Spouted fluidized bed with tar catalytic cracking function

A spouted fluidized bed and catalytic cracking technology, which is applied in catalytic cracking, cracking, petroleum industry, etc., can solve the problems of complex catalytic cracking tar device, difficult control of solid particle distribution, uneven temperature distribution in the bed, etc., and achieve the overall structure The design is compact and ingenious, the pyrolysis reaction is thorough, and it is easy to popularize and apply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding of the present invention, the present embodiment will be described in detail below with reference to the accompanying drawings.

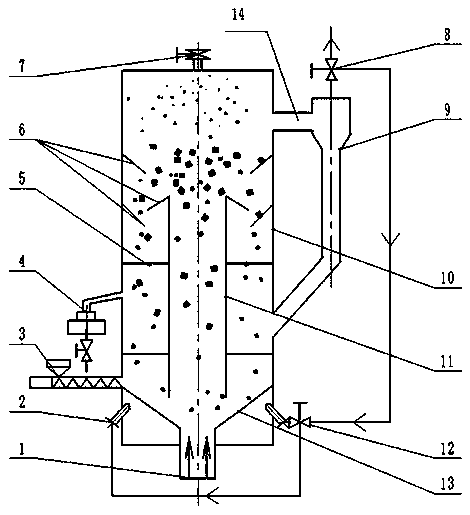

[0020] see figure 1 , a spouted fluidized bed with tar catalytic cracking function, comprising a spouted fluidized bed body 10, a semi-coke feed port 7 and a pyrolysis gas outlet 14 in the upper and upper section of the bed body; a semi-coke collector in the middle section Tank 4, gas-solid separator 9, gas inlet pipe and screw feeder 3 are arranged in the lower section; guide pipe 11 is arranged in the spouted fluidized bed body 10, and the semi-coke feed port 7 is arranged in the spouted fluidized bed At the top of the bed body 10, the guide pipe is connected in the spouted fluidized bed body 10 through the support rod 5, and the gas-solid separator 9 and the semi-coke collection tank 4 are respectively arranged on both sides of the spouted fluidized bed body 10; The guide pipe 11 is fixed by four symme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com