A radial shaft integrated flexible protective bearing for magnetic levitation high-speed rotating equipment

A flexible bearing protection, high-speed rotation technology, applied in sliding contact bearings and other directions, can solve the problems of mechanical damage to bearing cages, protect bearings from stuck and stop rotation, bearing expansion, etc., so as to reduce the probability of parts damage and improve service life. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

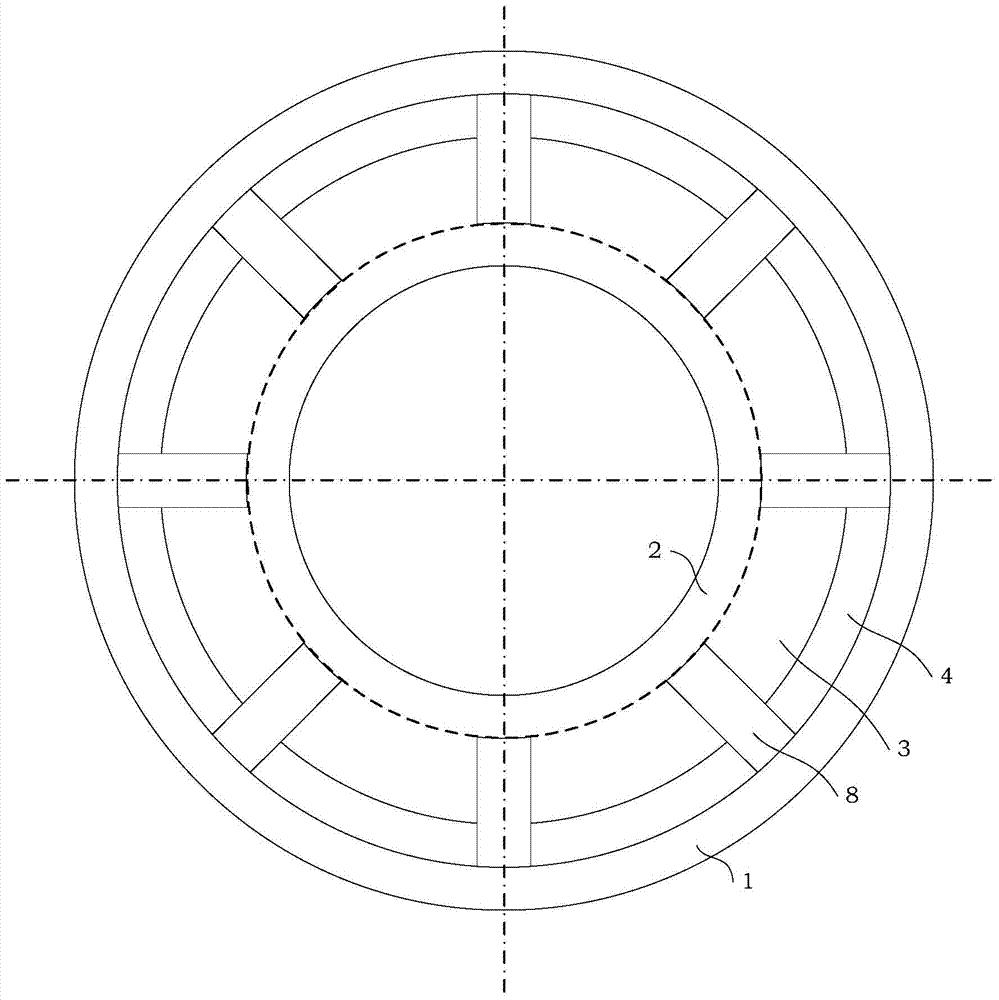

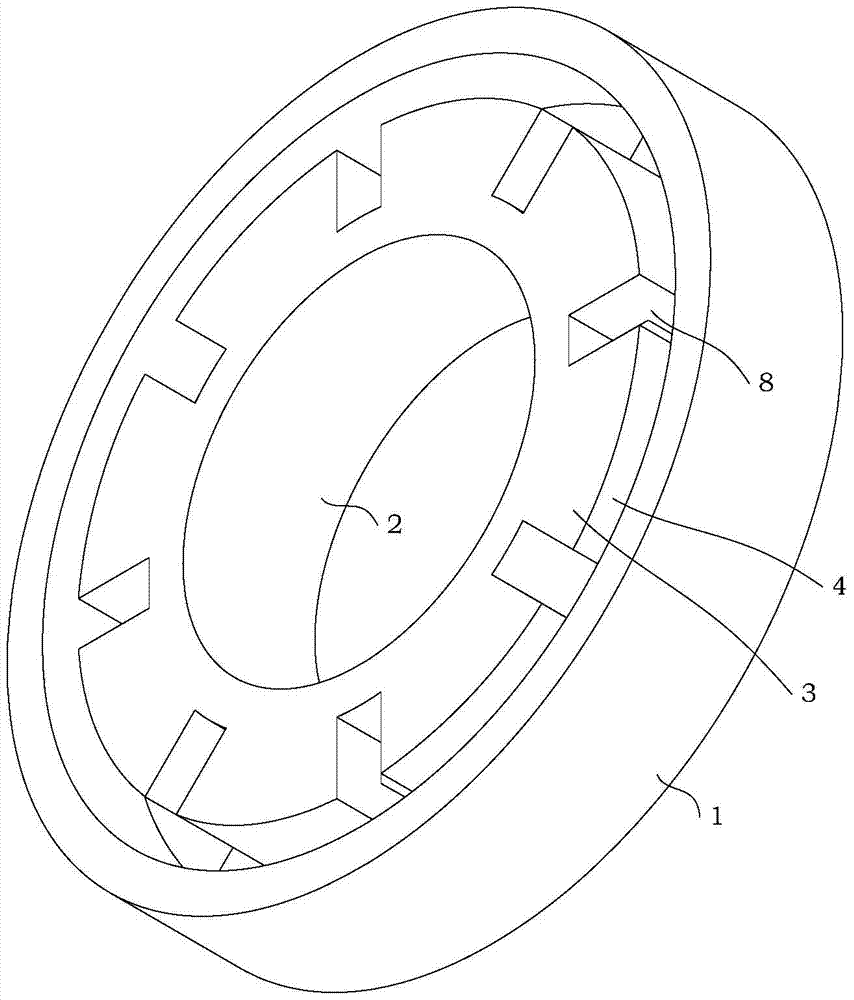

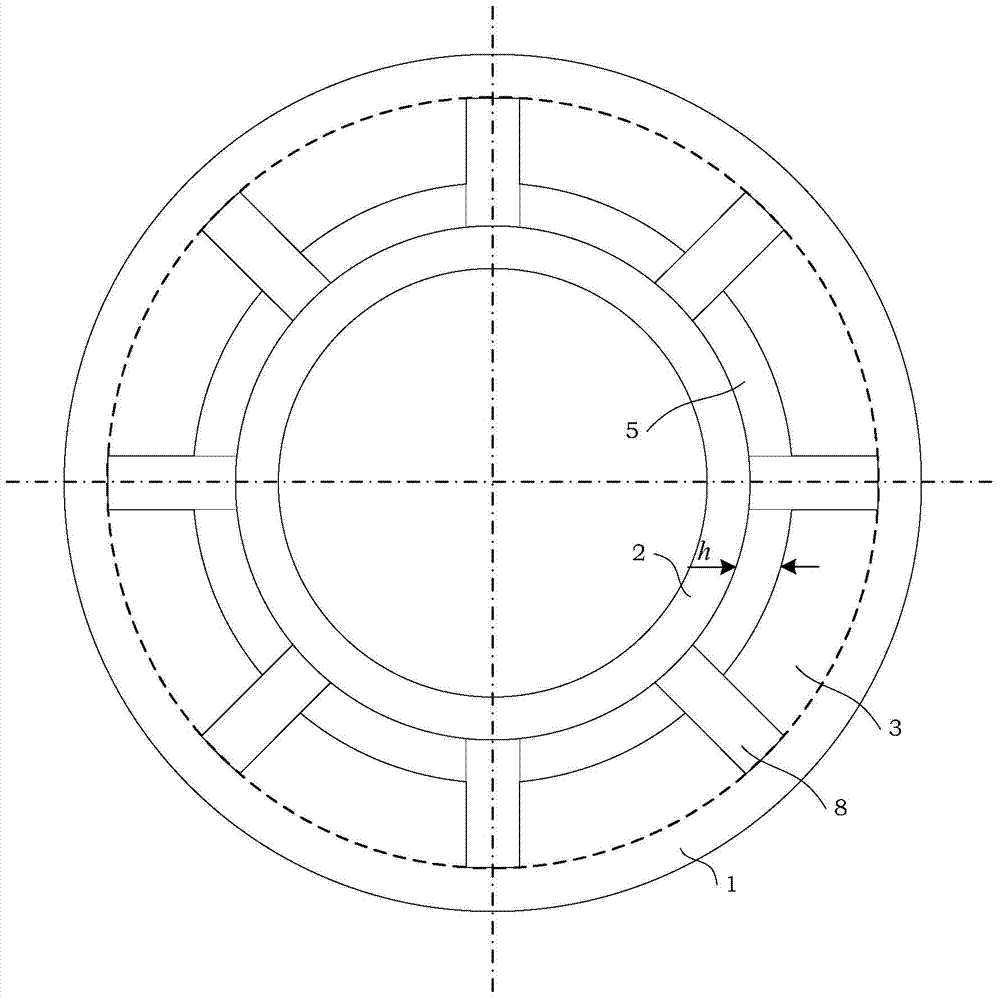

[0034] see figure 1 , Figure 1A , figure 2 , Figure 2A As shown, a radially loaded flexible protective bearing for magnetic levitation high-speed rotating equipment designed by the present invention, the protective bearing is integrally processed into a structural part; the protective bearing is designed with a bearing outer ring 1 and a bearing inner ring 2 , a Z-shaped structure 3 and a hollow groove 8; the Z-shaped structure 3 is placed between the bearing outer ring 1 and the bearing inner ring 2, and there is an outer annular recess between the Z-shaped structure 3 and the bearing outer ring 1 There is an inner annular groove 5 between the groove 4 and the Z-shaped structure 3 and the bearing inner ring 2 . The hollow grooves 8 are arranged at intervals between the bearing outer ring 1 and the bearing inner ring 2 .

[0035] see image 3 , Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com