A self-cleaning range hood

An automatic cleaning and range hood technology, which is applied in the directions of removing oil fume, cleaning methods and utensils, and cleaning methods using tools, etc., can solve the problems of complex self-cleaning function structure, inconvenience, poor cleaning effect, etc. Value and market value, simple and novel structure, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

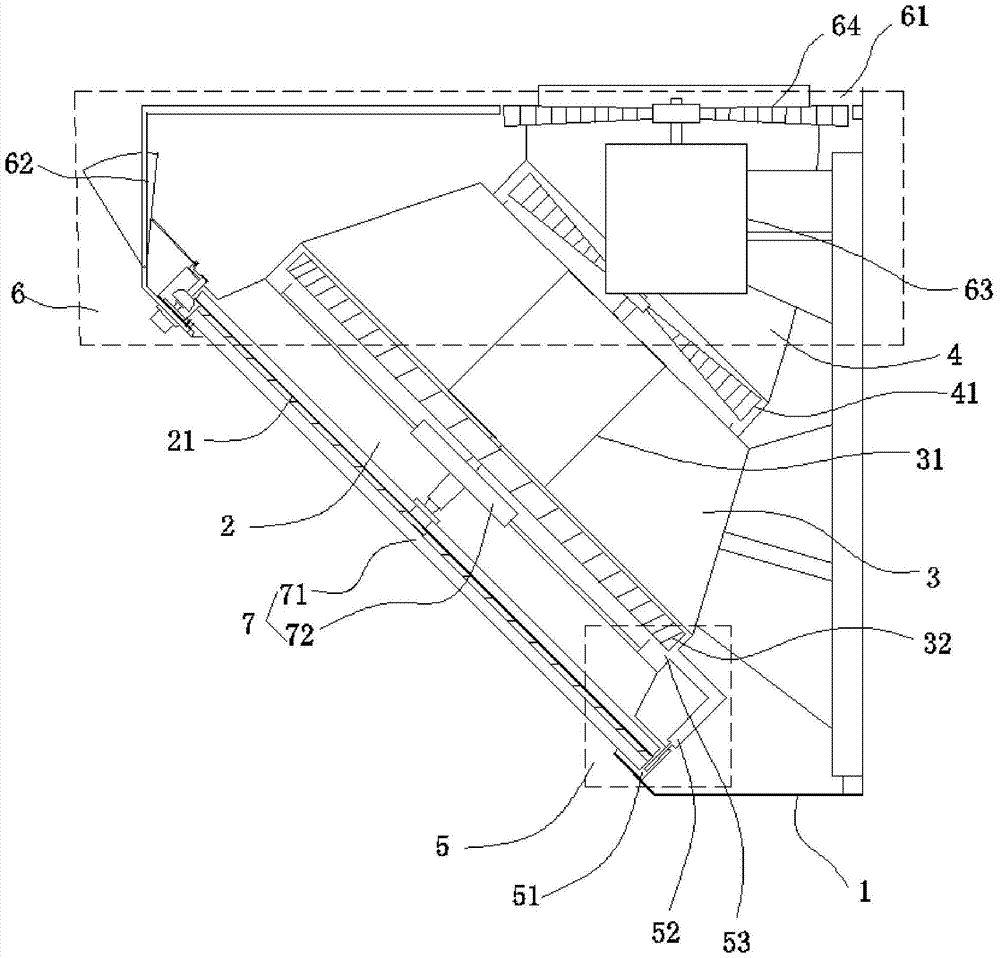

[0037] see Figure 1 to Figure 8 , a self-cleaning range hood of the present invention, comprising a casing 1, a main engine arranged in the casing 1 and separated from the inner cavity of the casing 1, the main engine includes a suction cavity 2 with a mesh plate 21, and is provided with an exhaust The motor 31 is connected to the blast chamber 3 driving the first impeller 32 , the exhaust chamber 4 connected to the blast chamber 3 and extending out of the casing 1 , the oil suction device 5 and the air supply device 6 . The air suction chamber 2 , the air blast chamber 3 and the air exhaust chamber 4 are sequentially connected and arranged in the host chamber, and the screen plate 21 is provided with an automatic cleaning device 7 .

[0038] Further, it also includes an annular groove 33 , which is arranged at the junction of the blast chamber 3 and the suction chamber 2 at the front end of the first impeller 32 , and the opening of the annular groove 33 faces the air inlet ...

