Device for preventing lathe chuck spanner from being thrown out

A lathe chuck and wrench technology, applied in the field of lathes, can solve the problems of the chuck wrench flying out and hurting people, and achieve the effect of preventing the flying out and hurting people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

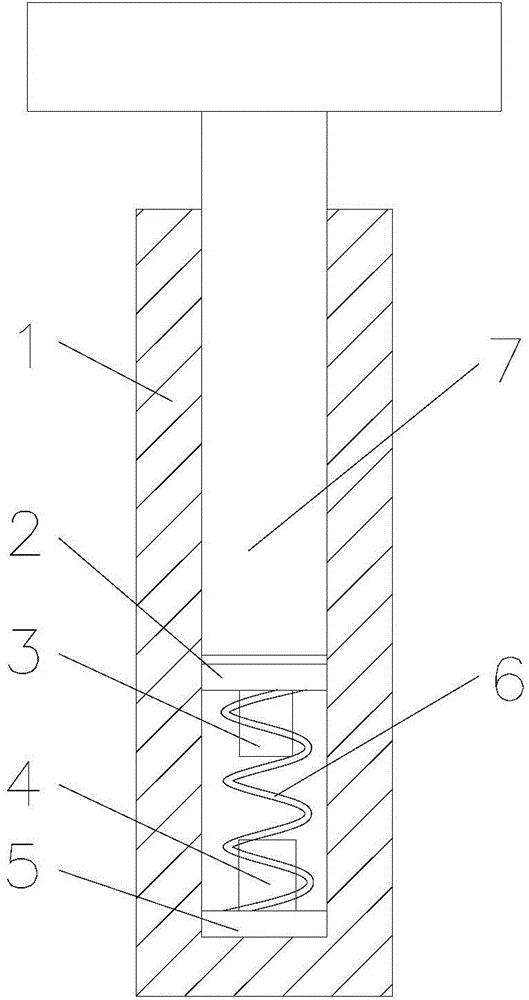

[0012] Such as figure 1 A device for preventing lathe chuck wrench throwing out is shown, including a bed and a sleeve 1 with a hollow cavity arranged on the bed, and a first pressure plate 5 and a second pressure plate 2 are arranged in the hollow cavity, and the first pressure plate 5 is arranged in the hollow cavity. The second pressure plate 2 is located above the first pressure plate 5, a return spring 6 is arranged between the first pressure plate 5 and the second pressure plate 2, and a first conductive Block 4, the second platen 2 is provided with a second conductive block 3 opposite to the first conductive block 4, the first conductive block 4 and the second conductive block 3 are connected in series in the main circuit of the machine tool, so The first pressing plate 5, the second pressing plate 2 and the return spring 6 are all insulators. When the chuck wrench 7 is inserted into the sleeve 1, the chuck wrench 7 will press the second pressing plate 2 to the first pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com