Fiber bragg grating sensor based intelligent flange gasket

A fiber grating and flange gasket technology, which is applied in the field of intelligent flange gaskets, can solve the problems of insufficient gasket contact stress, inability to effectively monitor gasket sealing failure status, and reduction of gasket contact stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

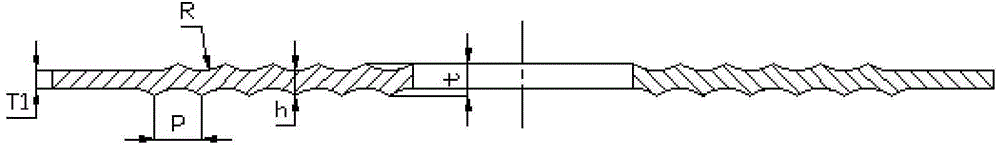

[0035] The intelligent flange gasket based on fiber grating sensing provided by the present invention is based on the metal skeleton of the corrugated composite gasket, and the fiber grating strain sensor and the fiber grating temperature sensor are respectively laid on its surface. The temperature and strain data of the gasket can be used to timely monitor the sealing force drop that may occur during the service process of the gasket, so that measures can be taken as soon as possible to prevent the occurrence of leakage accidents.

[0036] The present invention will be further described below with reference to the embodiments and the accompanying drawings, but the present invention is not limited.

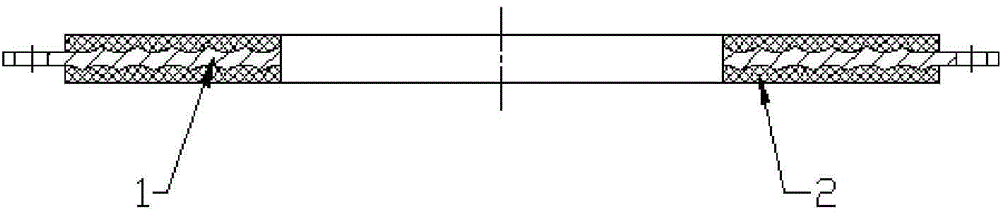

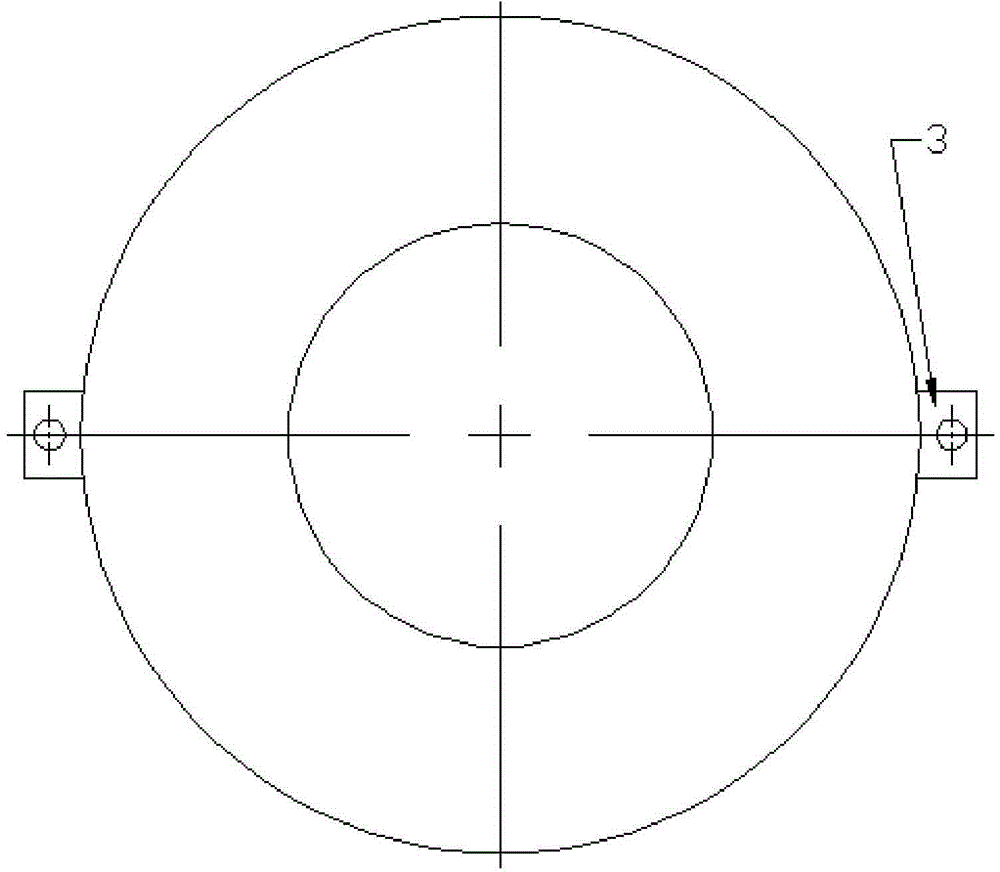

[0037] The intelligent flange gasket based on fiber grating sensing provided by the present invention has the following structure: Figure 1 to Figure 7 Shown: It consists of metal skeleton 1, surface composite material 2, radial fiber grating temperature sensor 4, circumferential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com