Traceability system suitable for PCB manufacturing

A traceability system and two-dimensional code technology, which can be applied in the direction of collaborative operation of devices, instruments, computer parts, etc., and can solve problems such as difficult production conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

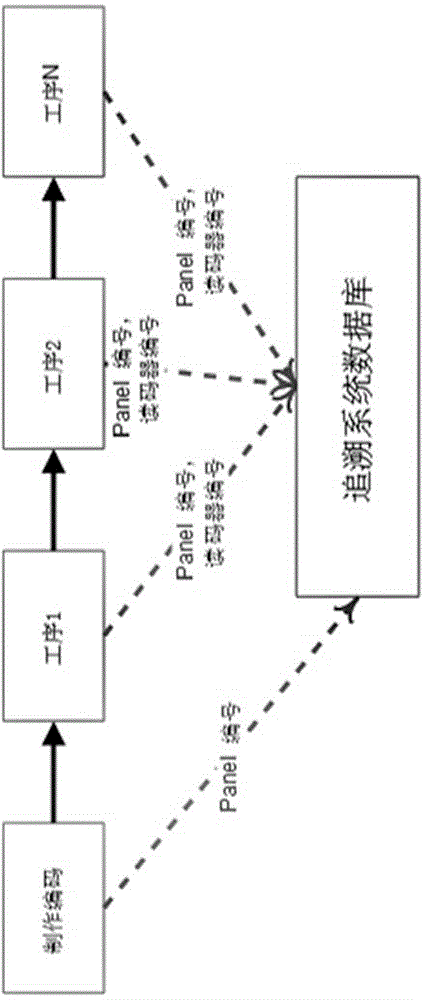

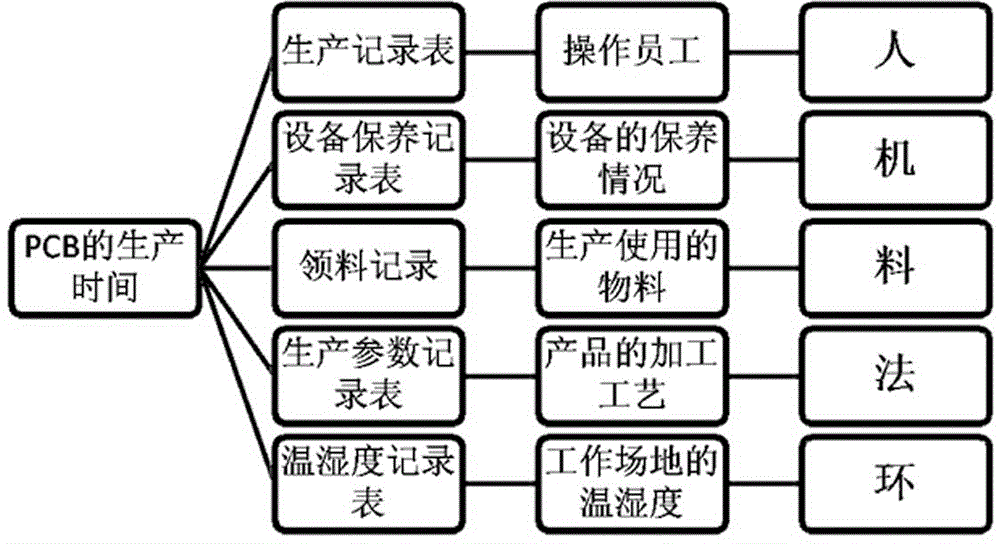

[0013] A traceability system suitable for PCB manufacturing, including multiple two-dimensional code production equipment installed at the beginning of the production line, before the lamination process, after the lamination process, and before the forming and shipping process, and the equipment feeding equipment set in each production process The two-dimensional code reader at the entrance and the traceability system database, the two-dimensional code production equipment, and the two-dimensional code reader are all connected to the traceability system database; each two-dimensional code production equipment will be produced on the two-dimensional The coding information is stored in the traceability system database; a new independent two-dimensional code is adopted after each lamination process is completed; when the PCB enters the production process after the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com