Method for transforming shield tunneling system adapting to 36-degree pipe segments into shield tunneling system adapting to 22.5-degree pipe segments

A technology of propulsion system and segment, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problem of inapplicable 22.5° segment assembly, etc., and achieve the effect of shortening the transformation time, saving cost and reducing the total quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

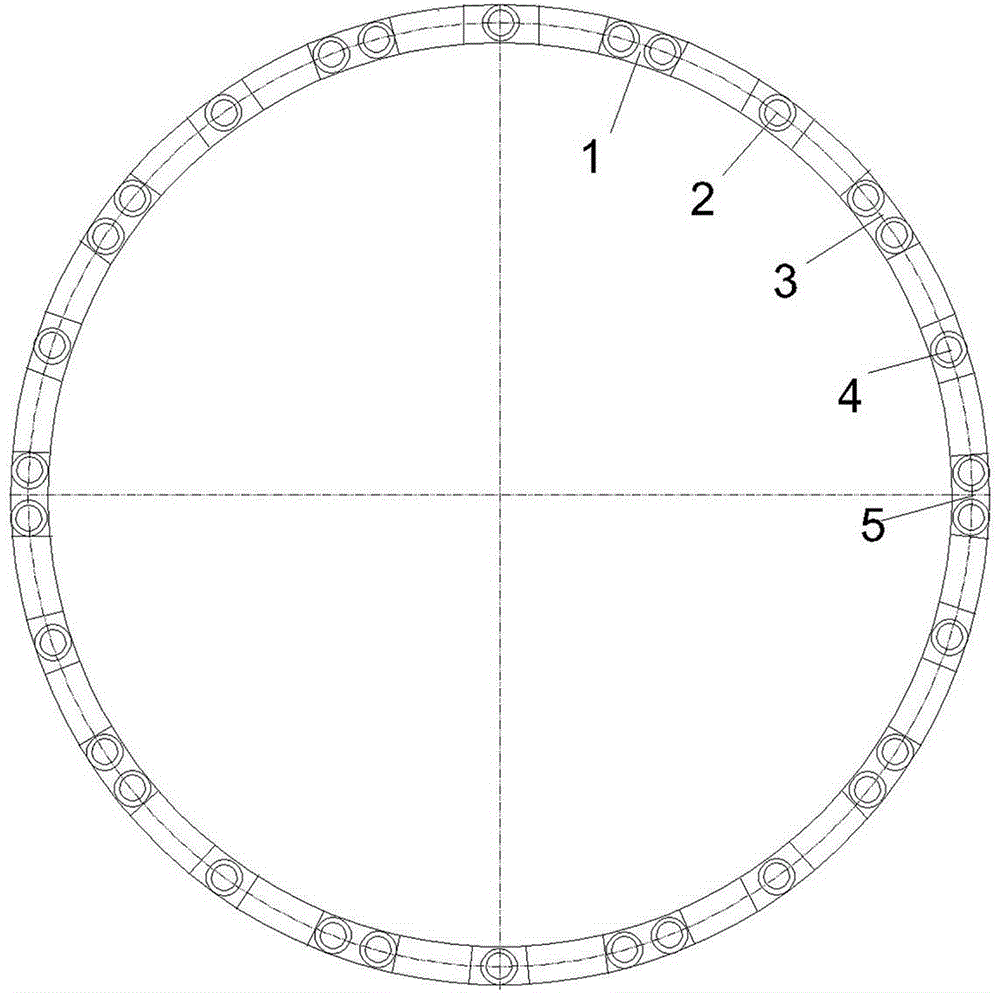

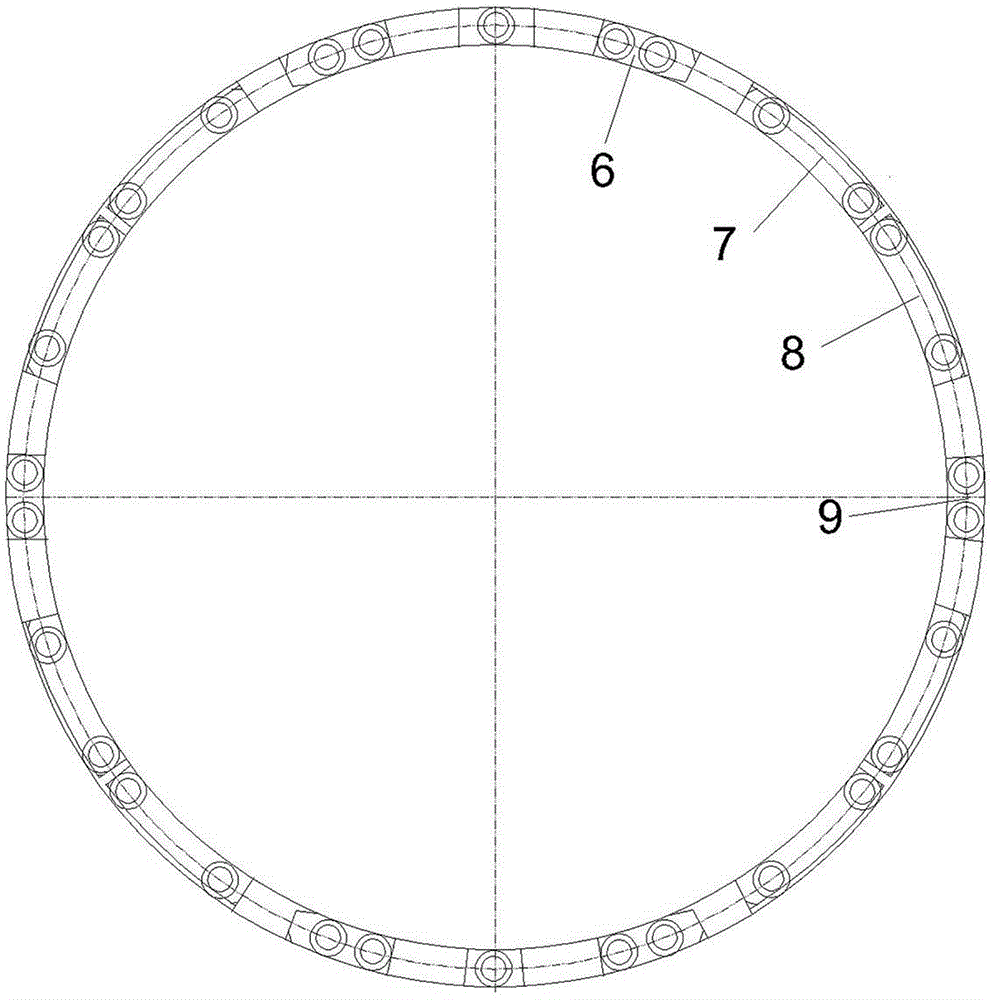

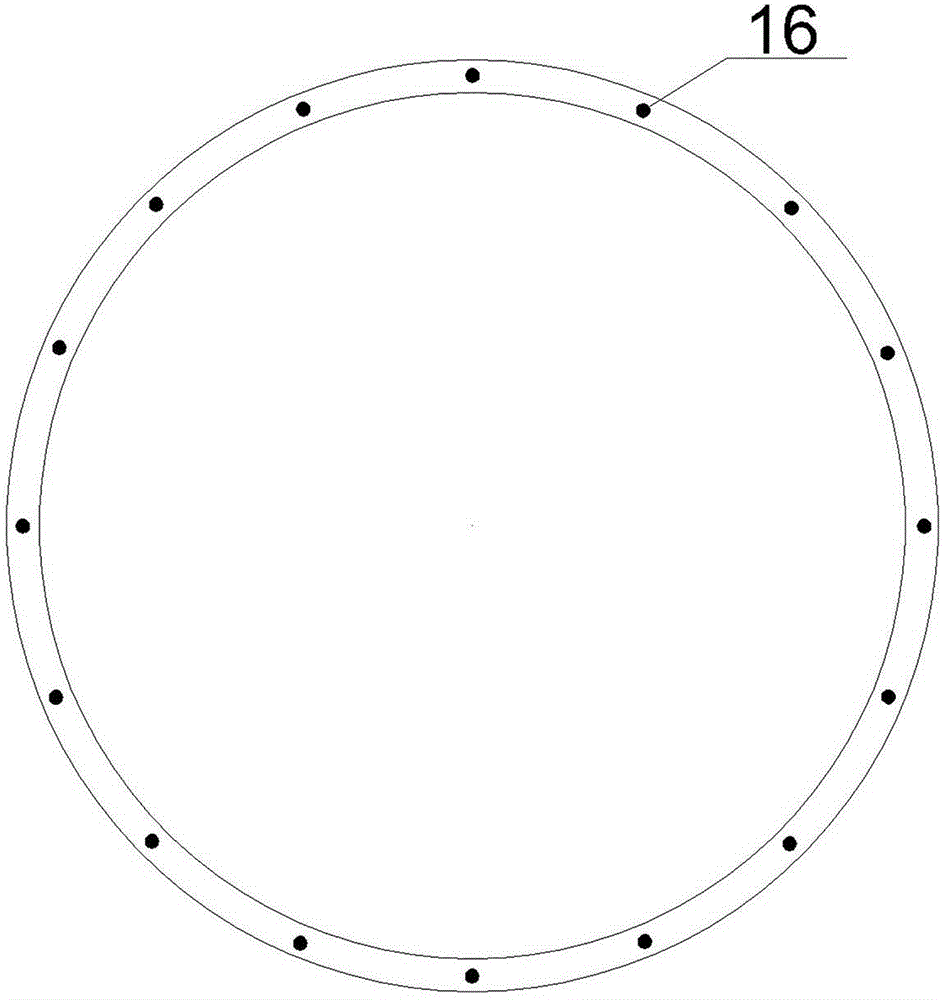

[0020] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 The present invention is described further:

[0021] The present invention provides a method for transforming the shield propulsion system adapted to 36° segments to adapt to 22.5° segments, and the original 30 single and double oil cylinders distributed at intervals of 18° are used for propulsion cylinders adapted to 36° segments. The layout is divided into four quadrants according to the two axes, including the first quadrant, the second quadrant, the third quadrant, and the fourth quadrant. The transformation of the first quadrant includes the following steps: welding the extension brace on the original No. 1 brace shoe 1 of the propulsion cylinder Boots 10 form the new No. 1 stretcher 6, and a new No. 1 boot plate 11 is installed on the new No. 1 stretcher 6, so that the pusher stretcher can satisfy the assembling of the capping block at a position of 22.5° above the deviat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com