Tipping paper preventing liquid leakage, preparation method and application of same

A tipping paper and liquid technology, which is applied in the packaging of cigarettes, in the field of tipping paper, can solve the problems of loss of anti-seepage, anti-seepage, blocking, etc., so as to reduce suction resistance, facilitate use, and implement process performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

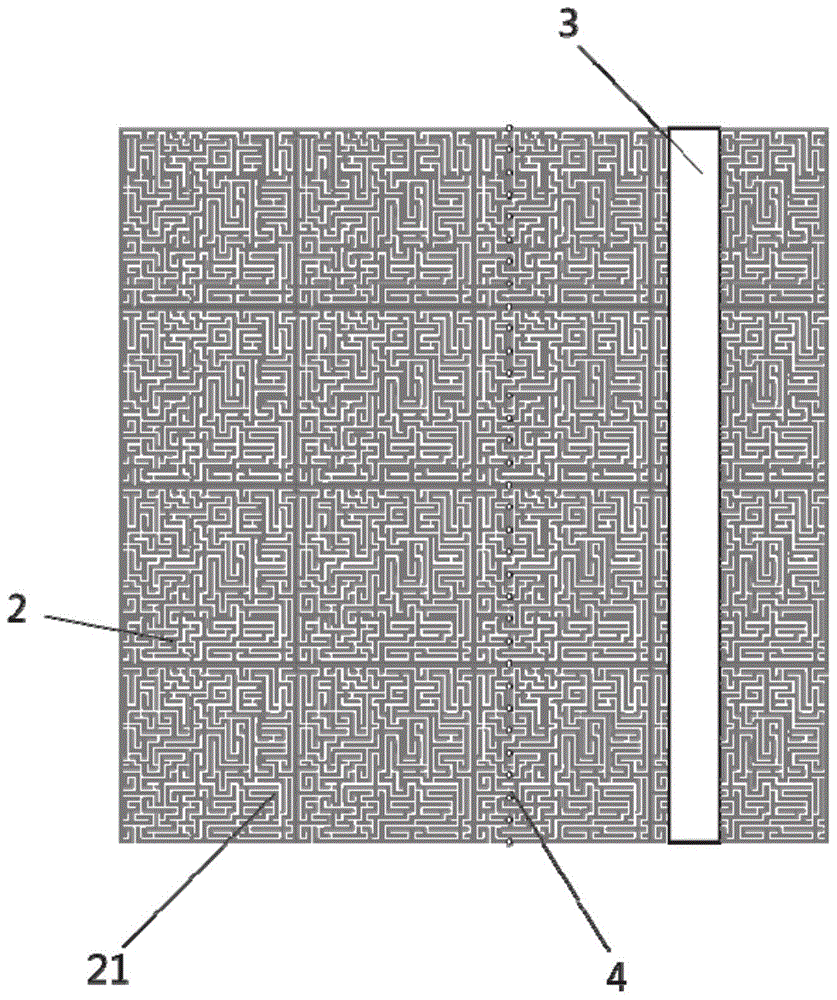

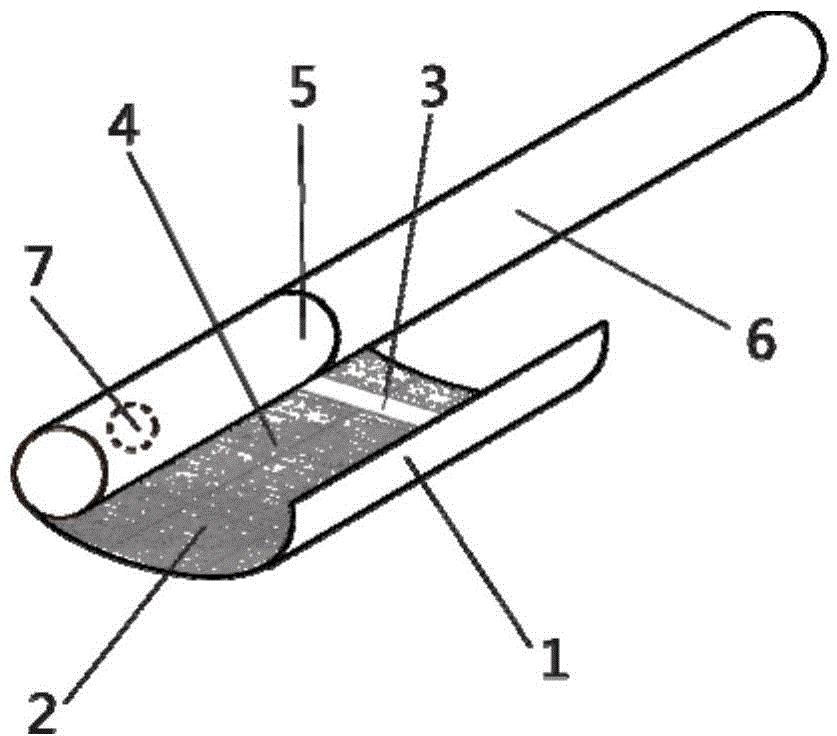

[0037] Such as figure 1 and 2 As shown, the tipping paper for preventing liquid leakage described in this embodiment includes a tipping paper base paper 1, and a layer of anti-seepage coating 2 is coated on the inner surface of the tipping paper base paper 1. The seepage coating 2 is a labyrinth anti-seepage structure formed by filling the resin with overlapping tiny scale-like hard foils 21; An axial anti-seepage strip 3, said axial anti-seepage strip 3 is an inverted trapezoidal long strip with a water-absorbing porous structure. In order to increase the proportion of outside air entering the filter rod to adjust the suction resistance, a row of small holes 4 are uniformly arranged at 2.5-3.0 mm from left to right on the tipping paper base paper 1 . The specific preparation steps of the tipping paper for preventing liquid leakage are:

[0038] (1) Ordinary tipping paper is used as the tipping paper base paper 1, and the resin filled with tiny scaly hard foils 21 is evenly...

Embodiment 2

[0043] Such as figure 1 and 2 As shown, the tipping paper for preventing liquid leakage described in this embodiment includes a tipping paper base paper 1, and a layer of anti-seepage coating 2 is coated on the inner surface of the tipping paper base paper 1. The