Quenched steel machining white layer detection method based on electrochemical detection device

A detection device and detection method technology, applied in the direction of electrochemical variables of materials, etc., can solve the problems of difficulty in detecting white layer and cannot be an effective detection method, and achieve the effect of simple experimental device and easy test method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

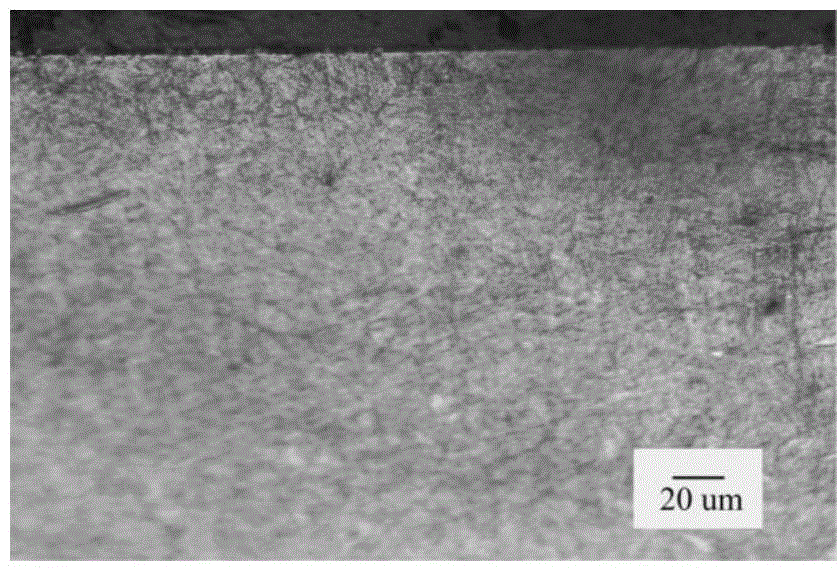

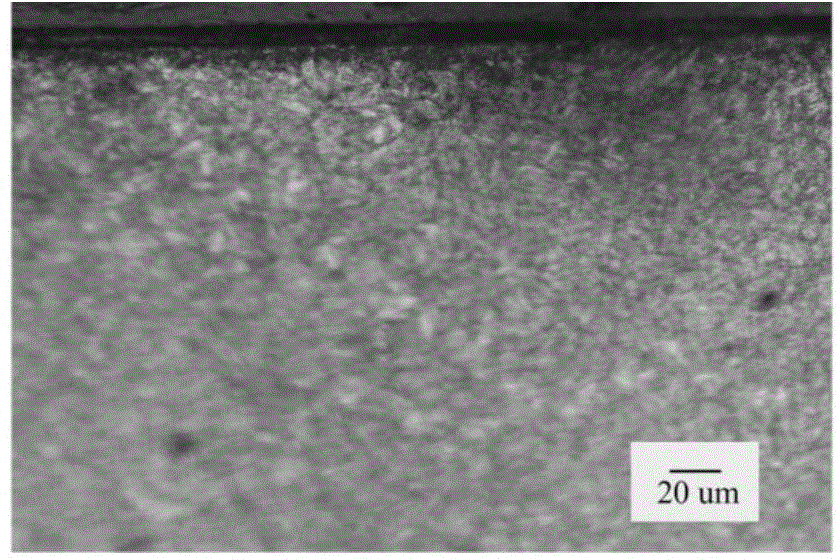

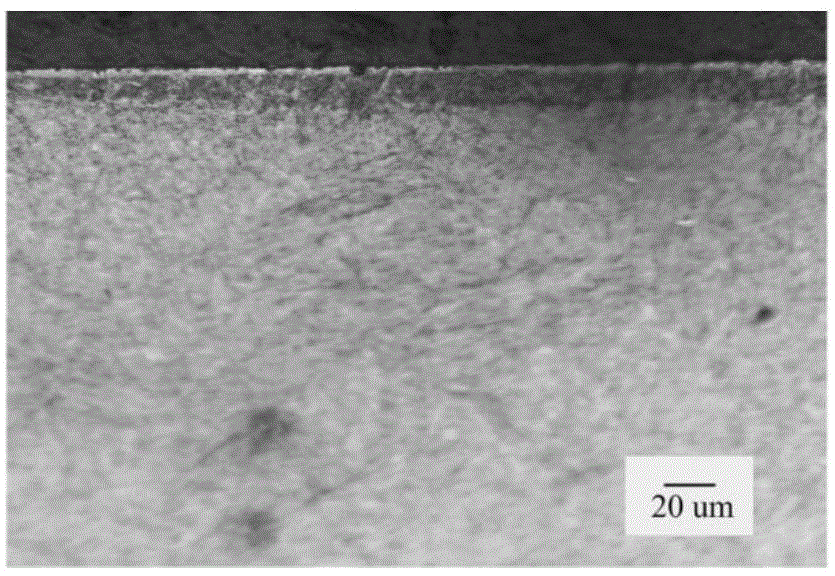

This embodiment takes the detection of the hard milling white layer of the hot work die steel AISI H13 as an example.

As shown in Figure 6, a white layer detection method for hardened steel processing based on an electrochemical detection device includes the following steps:

Step (1): Select the hardened steel to be tested, and make an electrochemical detection device;

Step (2): Measure the AC impedance spectrum of the hardened steel to be tested to obtain the charge transfer resistance;

Step (3): judging whether there is a white layer structure on the surface layer of the hardened steel to be tested;

Step (3.1): Presetting the characteristic value range of the processed white layer of hardened steel to be measured;

Step (3.2): If the charge transfer resistance value obtained in step (2) is within the range of the white layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com