Bus lamination self-cleaning handle

A bus and handle technology, which is applied to vehicle parts, special positions of vehicles, transportation and packaging, etc., can solve the problems that the handrails cannot be cleaned and disinfected, and hidden dangers to hygiene and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

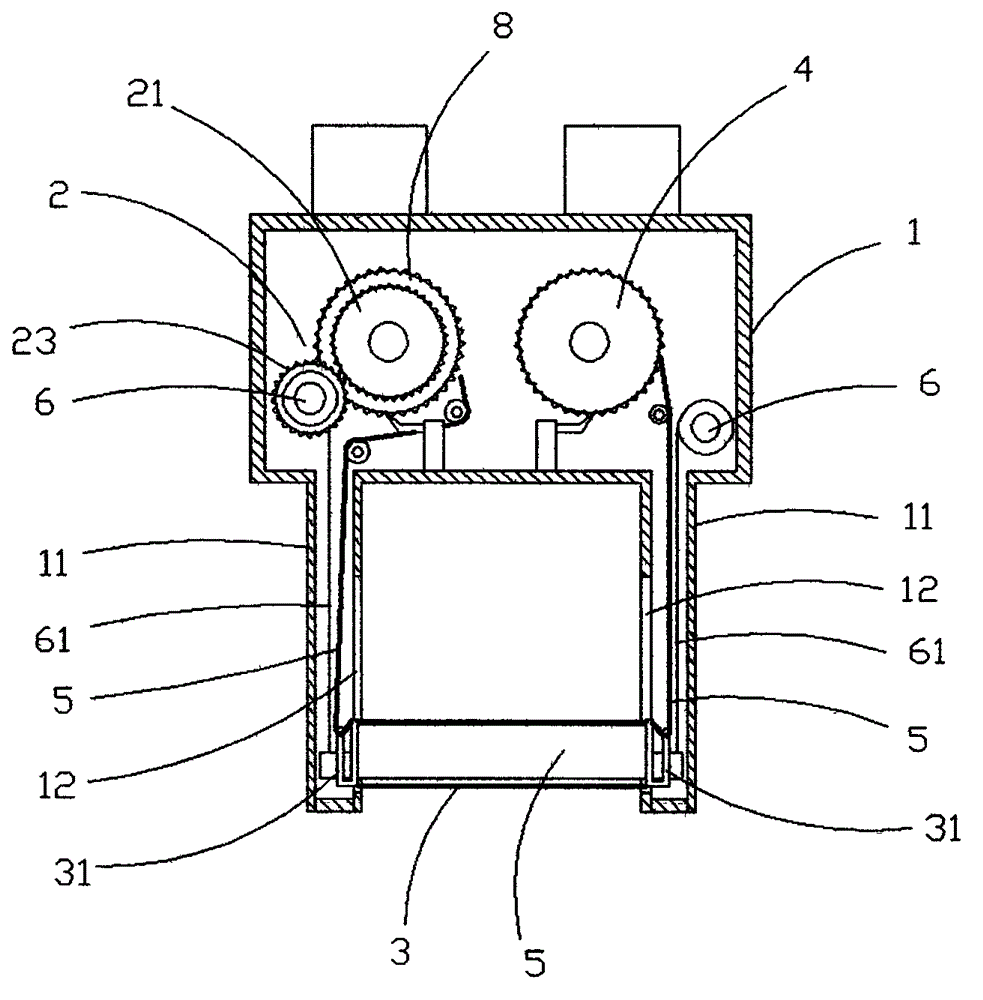

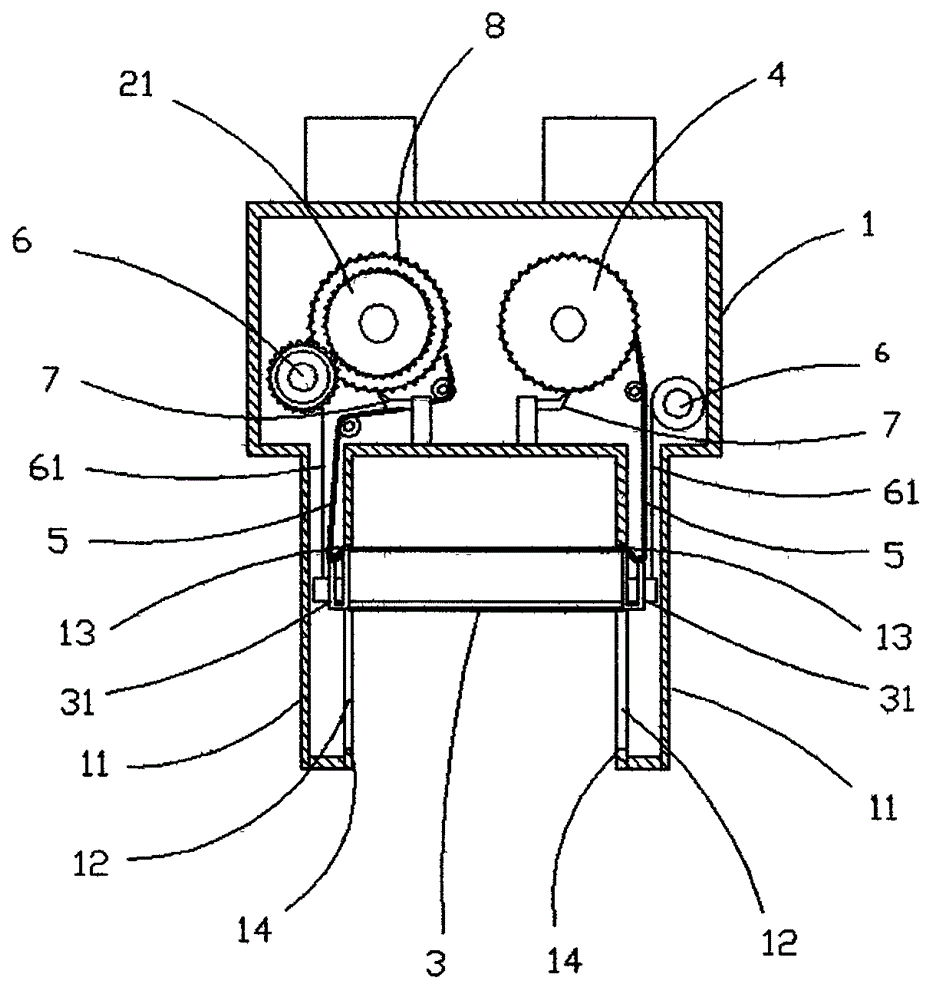

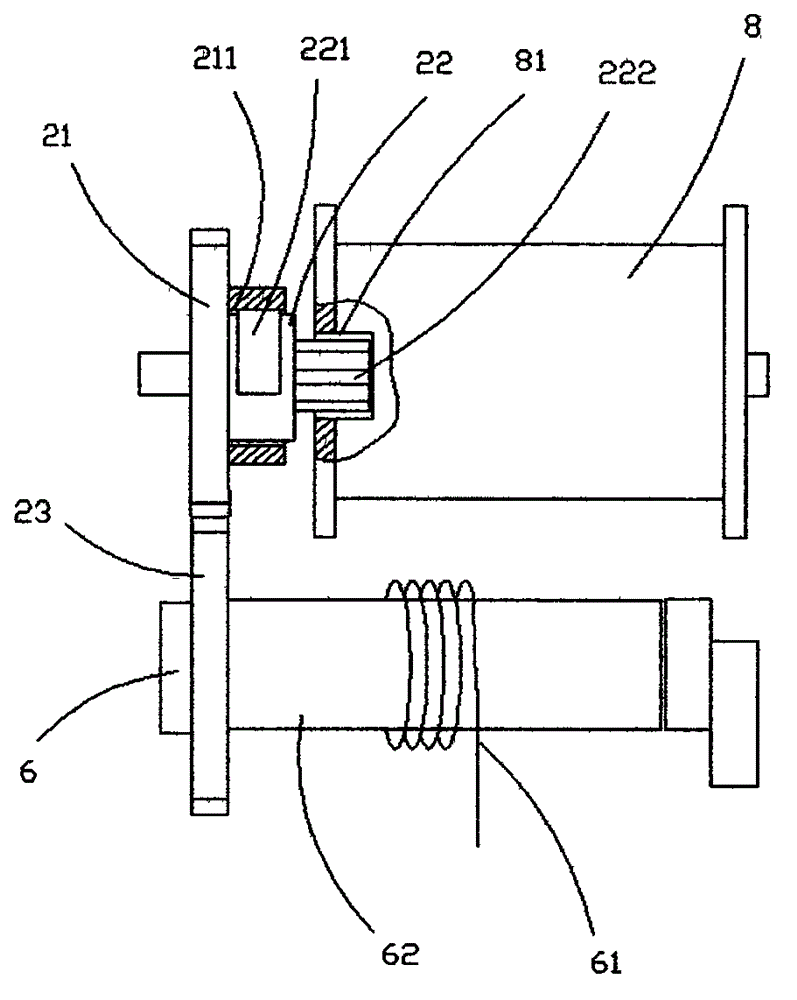

[0023] Such as figure 1 , 2 , shown in 3, a kind of bus compound film self-cleaning handle, this handle comprises outer casing 1, handle 3, compound film belt controller 2, reel, and the inner chamber of outer shell is provided with compound film belt controller 2, Laminated film belt controller 2 is made up of rotating mechanism 6, directional gear plate 21, and directional gear plate 21 is meshed with the gear 23 that links to each other with rotating mechanism, and the side of directional gear plate 21 is provided with tooth groove 211, is placed in this tooth groove 211 The curved claw 221 of the control part 22 cooperates with the ratchet 212, and the clamping column 222 on the control part 22 engages with the locking tooth 81 inserted in the shaft hole of the tape feed reel 8, and when the rotating mechanism 6 rotates, the tape feed reel is driven 8 for directional rotation, the longitudinal support arms 11 on both sides are cavity structures, the support arms 11 are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com