cable tie

A cable and master tape technology, applied in the direction of pipe supports, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problem of spending more manpower, and achieve the effect of simple structure, beautiful engineering, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A cable tie includes a cable tie mother belt and several cable tie sub-bands. Both the cable tie master strap and the cable tie sub-tie are cable ties made of nylon material.

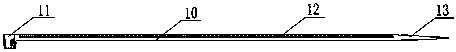

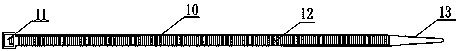

[0025] Such as figure 1 , figure 2 As shown, the cable tie master includes a master body 10, the first end of the master body 10 is fixedly provided with a master lock 11, and the master body 10 is provided with a master stop mechanism 12; the master body 10 The second end of the master tape is provided with a flat tip 13 .

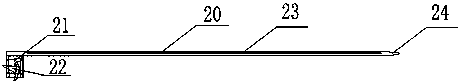

[0026] Such as image 3 , Figure 4 As shown, the cable tie sub-strap includes a sub-strap body 20, the first end of the sub-strap body 20 is provided with a sub-strap main lock 21, and the side of the sub-strap main lock 21 is fixedly provided with a sub-strap side lock 22. The main body 20 is provided with a sub-belt stop mechanism 23 , and the second end of the sub-belt body 20 is provided with a sub-belt flat tip 24 .

[0027] The sub-tape main locking opening 21 ...

Embodiment 2

[0032] A cable tie includes a cable tie mother belt and several cable tie sub-bands. Both the cable tie master strap and the cable tie sub-tie are cable ties made of nylon material.

[0033] Such as figure 1 , figure 2 As shown, the cable tie master includes a master body 10, the first end of the master body 10 is fixedly provided with a master lock 11, and the master body 10 is provided with a master stop mechanism 12; the master body 10 The second end of the master tape is provided with a flat tip 13 .

[0034] Such as image 3 , Figure 4 As shown, the cable tie sub-strap includes a sub-strap body 20, the first end of the sub-strap body 20 is provided with a sub-strap main lock 21, and the side of the sub-strap main lock 21 is fixedly provided with a sub-strap side lock 22. The main body 20 is provided with a sub-belt stop mechanism 23 , and the second end of the sub-belt body 20 is provided with a sub-belt flat tip 24 .

[0035] The side locking opening 22 of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com