Knob light guide structure

A technology of light guide structure and knob, applied in the field of vehicle, can solve the problems of limited structure, high space requirement, low utilization rate of light source, etc., and achieve the effect of high utilization efficiency of light source, reduction of transmission loss, and increase of visual effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

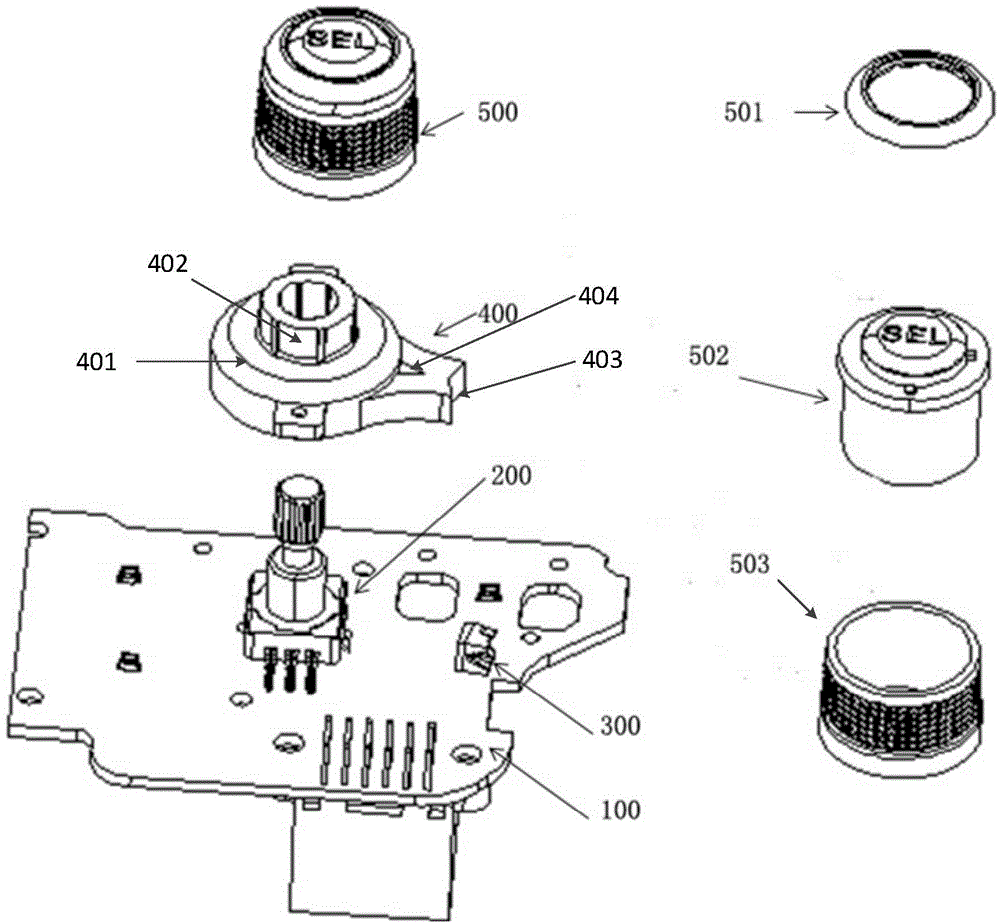

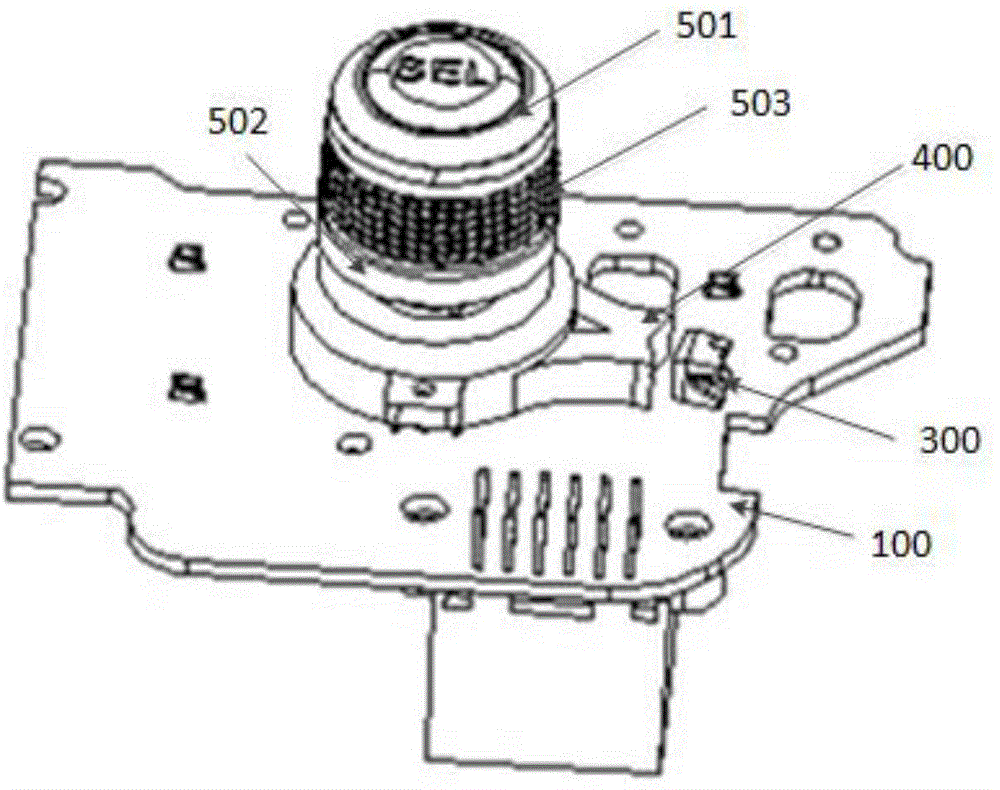

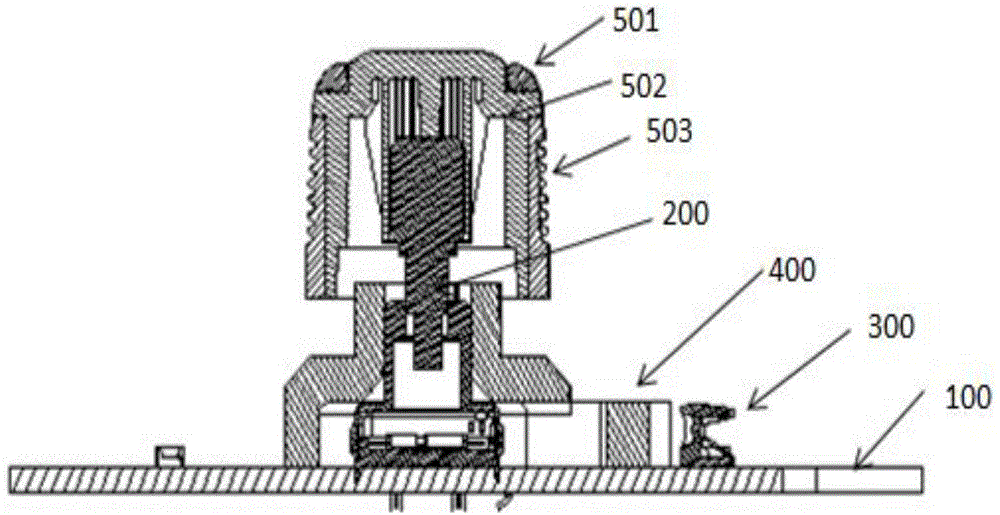

[0036] See attached figure 1 , is an exploded diagram of a knob light guiding structure in the present invention. A knob light guide structure, including a PCB board 100, at least one LED light source 300, an encoder 200 with a shaft handle and a shaft sleeve, a primary light guide ring 400 and a secondary light guide ring 502; the encoder 200 and the LED light source 300 are arranged on the PCB board 100, and the encoder 200 and the LED light source 300 can preferably be fixed on the PCB board 100 by welding; The fixing method is not limited.

[0037] The primary light guide ring is sleeved on the shaft sleeve of the encoder 200, and the light guide ring includes an elliptical light guide arm 401 and a light guide inner ring 402 with a certain angle chamfer. The angle of chamfering is preferably 45 degrees, and of course it can also be other angles. This embodiment does not limit the specific angle; and the edge of the light guide arm 401 is provided with a groove 403, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com