Method for increasing utilization ratio of isobutene in sulfurized isobutene production

A technology for vulcanizing isobutene and isobutene, applied in the direction of organic chemistry and the like, can solve the problems of low utilization rate of isobutene, and achieve the effects of high yield, production cost saving and low transformation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

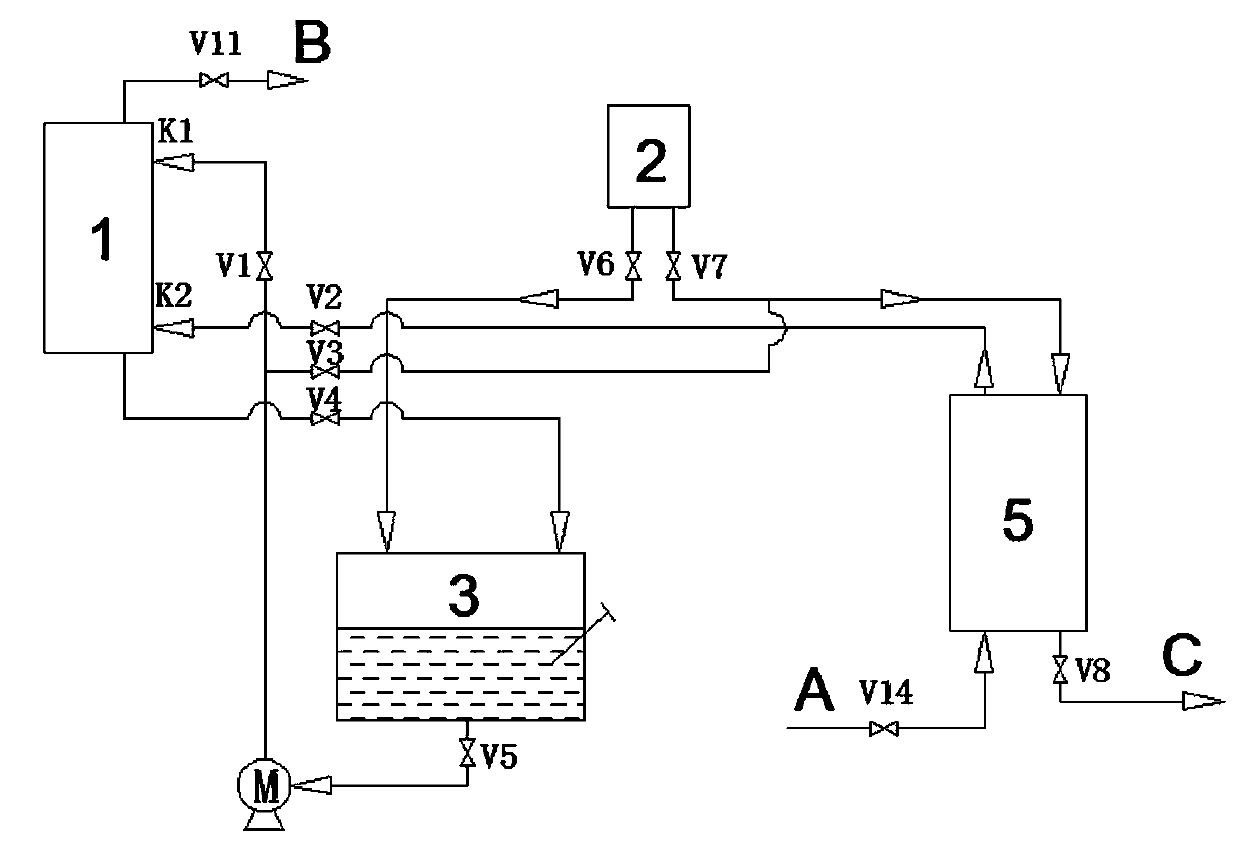

[0014] Combine below Figure 1~2 The content of the present invention is described in detail. The method for improving the utilization rate of isobutylene in the production of sulfurized isobutylene includes S 2 Cl 2 The metering tank 2, the first reaction kettle 5, the absorption tower 1, the bottom tank 3 and other parts. Among them, S 2 Cl 2 The discharge port of the metering tank 2 is connected with the feed port of the lower tank 3, and a valve V6 is set on the pipeline. The outlet of the lower tank 3 is connected to the feed end of the circulating pump M, and a valve V5 is set on the pipeline. The discharge end of the circulation pump M is connected with the feed inlet K1 at the top of the absorption tower 1, and a valve V1 is set on the pipeline. The discharge end at the bottom of the absorption tower 1 is connected to the bottom kettle 3, and a valve V4 is set on the pipeline. The top exhaust port of the absorption tower 1 is connected to the acid absorpt...

