Equipment gas leakage monitoring system and method based on artificial intelligence sense

A technology of gas leakage and artificial intelligence, applied in liquid tightness measurement using liquid/vacuum degree, detecting the appearance of fluid at the leakage point, etc., can solve problems such as difficult online monitoring, easy interference, limited monitoring range, etc. problems, to avoid unplanned downtime, broad application prospects, and high recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with specific examples and accompanying drawings, which are explanations rather than limitations of the present invention.

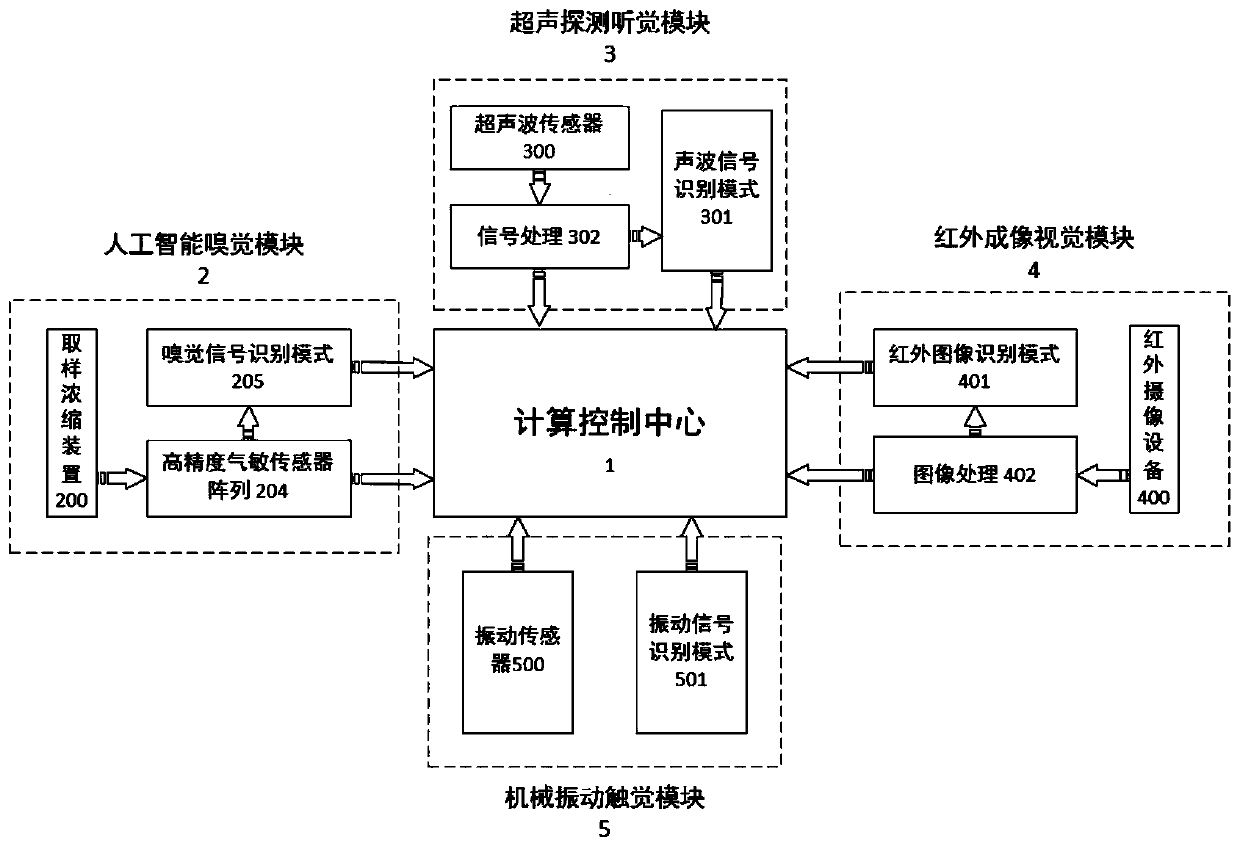

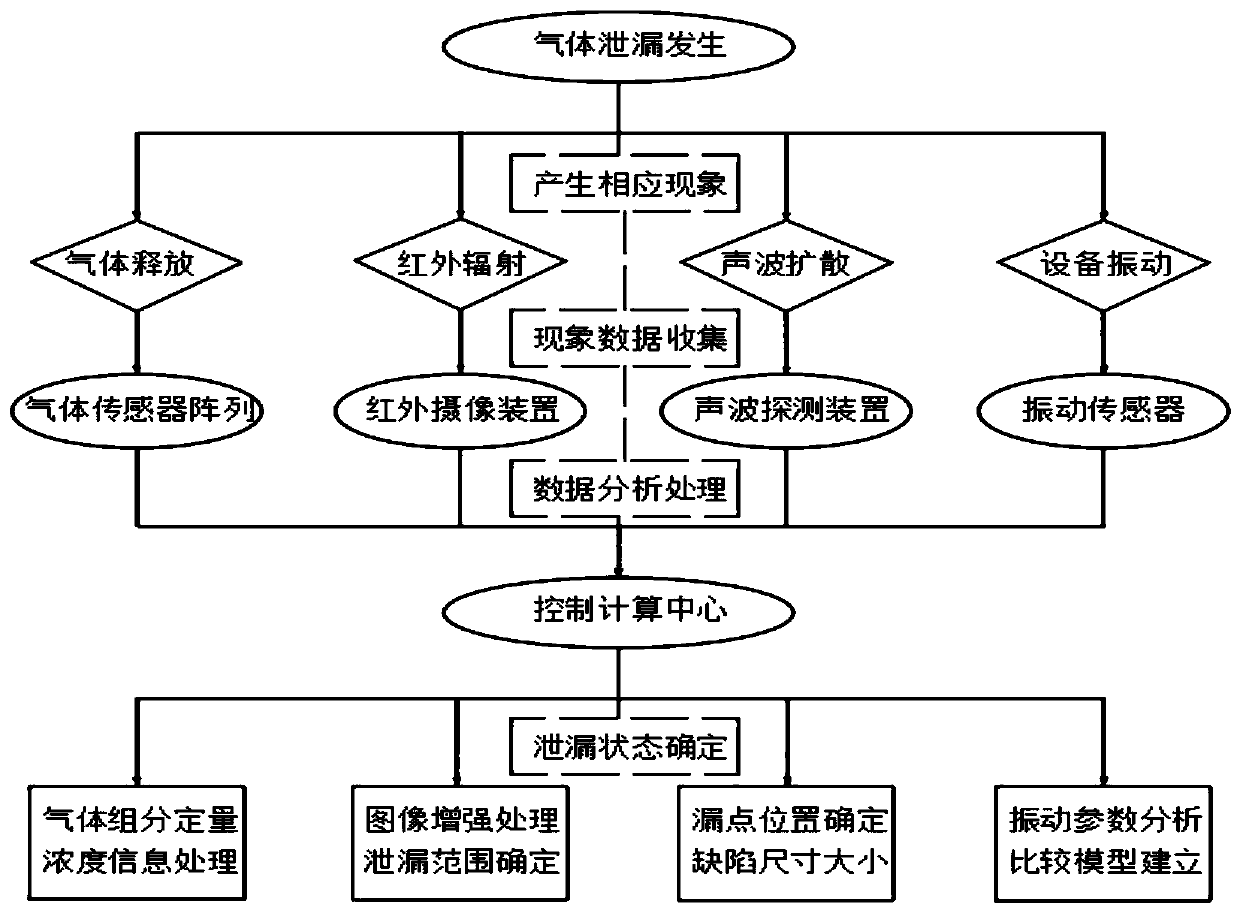

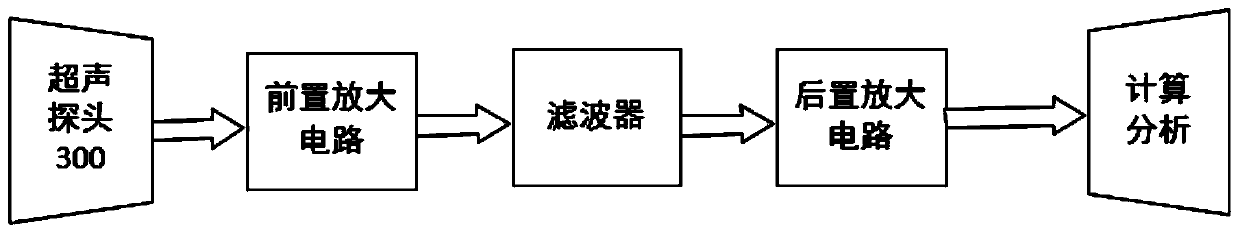

[0056] An equipment gas leakage identification and monitoring system of the present invention is composed of four parts: artificial intelligence sense of smell, infrared imaging vision, ultrasonic detection sense of hearing and mechanical vibration sense of touch. Among them, the artificial intelligence sense of smell is through the adsorption of odor molecules by the sensor array in the artificial olfactory system to generate a signal. The electrical signal generated by the sensor is amplified by the electronic circuit and A / D converted into a digital signal input to the computer. The signal output by the sensor array is passed through a special After the software collects, processes, and processes, it compares and identifies the known information collected after "human...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com