Spliced display screen

A splicing display and screen technology, applied in optics, instruments, projection devices, etc., can solve problems such as complex processing and assembly, glass falling and hurting people, mechanical splicing seams, etc., to achieve small pin connection gaps, reduce production costs, right-angled The effect of connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

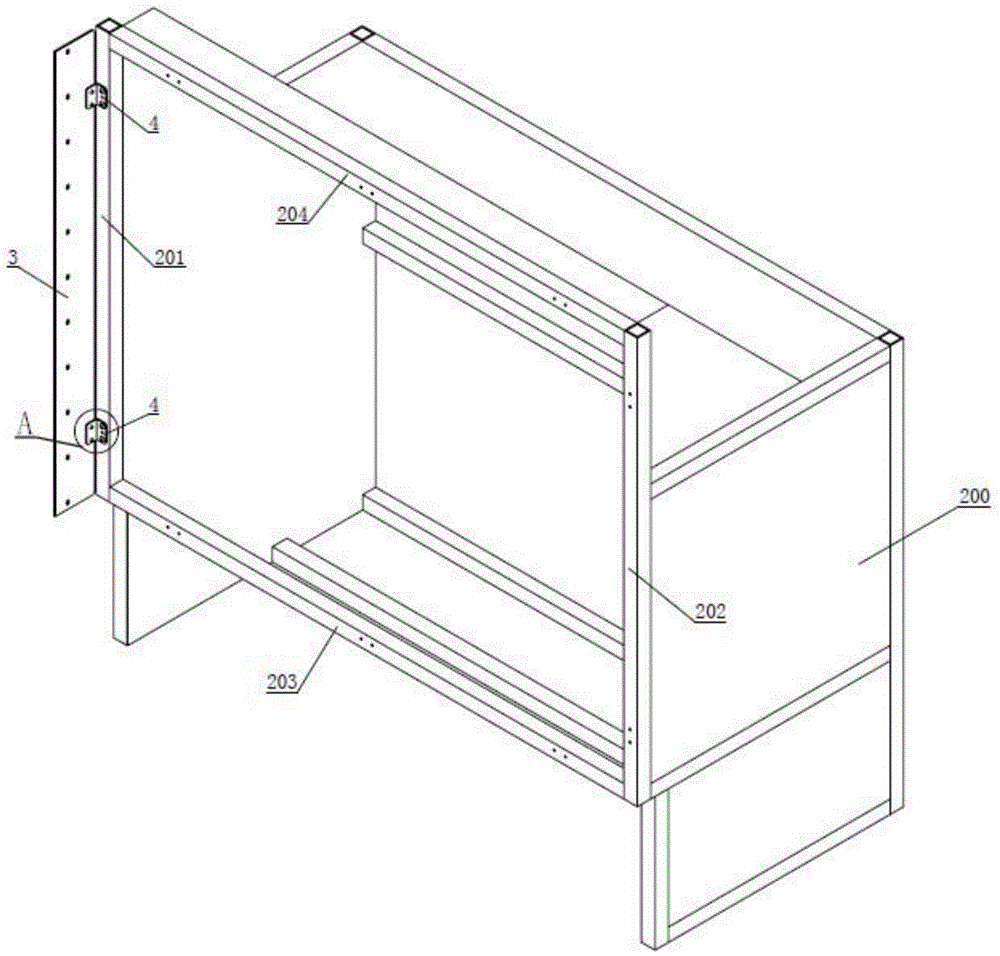

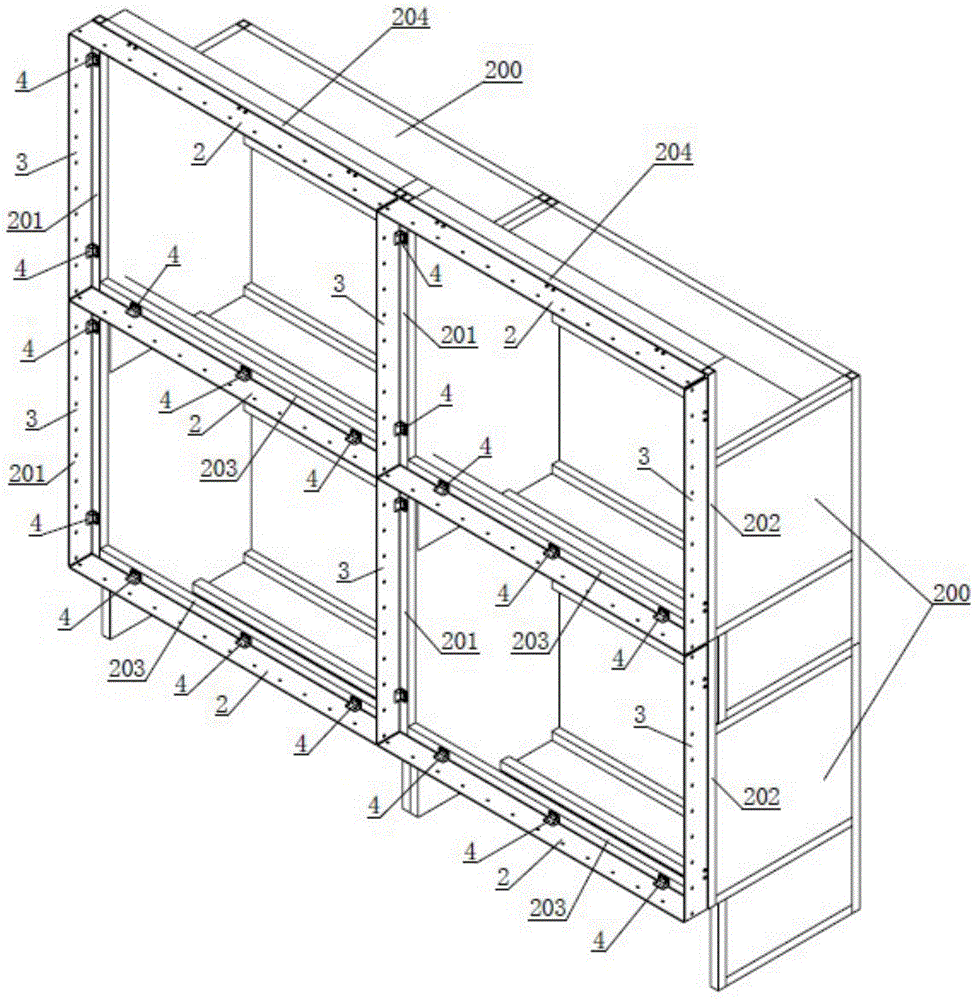

[0042] In order to achieve the purpose of the present invention, as Figure 1~4 As shown, in one embodiment of a stitched display screen of the present invention, the stitched display screen is formed by splicing 2×2 display