A Cooling Structure of Centrifugal Water Pump Shaft Seal

A technology of centrifugal water pump and cooling structure, which is applied to parts, pumps, and pump elements of pumping devices used for elastic fluids. It can solve the problems of turning back heat and cannot be cooled, and achieve the effect of avoiding shaft seal damage and prolonging the service cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

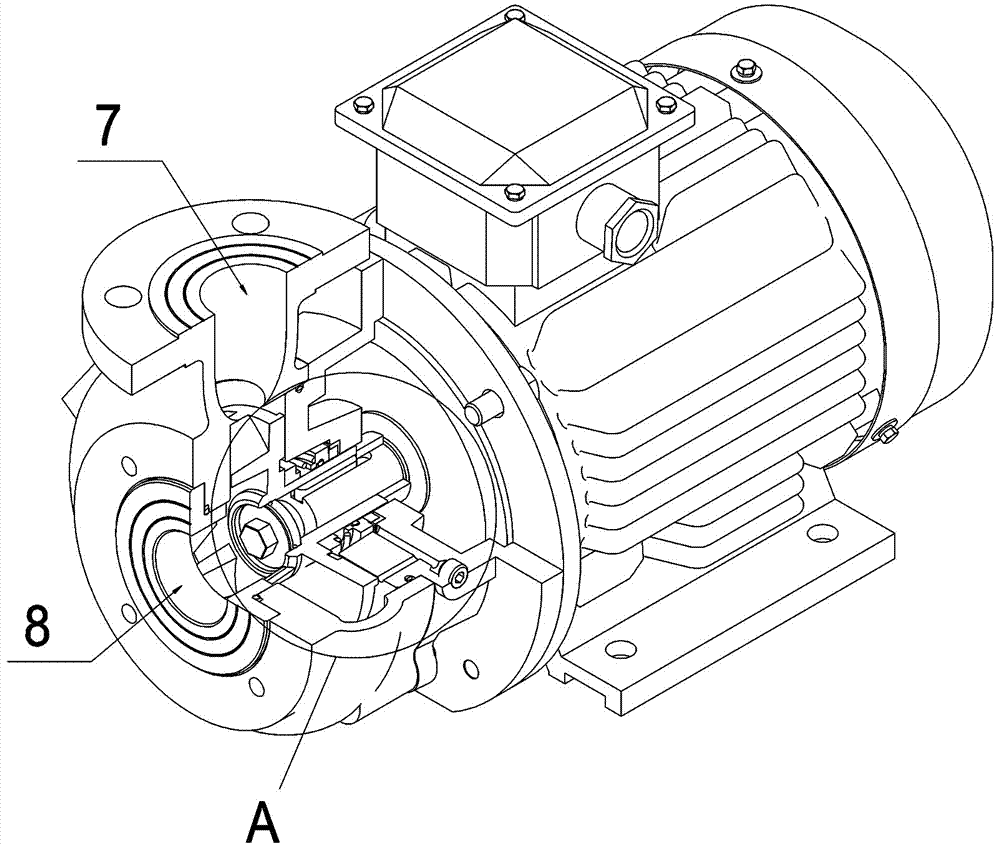

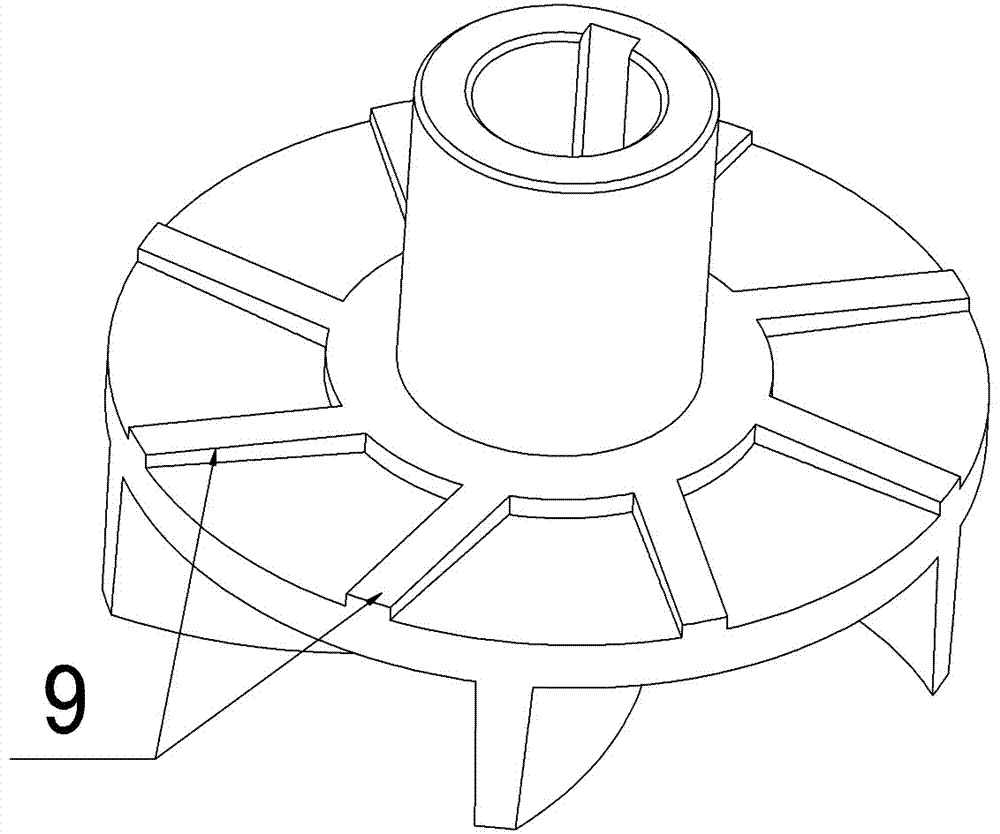

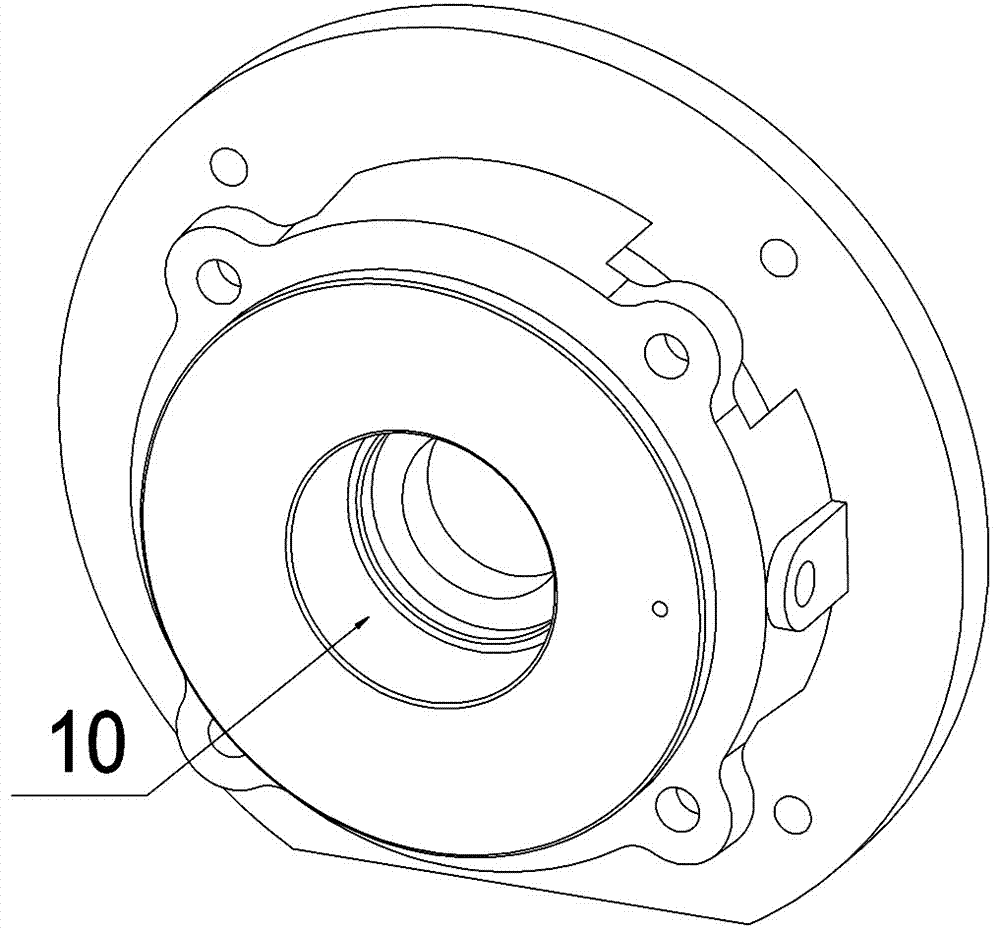

[0012] According to attached Figure 1~4 , the present invention is a cooling structure for a shaft seal of a centrifugal water pump. A flow channel 6 is arranged inside the shaft seal seat 4 of the centrifugal water pump. The flow channel 6 is composed of two mutually perpendicular and intersecting through holes, one of which is connected with The axis of the shaft seal seat 4 is parallel to the through hole on the outside of the shaft seal seat, and the other through hole is a radially arranged through hole perpendicular to the axis of the shaft seal seat 4. A sealing plug is set at the orifice, and the sealing plug is a spiral plug 5. The hole diameter of the flow channel 6 is 3 mm to 10 mm, and the inner wall of the orifice is provided with an internal thread matched with the thread of the helical plug 5 .

[0013] When the water pump is prefilled with water, the screw plug 5 is unscrewed earlier, and then the screw plug 5 is tightened again when a stream of water flows o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com