Electromagnetic hot air furnace

A technology of hot blast stove and electromagnetic heater, which is applied in the direction of air heater, fluid heater, lighting and heating equipment, etc. It can solve the problems of polluted air, low heat exchange efficiency and complex structure, and achieve the effect of huge market development potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

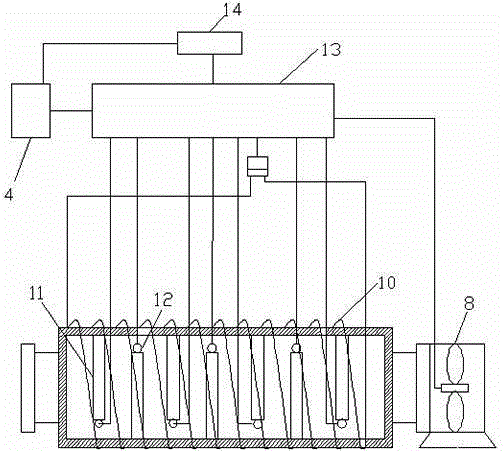

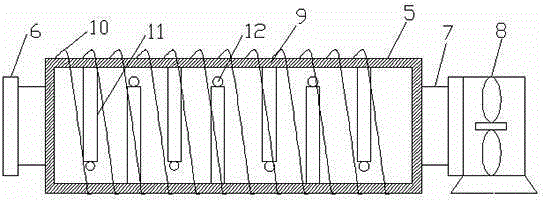

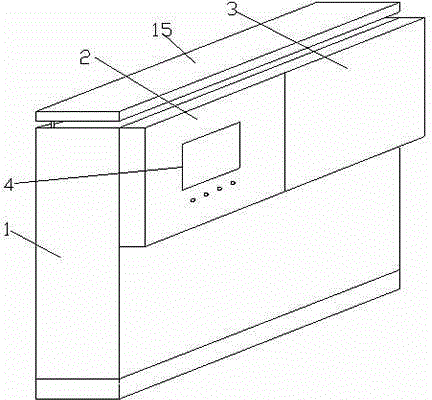

[0013] Such as figure 1 , figure 2 and image 3 As shown, an electromagnetic hot air stove is mainly composed of a cabinet 1, an operation cabinet 2, a control cabinet 3 and an electromagnetic heater. The operation cabinet 2 and the control cabinet 3 are arranged at the front of the cabinet 1, and the electromagnetic heater is built into the cabinet. 1 inside, the top cover 15 is set on the top of the box body 1, the touch screen 4 is set on the operation cabinet 2, the PLC controller 13 is built in the control cabinet 3, the electromagnetic heater includes a cylinder 5, and the two ends of the cylinder 5 are respectively equipped with an air inlet 6 and an outlet The tuyere 7 and the air outlet 7 are connected to the centrifugal fan 8, the inner side of the cylinder 5 is provided with an insulating layer 9, several electromagnetic induction coils 10 surround the surface of the cylinder 5 and are connected to the PLC controller 13, and the inside of the cylinder 5 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com