components, and each display component includes: a screen 1, a splicing frame and a projection box 200; the projection box 200 has a rectangular installation frame that is easy to install; the splicing frame includes 2 upper and lower splicing plates 2 and 2 left and right splicing plates 3, the upper and lower splicing plates 2 have the same length as the upper and lower brackets of the installation frame, and the left and right splicing plates 3 are the same as the installation frame The left and right brackets have the same length;

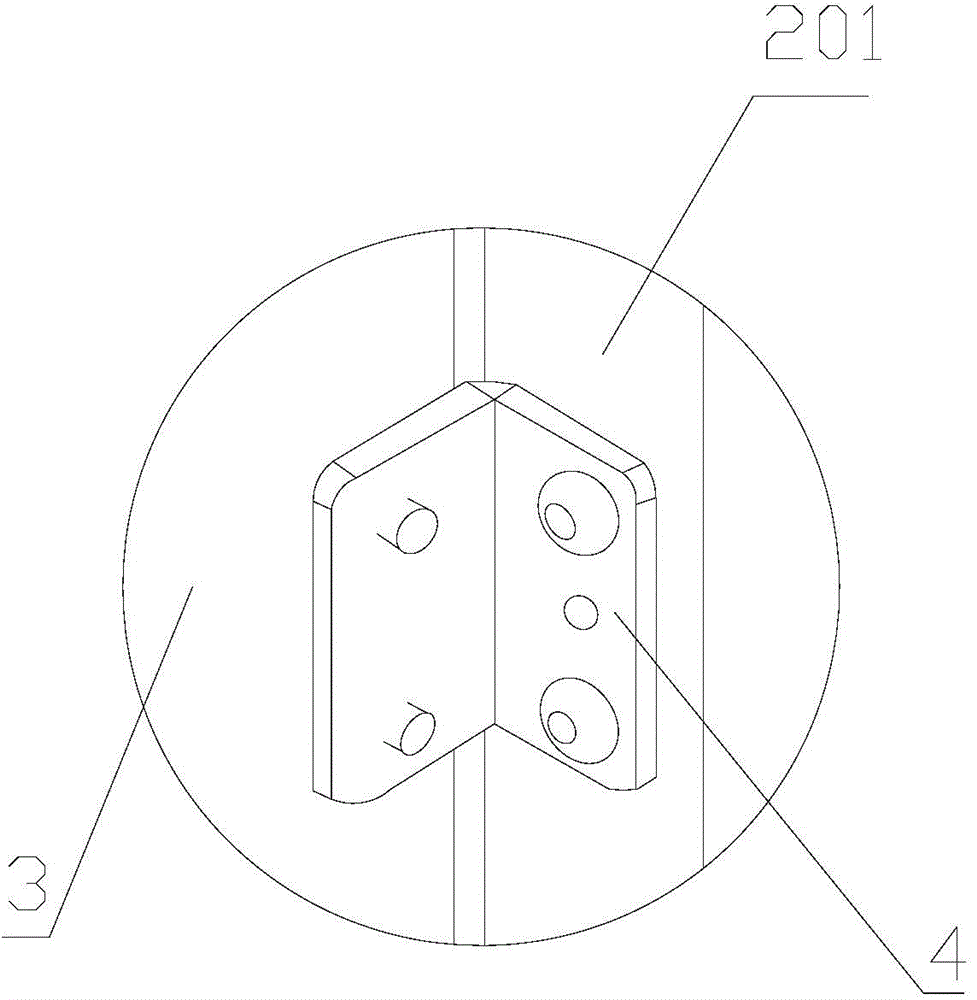

[0043] One side of the splicing plate is fixedly connected vertically at 90° to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com