Elastic press roller with soil crashing function

A technology for crushing rollers and crushing soil, which is applied to compactors, agricultural machinery and implements, and agriculture. It can solve problems such as increasing soil disturbance and damage, affecting seed germination and growth, and soil moisture loss, so as to improve operating efficiency and improve operating efficiency. Quality, the effect of reducing the degree of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

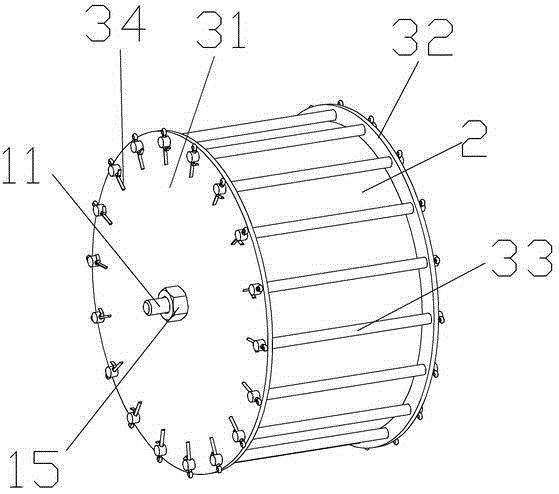

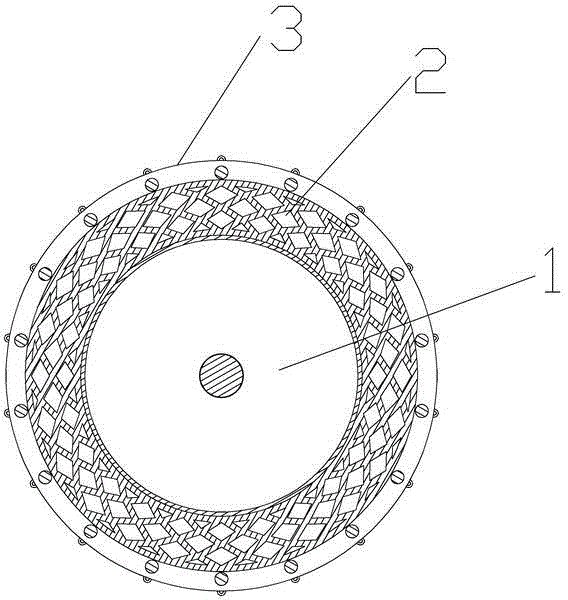

[0020] see figure 1 and figure 2 As shown, the present invention is composed of a wheel hub welding device 1, a hole structure elastic body 2 and a soil breaking device 3, the hole structure elastic body 2 is arranged on the outer surface of the wheel hub welding device 1, and the soil breaking device 3 is fixedly arranged on the wheel hub On the welding device 1;

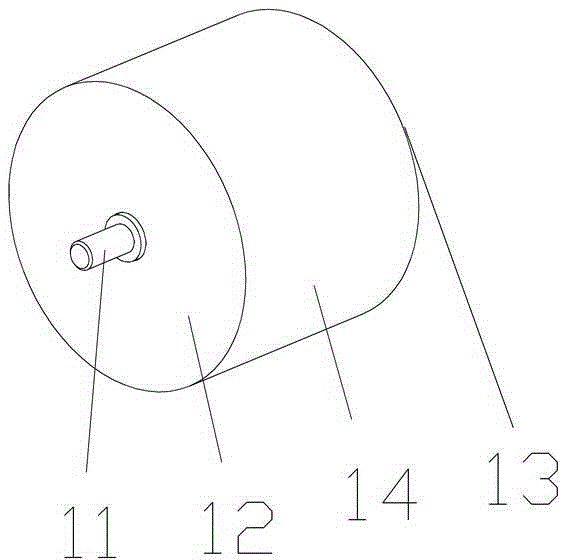

[0021] Such as image 3 As shown, the hub welding device 1 includes a central shaft 11, a first end cap 12, a second end cap 13 and a cylinder 14, and the first end cap 12 and the second end cap 13 are fixedly arranged at both ends of the cylinder 14, respectively. The central axis 11 is arranged in the cylinder 14;

[0022] The hole structure elastic body 2 is arranged on the outer surface of the hub welding device 1, and in the soil breaking device 3, the hole structure elastic body 2 is in the shape of a ring, and its interior is a random polygon hole structure;

[0023] Such as Figure 5 As shown, the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com