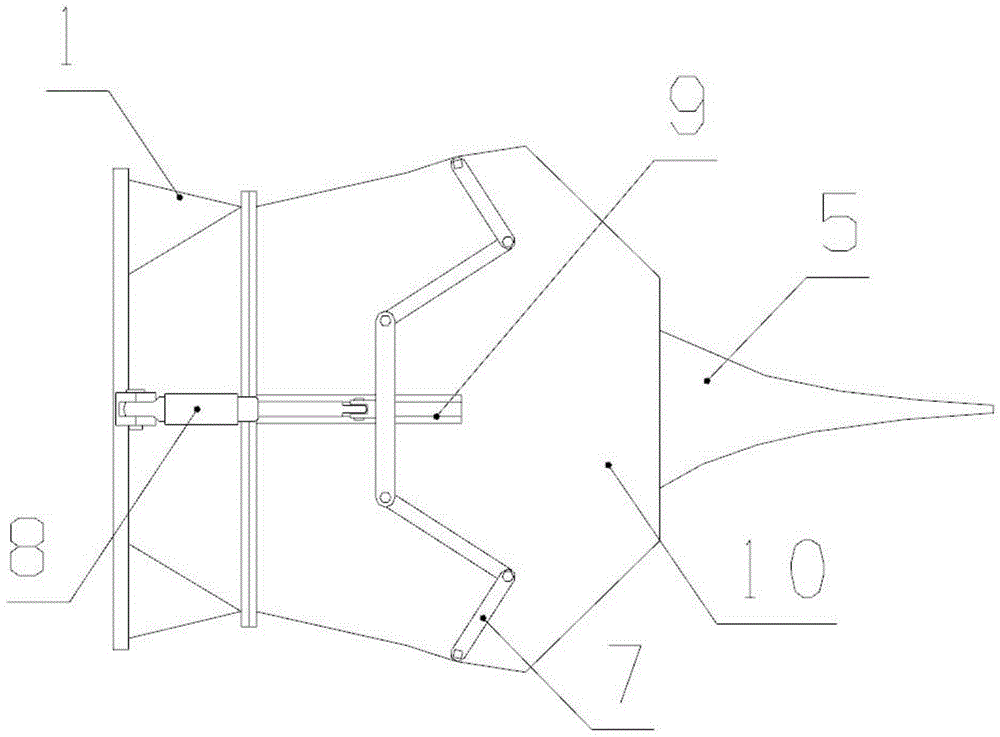

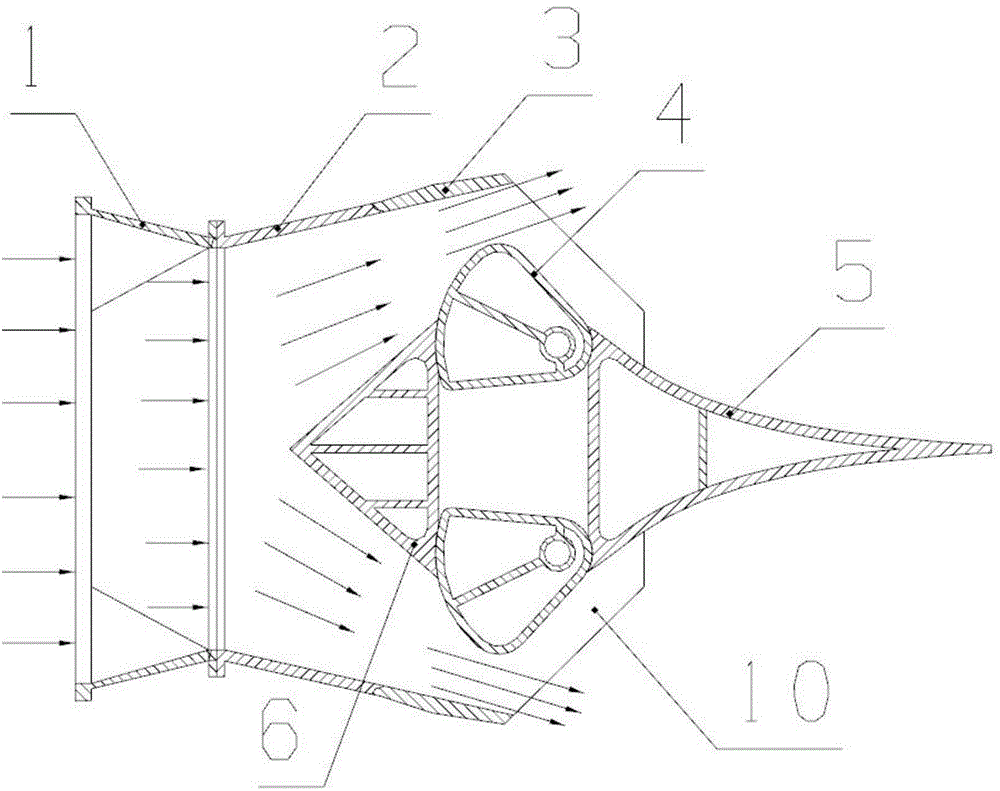

[0028] like Figure 1 to Figure 6 As shown, the binary plug nozzle with reverse thrust function of the present invention includes a rounded square cylinder 1 and a converging section.

[0029] Specifically, the round-rotating square cylinder body 1 is connected with the front-end engine as a supporting member for the entire nozzle. One end of the rounded square cylinder 1 away from the engine is fixedly connected with one end of the converging section. The convergent segment consists of two vertical blocks (according to figure 2 Viewing direction) and left and right symmetrically arranged side wall panels 10 and two converging plates symmetrically arranged up and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com