A trough solar concentrator based on variable cross-section beams

A trough solar, variable-section beam technology, applied in solar collectors, solar collector controllers, solar thermal energy, etc., can solve the problem of high investment costs, achieve low cost, improve light concentration accuracy, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

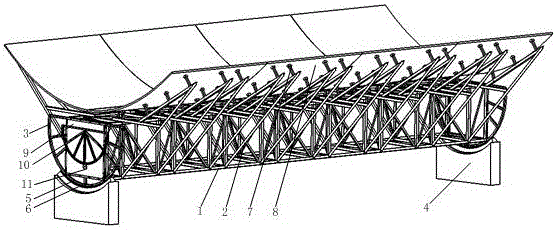

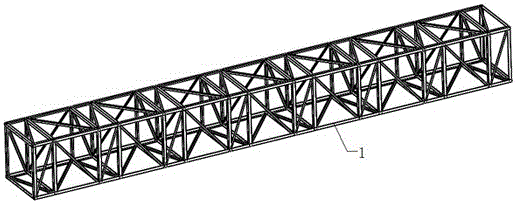

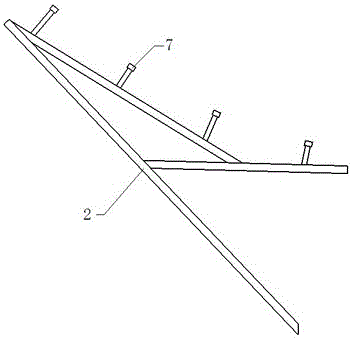

[0022] Such as Figure 1-6 Shown: a trough solar concentrator based on variable cross-section beams, including a reflective mirror 8 mounted on a mirror support carrier 7 welded by section steel, the surface of the reflective mirror 8 is a parabolic type, and the reflective mirror 8 The surface shape of the mirror surface support carrier 7 is consistent with that of the mirror surface support carrier 7 to ensure the installation accuracy of the reflection mirror surface 8; the steel cantilever beam 2 is welded to it under the mirror surface support body 7, and the cantilever beam 2 is symmetrically installed on the two sides of the rectangular space truss 1. On the side, the rectangular space truss 1 and the cantilever beam 2 are respectively welded by section steels of different cross-sectional sizes, and the beam cross-section size of the rectangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com