Embodiment 2

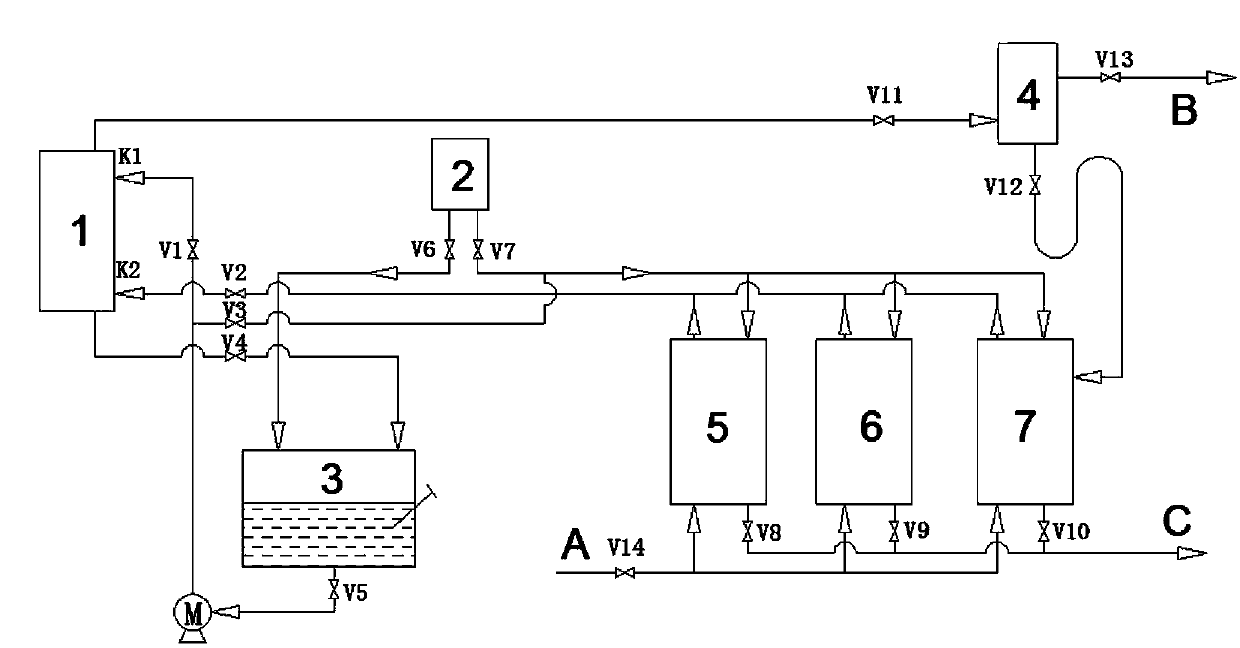

[0017] The method for improving the utilization rate of isobutylene in the production of sulfurized isobutylene includes S 2 Cl 2 Metering tank 2, first reaction kettle 5, second reaction kettle 6, third reaction kettle 7, absorption tower 1, lower tower kettle 3, gas-liquid separation device 4 and other parts. Among them, S 2 Cl 2 The discharge port of the metering tank 2 is connected with the feed port of the lower tank 3, and a valve V6 is set on the pipeline. The outlet of the lower tank 3 is connected to the feed end of the circulating pump M, and a valve V5 is set on the pipeline. The discharge end of the circulation pump M is connected with the feed inlet K1 at the top of the absorption tower 1, and a valve V1 is set on the pipeline. The discharge end at the bottom of the absorption tower 1 is connected to the bottom kettle 3, and a valve V4 is set on the pipeline. The top exhaust port of the absorption tower 1 is connected with the gas-liquid separation dev...

Embodiment 3

[0020] This embodiment optimizes embodiment 1, and 26mol% ~ 33mol% S 2 Cl 2 Pass into the lower kettle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com