Material suction and discharge crushing fan

A material crushing and material technology, which is applied in the field of material suction, discharge and crushing fans, can solve the problems of inability to meet the needs of use, narrow use range, crushing processing, etc., and achieve the effect of saving raw materials, using multiple functions, and simple mechanical equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

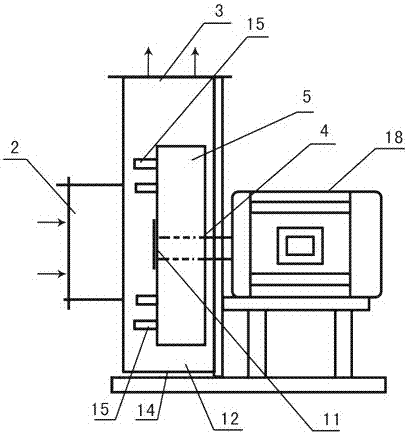

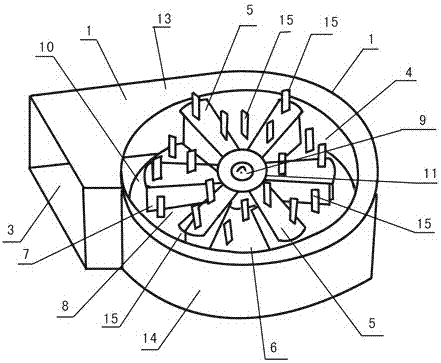

[0050] Embodiment 1, reference figure 1 , figure 2 , The material suction and discharge crushing fan includes a casing 1, a casing air inlet 2, and a casing air outlet 3. The casing is provided with a synchronous backflow fan impeller 4, and the impeller 4 is provided with impeller blades 5, and a reinforcing disk 11 in the middle of the impeller. Impeller air outlet 6, blade air outlet 7, impeller inner flow channel 8, impeller shaft sleeve 9, impeller blade disc 10, casing inner flow channel 12, impeller blade 5 (blade synchronous deflector is provided on the blade) and blade synchronization Blade-type material crushing teeth 15 are provided on the deflector, blade-type material crushing teeth 15 are provided on the impeller blade disc 10 in the inner flow channel 8 of the impeller, and a motor 18 is provided at the rear of the body, and the shaft of the motor 18 passes through the impeller shaft sleeve 9 is connected with impeller 4.

[0051] This example is used for the...

Embodiment 2

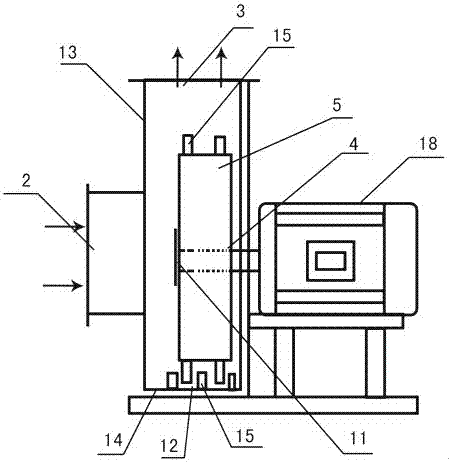

[0055] Embodiment 2, refer to image 3 , Figure 4 , this example is basically the same as Example 1, the difference is that there are no material crushing teeth on the axial side of the impeller blades in this example, but a blade type material is set on the casing radial side wall 14 of the casing inner flow channel 12 The crushing teeth 15 are provided with blade-type material crushing teeth 15 on the edge of the impeller blade disk 10 of the impeller air outlet 6, and the blade-type material crushing teeth 15 are set on the blade air outlet 7. This example is used for suction and discharge of broken, soft and fragile materials, such as plastic foam, melons and fruits, leaves, vegetable leaves, etc.

[0056] When working, the high-speed flowing soft and fragile materials discharged by the impeller in the inner flow channel of the casing collide with the material crushing teeth 15 rotating at high speed at the blade air outlet 7 and the edge of the impeller blade disc 10, a...

Embodiment 3

[0059] Embodiment 3, refer to Figure 5 , Image 6 , this example is the same as Example 1, the difference is that there is no material crushing tooth on the axial side wall of the impeller blade in this example, and a cylindrical material crushing tooth connecting piece 16 is set on the middle reinforcement plate 11 of the impeller in this example, and the cylindrical material The crushing tooth connecting piece 16 protrudes along the axial direction and extends into the air inlet 2 of the casing. The material crushing tooth connecting piece 16 is surrounded by a three-edged knife-type material crushing tooth 15 fixed on the material crushing tooth connecting piece, and the middle reinforcement plate of the impeller 11 forms an indirect connection structure with the material crushing teeth 15, and the reinforcement disc 11 in the middle of the impeller drives the material crushing teeth 15 to rotate at high speed. Material crushing teeth 15 are arranged on the inner wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com