Device and method for turning rod-shaped articles in the tobacco processing industry

A technology for the processing industry and shaped products, applied in the field of equipment and methods for turning rod-shaped products in the tobacco processing industry, capable of solving complex and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

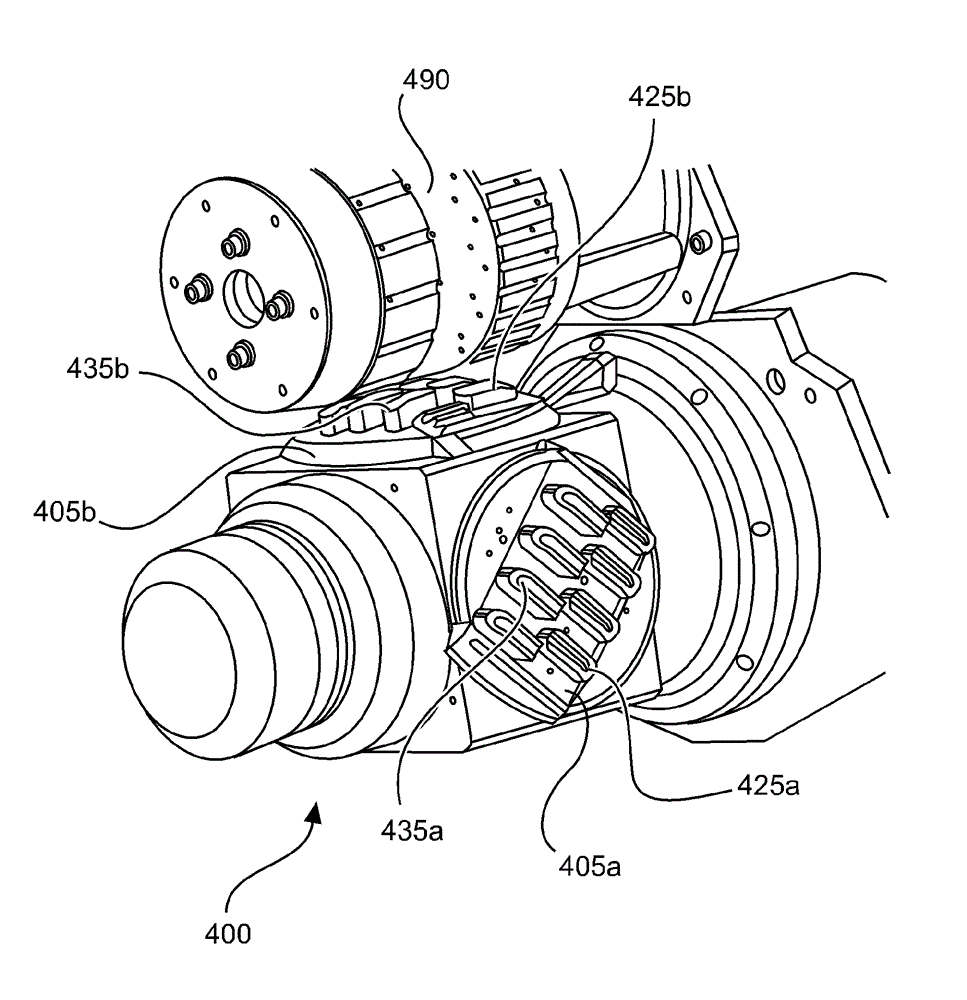

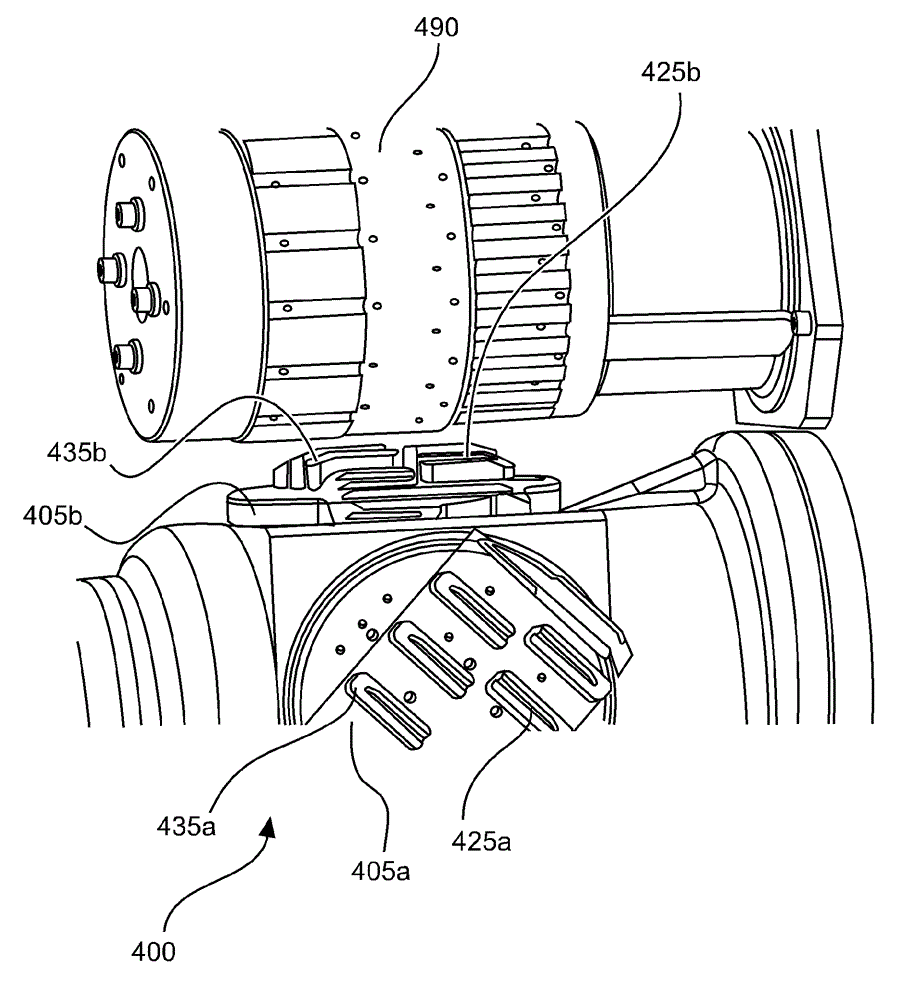

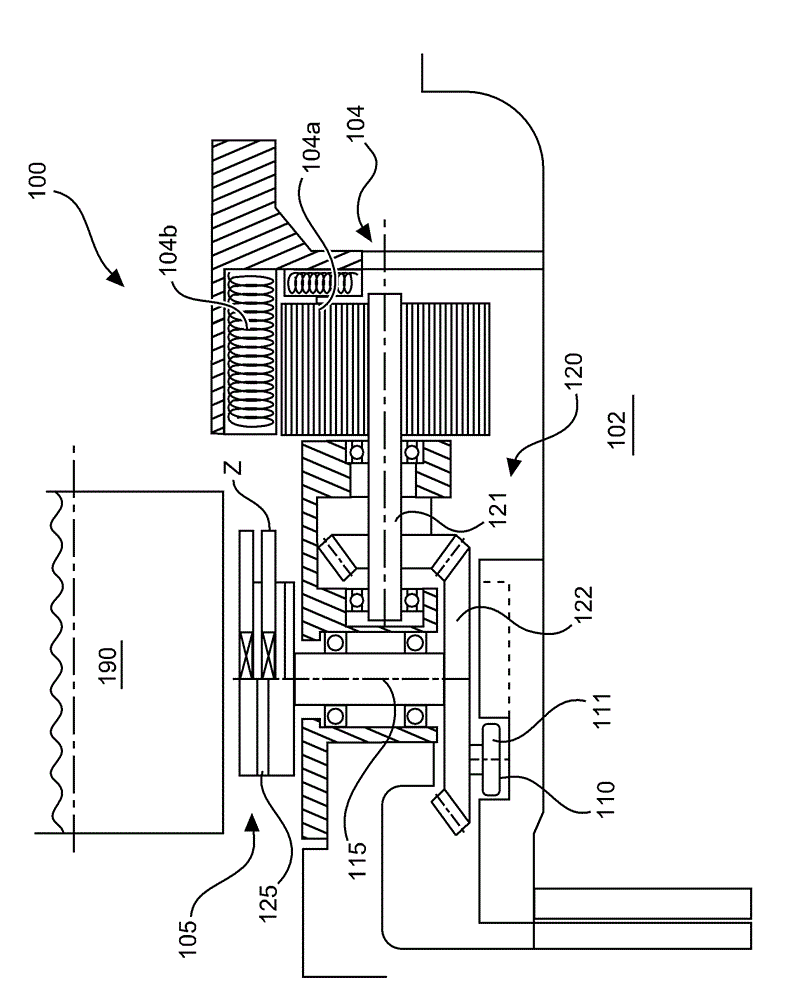

[0050] exist figure 1 A cross section of a part of a first possible embodiment of the device 1 for deflecting cigarettes Z according to the invention is shown in . A drum shaft 2 designed as a hollow shaft is mounted in the machine housing 12 . The roller shaft 2 will be in figure 1 The drum chamber on the right in the figure 1 It is connected to the machine chamber on the left and the back in the center. The drum shaft 2 is driven by a drum drive designed as a belt drive 3 (or gear stage). The drum drive can be designed not only as an individual drive for a drum shaft or deflection drum, but also as an overall drive for several drum shafts or deflection drums.

[0051] In the drum chamber, in a fixed connection to the drum shaft 2 , there is an electric drive 4 designed as an electric motor which rotates together with the drum shaft 2 . The electric motor 4 drives the deflection section 5 in such a way that it rotates about its axis of rotation, which is perpendicular to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com