Novel automatic flat-plate film-coating machine

A technology of scraping film and flat plate, which is applied in the coating, the device for coating liquid on the surface, etc., can solve the problem that the gap between the scraper and the scraping plate cannot be kept constant continuously, the film thickness cannot be accurately controlled, and the film liquid on the scraper is inconvenient to clean. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

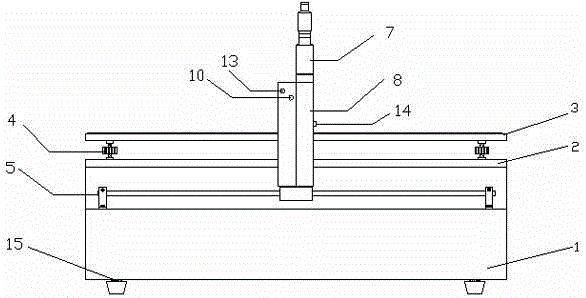

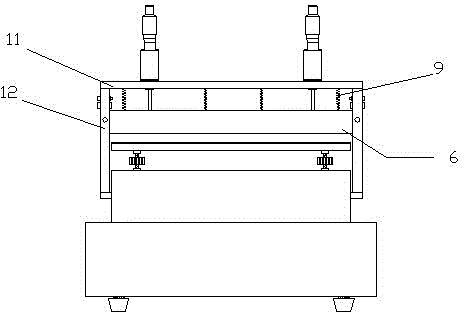

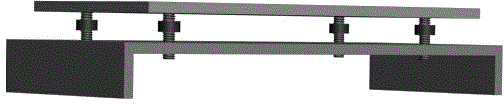

[0023] The new automatic flat film scraping machine of this example includes: a base (1), a scraping table (2), a flat scraper (3), a flat scraper adjustment device, a scraper unit, and a drive unit.

[0024] A new type of flat film scraping machine, the bottom of which is a cuboid base (1) for supporting the whole scraping machine, the level of the base (1) is adjusted by adjusting the base lifting rod (15). The film scraping table (2) is located above the base (1). The film scraping table (2) and the film scraping plate (3) are connected by four double-helix screws (4), and the film scraping is adjusted by rotating the double-helix screws (4). The height and level of the slab (3). The scraper (6) is suspended below the scraper bracket crossbeam (11) by two springs (9), and the two spiral micrometers (7) on the crossbeam (11) are against the top of the scraper (6), and the spiral micrometer (7) Used to adjust the height and level of the scraper. After the position of the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com