Embodiment 2

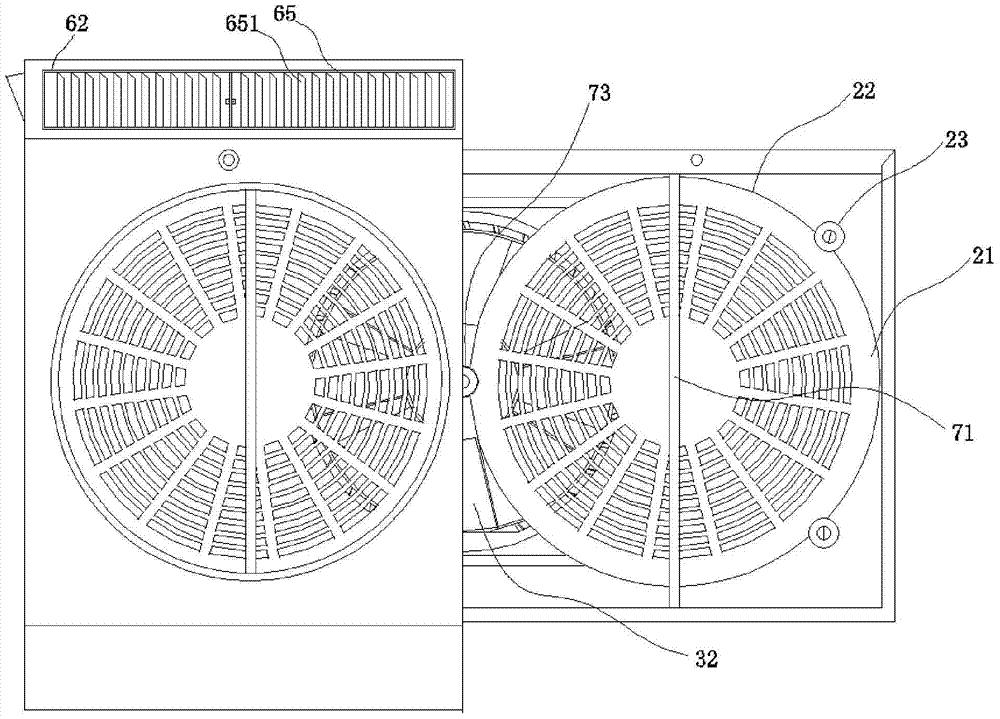

[0051] Such as Figure 9 As shown, the automatic cleaning range hood of the second embodiment is roughly the same as that of the first embodiment, the difference being that the automatic cleaning device of the second embodiment includes a rotating scraper a71, a fixed screen a21 and a speed reducer a72. The scraper a71 is in contact with the screen a21, the exhaust motor shaft is connected to the first impeller and then connected to the reducer a72, the output shaft of the reducer is connected to the rotating scraper a71, and the opposite end of the rotating scraper a71 is connected to a scraper gear ring a74 , meshes with the driving gear a73, and the driving gear a73 drives the scraper a71 to rotate. In order to stabilize the rotation of the scraper a71, a stabilizer wheel a23 is provided on the edge of the scraper gear ring a74, and the stabilizer wheel a23 meshes with the scraper gear ring a74.

[0052] Alternatively, the output shaft of the reducer a72 passes through the...

Embodiment 3

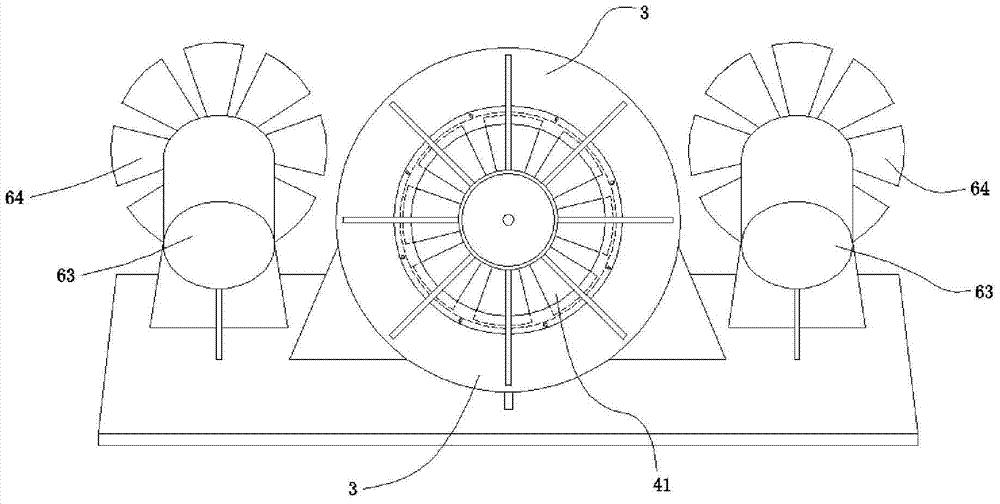

[0054] Such as Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14 As shown, Embodiment 3 is roughly the same as the automatic cleaning range hood in Embodiment 1. The difference is that in Embodiment 2, dual hosts b10 are arranged in b1 in the casing, and a blower motor b64 is arranged. The automatic cleaning device b7 includes a rotating Scraper b71, fixed mesh b21 and reducer b72. The scraper b71 is in contact with the screen b21, the exhaust motor b31 shaft is connected to the first impeller b32 and then extends into the suction chamber b2 to connect to the reducer b72, and the output shaft of the reducer b72 passes through the screen b21 to connect to the rotating scraper b71.

[0055] It also includes a lower air suction chamber b8 arranged below the air suction chamber b2, and the lower air suction chamber b8 communicates with the air suction chamber b2. The lower suction chamber b8 includes a fixed lower screen b81 and a rotating lower scraper b82, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com