seepage coating 2 is a labyrinth anti-seepage structure formed by filling the resin with overlapping tiny scale-like hard foils 21; An axial anti-seepage strip 3, said axial anti-seepage strip 3 is an inverted trapezoidal long strip with a water-absorbing porous structure. In order to increase the proportion of outside air entering the filter rod to adjust the suction resistance, a row of small holes 4 are uniformly arranged at 2.5-3.0 mm from left to right on the tipping paper base paper 1 . The specific preparation steps of the tipping paper for preventing liquid leakage are:

[0044] (1) Ordinary tipping paper is used as the tipping paper base paper 1, and the resin filled with tiny scaly hard foils 21 is evenly...

Embodiment 3

[0049] Such as figure 1 and 2As shown, the tipping paper for preventing liquid leakage described in this embodiment includes a tipping paper base paper 1, and a layer of anti-seepage coating 2 is coated on the inner surface of the tipping paper base paper 1. The seepage coating 2 is a labyrinth anti-seepage structure formed by filling the resin with overlapping tiny scale-like hard foils 21; An axial anti-seepage strip 3, said axial anti-seepage strip 3 is an inverted trapezoidal long strip with a water-absorbing porous structure. In order to increase the proportion of outside air entering the filter rod to adjust the suction resistance, a row of small holes 4 are uniformly arranged at 2.5-3.0 mm from left to right on the tipping paper base paper 1 . The specific preparation steps of the tipping paper for preventing liquid leakage are:

[0050] (1) Ordinary tipping paper is used as the tipping paper base paper 1, and the resin filled with tiny scaly hard foils 21 is evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com