Novel composite bearing for forklifts

A technology of composite bearings and forklifts, which is applied in the direction of bearings, shafts and bearings, bearings for rotational motion, etc., can solve the problems of many parts, low service life, inconvenient assembly and processing, etc., to reduce parts, ensure accuracy, The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

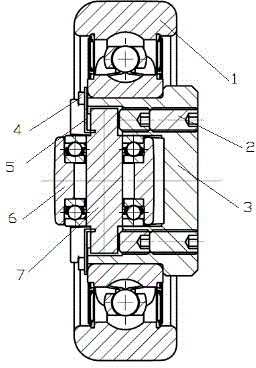

[0024] like figure 1 , figure 2 As can be seen from the schematic diagram shown, the first structure of the composite bearing for a forklift of the present invention includes a main roller 1 , a shaft head 3 and a side roller 6 .

[0025] The main roller 1 is sleeved on the shaft head 3, and an annular limit groove is opened on one side of the top end surface of the shaft head 3, and an annular installation groove is opened at the corresponding position of the inner wall of the main roller 1. One side of the inner ring of the main roller 1 The position is limited by the stepped surface of the shaft head 3 itself, and the other end is limited by the retaining ring 4 embedded in the limit groove and the installation groove.

[0026] By directly installing the side roller 6 on the shaft head 3, this structure removes the side roller bracket, thereby reducing the components of the overall bearing, making the structure simple, and the corresponding assembly and processing are mor...

Embodiment 2

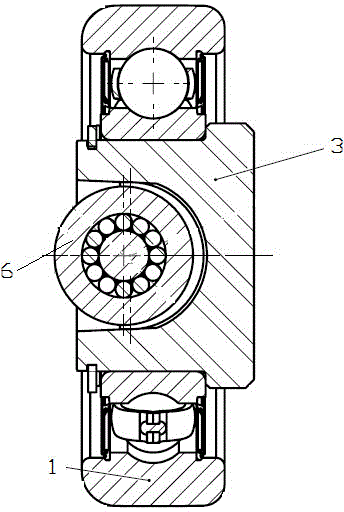

[0032] like Image 6 , Figure 7 As can be seen from the schematic diagram shown, the second structure of the composite bearing for a forklift of the present invention includes a main roller 11 , a shaft head 12 and a side roller 15 .

[0033] The main roller 11 is sleeved on the shaft head 12, one side of the inner ring of the main roller 11 is limited by the stepped surface of the shaft head 12 itself, and the other end of the main roller 11 is limited by the adjustment limit mechanism connected with the shaft head 2. .

[0034] By directly installing the side roller 11 on the shaft head 12, such a structure removes the side roller bracket, thereby reducing the components of the integral bearing, making the structure simple, and the corresponding assembly and processing are relatively convenient.

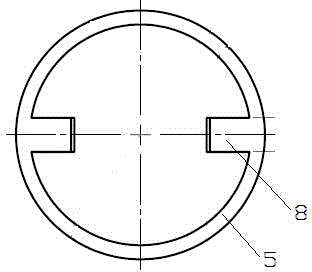

[0035] Depend on Figure 9 As can be seen from the schematic diagram shown, there is an inner cavity 19 with a cross-shaped cross section on the top surface of the shaft head 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com