Sprayer nozzle used for tail jet flow interference test

A technology of tail nozzle and tail jet flow, which is applied in the direction of aerodynamic test, machine/structural component test, measuring device, etc. The problem of increasing the size of the boom can be solved, and the effect of meeting the requirements of the wind tunnel test, avoiding potential safety hazards, and reducing the degree of blockage can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further introduced below in conjunction with the accompanying drawings.

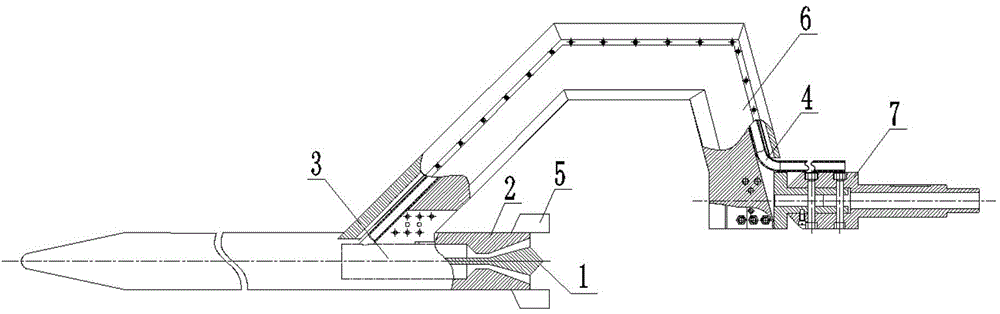

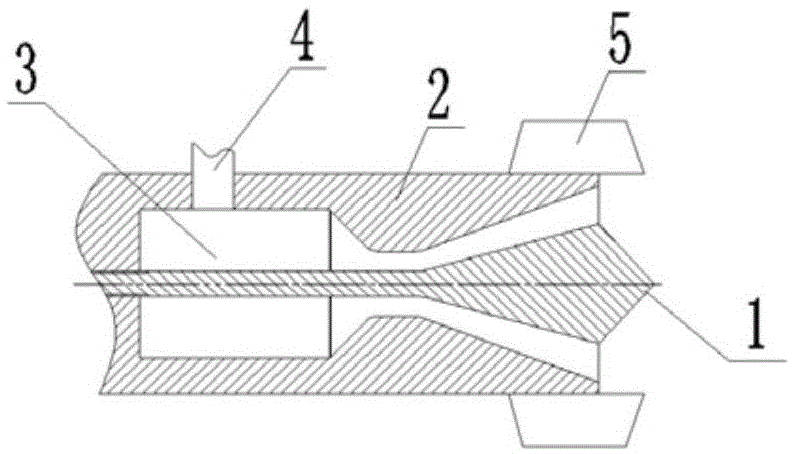

[0018] Such as figure 1 with figure 2 As shown, the experimental device used to simulate the flow disturbance at the bottom of the missile includes a central cone 1, a prototype tail nozzle 2, a plenum chamber 3, a high-pressure gas supply pipeline 4, a tail rudder 5, an arm 6, and a wind tunnel bracket Connector 7.

[0019] The plenum 3 is provided inside the missile model, the prototype tail nozzle 2 is connected with the plenum 3 , and the high-pressure air supply pipeline 4 is an adjustable small-diameter pipeline, which communicates with the plenum 3 .

[0020] Such as figure 2 As shown, the annular exhaust nozzle is formed by disposing the central cone 1 in the prototype exhaust nozzle 2 . In this embodiment, the central cone 1 includes a cone part, a cylinder part and a central connecting rod, the above-mentioned cone part is arranged in the expansion sec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap