Solar cover plate glass

A cover glass and solar energy technology, which is applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of not being able to effectively improve the transmittance, increase the reflectivity, and reduce the glass transmittance, so as to improve the overall light transmittance Ratio, reduce the reflection angle, reduce the effect of reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

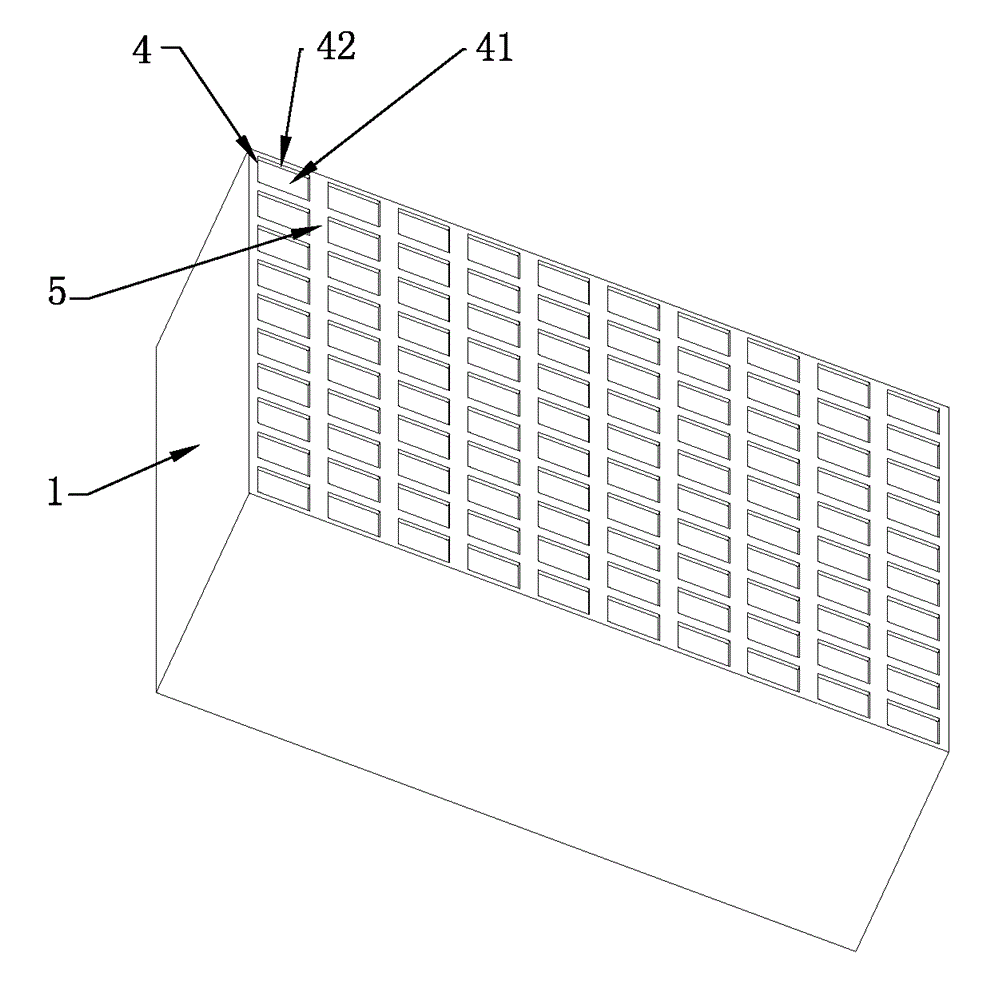

Image

Examples

Embodiment

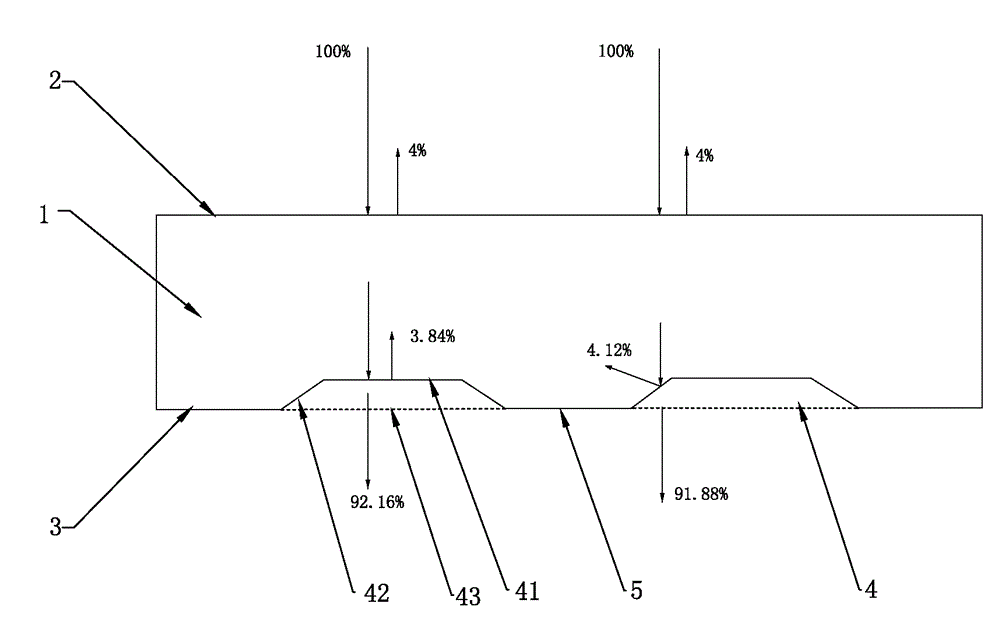

[0042] The third specific embodiment of a solar cover glass created by the present invention, the main technical solution of this embodiment is the same as that of embodiment 2, and the features not explained in this embodiment shall be explained in embodiment 2, here No