Assembly type ground surface convenient for construction

A prefabricated, ground technology, applied in the direction of floor, covering/lining, insulating layer, etc., can solve the problems of inconvenient replacement of floor tiles, high cost, waste of materials and labor, etc., to improve stability, reduce processing costs, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

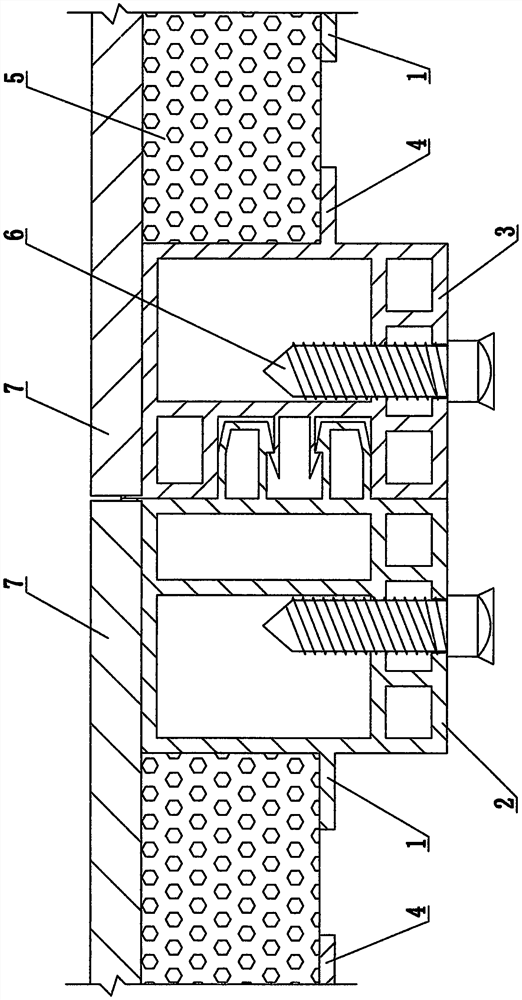

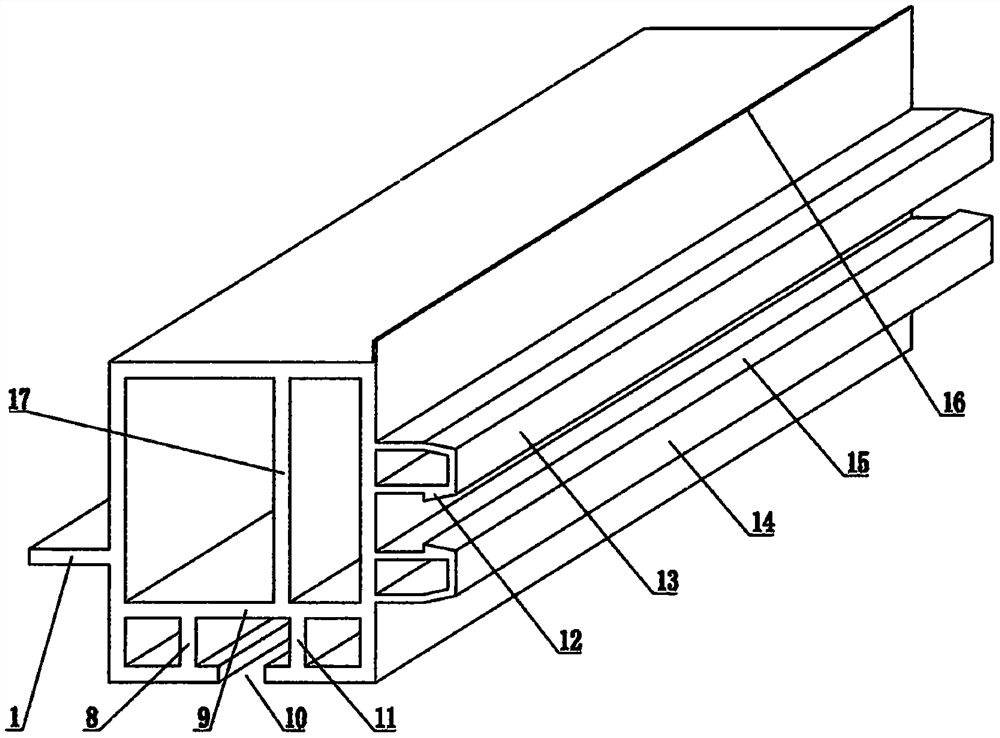

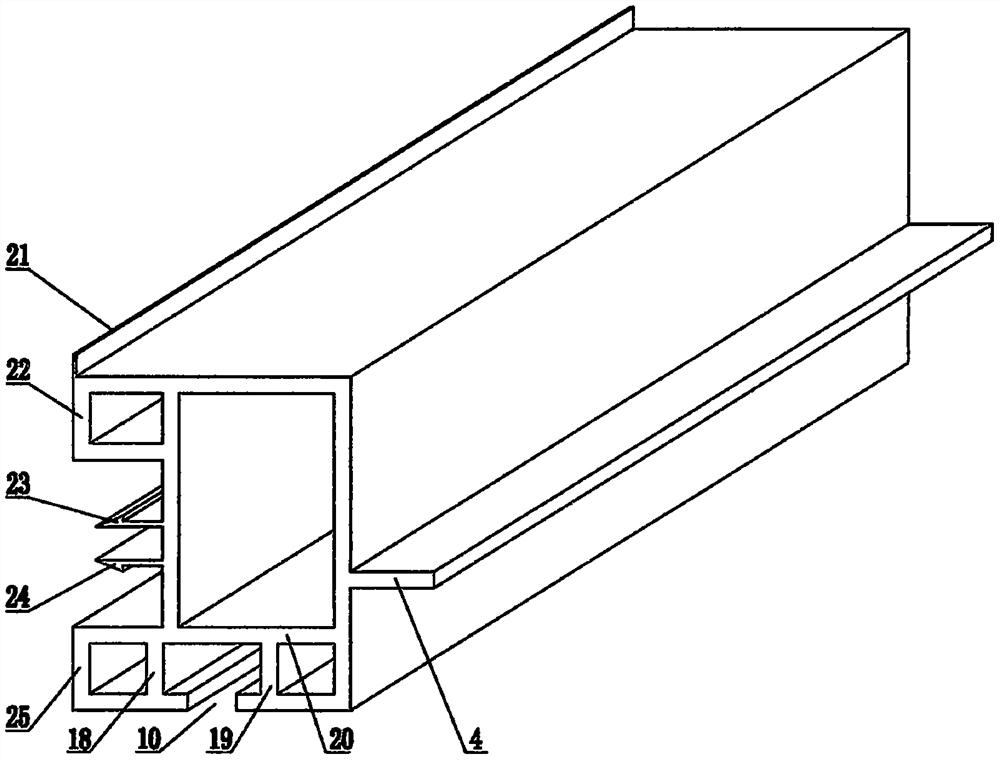

[0017] Such as figure 1 , figure 2 , image 3 As shown, this convenient prefabricated ground includes facing bricks 7 installed on A keel 2 and B keel 3 respectively. Set the first transverse rib 9 and the first longitudinal rib 17, the two ends of the first transverse rib 9 are fixedly connected with the walls on both sides of the A keel 2, and the upper and lower ends of the first longitudinal rib 17 are respectively connected with the A keel The upper wall surface of 2 is fixedly connected with the first transverse rib 9, the second longitudinal rib 8 and the third longitudinal rib 11 are arranged under the first transverse rib 9, the second longitudinal rib 8 and the third longitudinal rib 11 The two ends are fixedly connected with the lower wall surface of the A keel 2 and the first transverse rib 9 respectively. The left side of the A keel 2 extends to the left and transversely extends the first extension end 1, and the right side faces to the right and transversely e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com