Device and method for adjusting longitudinal thickness uniformity of extruded composite film

A technology of extrusion compounding and uniform thickness, which is applied in the field of longitudinal thickness uniformity adjusting devices for extruded compound films, and can solve the problem of adjusting the same proportional relationship of the motor speed under the open-loop control of the inverter, adjusting the relationship of the motor speed under the open-loop control of the inverter, The problem of large longitudinal thickness deviation of the film, etc., can achieve the effect of accurate and fast test results, improved production efficiency, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

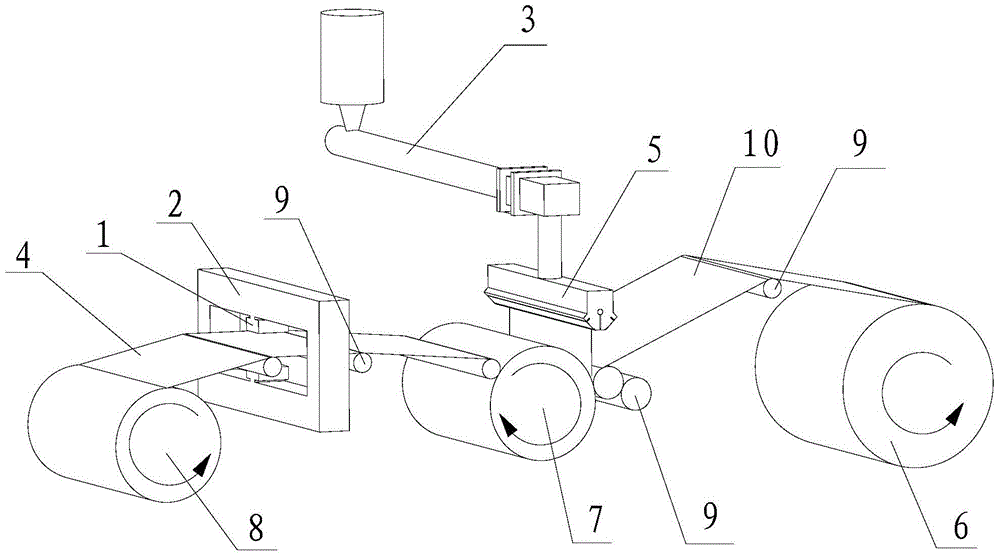

[0029] This embodiment is a device for adjusting the longitudinal thickness uniformity of an extruded composite film, such as figure 1 As shown, including the thickness gauge (the overall structure is not shown in the figure), the probe mounting frame 2, the extruder 3, the PLC controller (not shown in the figure) and the film conveying mechanism, the probe 1 of the thickness gauge passes through the probe It is installed and erected on the surface of the extruded composite film 4, the thickness gauge and the extruder are respectively electrically connected with the PLC controller, the extruded composite film is conveyed through the film conveying mechanism, and the die of the extruder is set above the film conveying mechanism.

[0030] The thickness gauge can be a non-contact thickness gauge available on the market, and the probe in the thickness gauge moves back and forth along the transverse section of the extruded composite film.

[0031] The probe mounting frame is an O-frame, ...

Embodiment 2

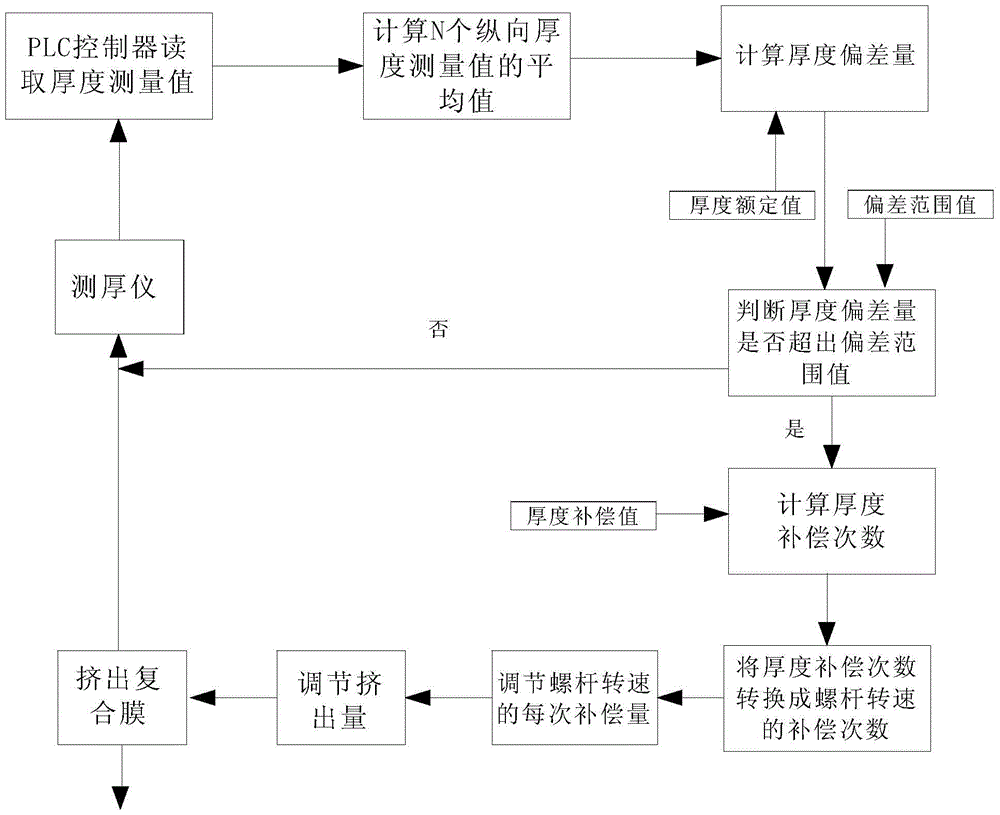

[0037] In this embodiment, a method for adjusting the longitudinal thickness uniformity of an extruded composite film is realized by the device described in Example 1. The thickness of each point of each transverse section in different lengths of the extruded composite film is measured by a thickness gauge in real time, and then controlled by PLC The device compares and analyzes the measured thickness values with the preset thickness values, and then converts the analysis results into the screw speed control of the extruder, and then controls the extrusion volume at the extruder die, and finally realizes extrusion Real-time adjustment of the longitudinal thickness of the composite film.

[0038] Among them, the PLC controller compares and analyzes the measured thickness values with the preset thickness values as follows: figure 2 As shown, it specifically includes the following steps:

[0039] (1) Pre-set the thickness rating, deviation range value and thickness compensatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com