further details will be given. The difference between this embodiment and embodiment 2 is that, as Figure 4 As shown, the section is a curved surface of an arc, and the inclination angle α between the secant of the section of the groove wall 42 and the bottom surface 3 of the panel body 1 is greater than 120°.

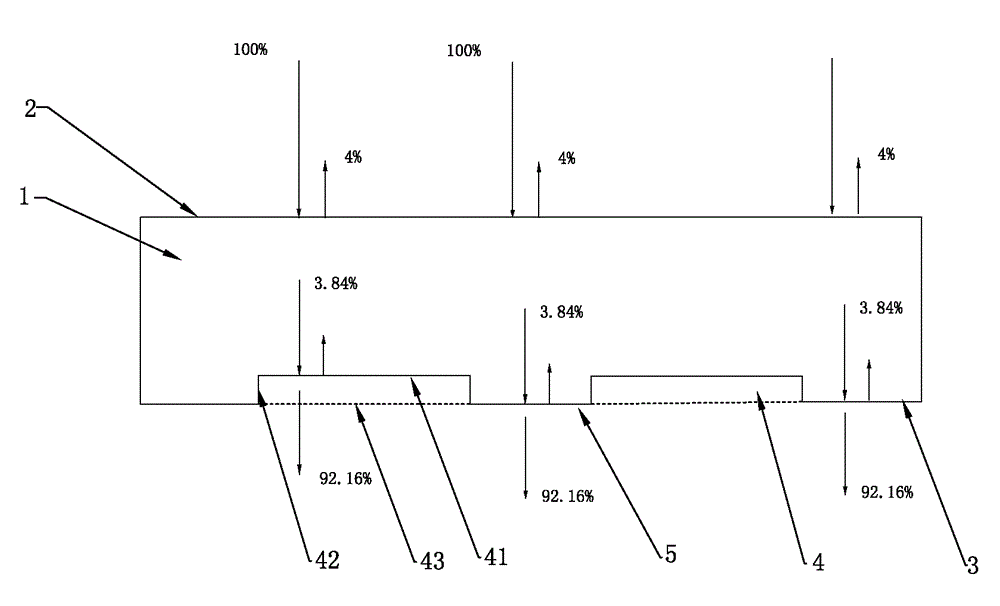

[0043] For this embodiment, when the light is vertically incident on the cover glass, part of the light will be reflected on the upper surface of the cover glass, the reflected part is about 4%, and the remaining 96% enters the cover glass. The glass propagates vertically downward, part of which reaches the bottom surface 3 of the cover glass, part of which reaches the bottom 41 of the groove 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com