Blender blade assembly and blender

A mixer and mixer tank technology, applied in chemical instruments and methods, mixers with rotary mixers, mixers, etc., to achieve improved mixing and mixing, optimized drag and lift, and superior mixing and the effect of mixing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

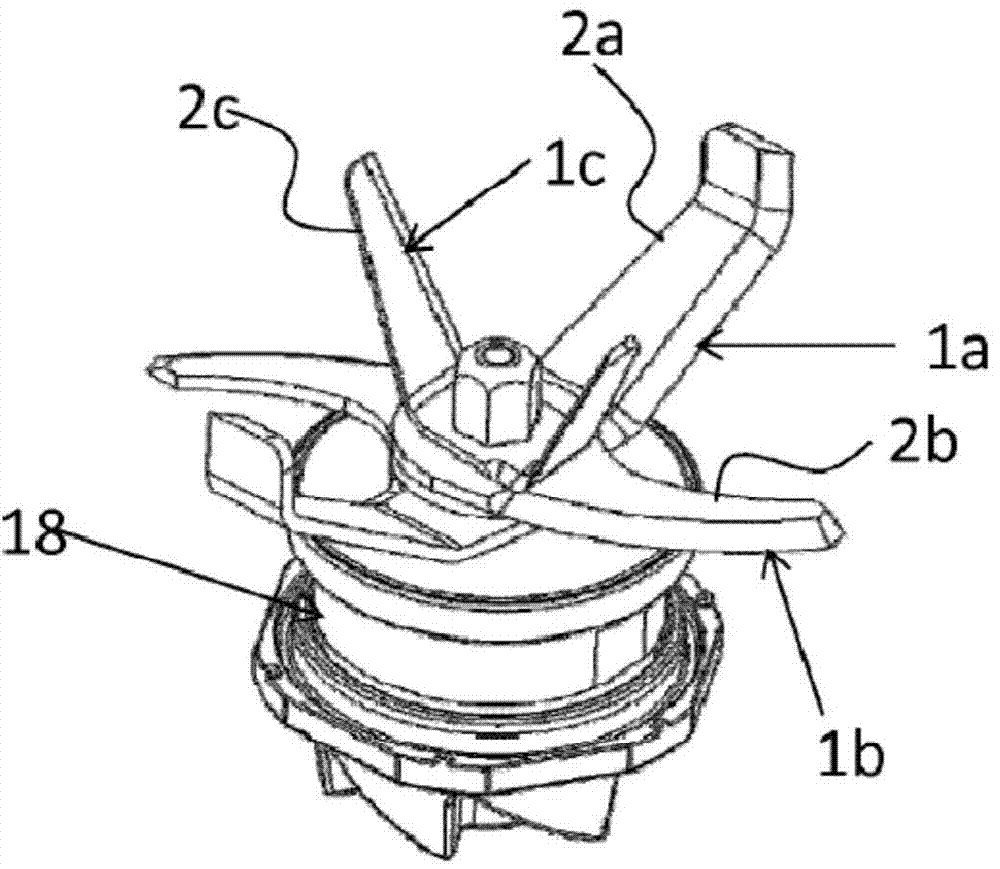

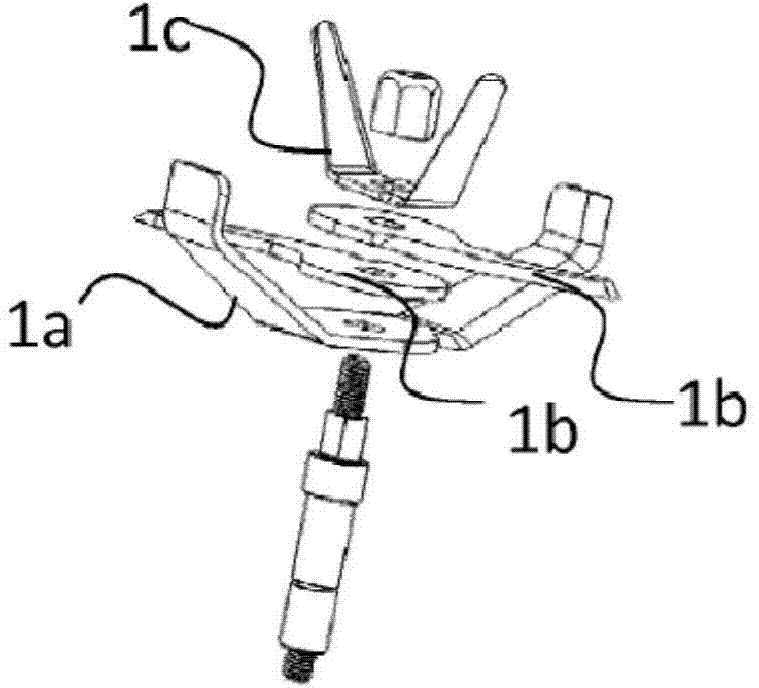

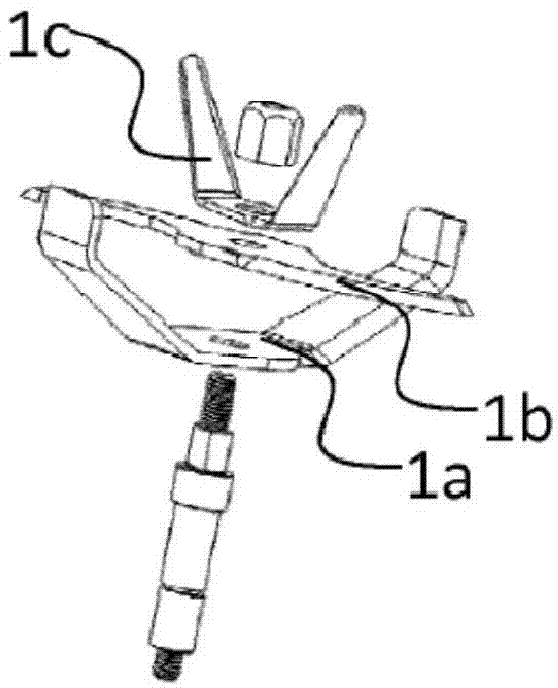

[0049] Figure 1a An embodiment of a blender blade assembly is shown. The vane assembly 18 includes a first vane 1a, referred to below Figure 3 to Figure 6 describe in detail. The first blade 1a has two symmetrical first blade arms 2a arranged for protruding outwards and upwards. The second blade 1b is arranged on top of the first blade 1a. The second blade is generally flat and has a curved profile (C-shape) on each second blade arm 2b. The C-shaped blades are tapered at the top. exist Figure 1b In the illustrated embodiment, the second blade 2a comprises two separate pieces or second blade arms 2b arranged on top of each other in the blade assembly, forming an S-shaped blade. In this way, a two-stage chopping or cutting area is produced. The second blade 1b can also be made of Figure 1c Manufactured from a single piece of material shown in . In the present embodiment, the second blade arms 2b are arranged opposite to each other on the same level. Typically, the C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com