Rapid fluid loading and unloading gun

A fast and fluid technology, applied in the direction of engine components, engine lubrication, lubricating parts, etc., can solve the problems of troublesome operation, low efficiency, uncleanness and hygiene, etc., and achieve the effect of convenient operation, high efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

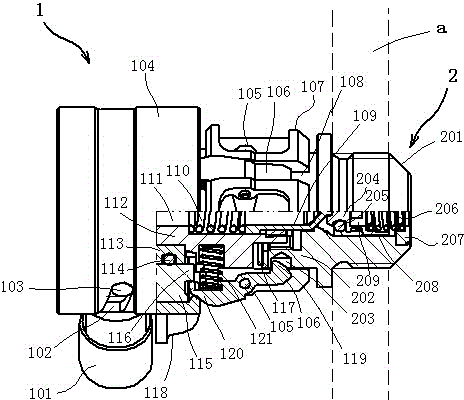

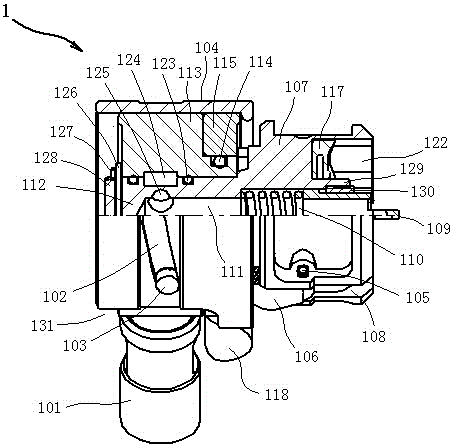

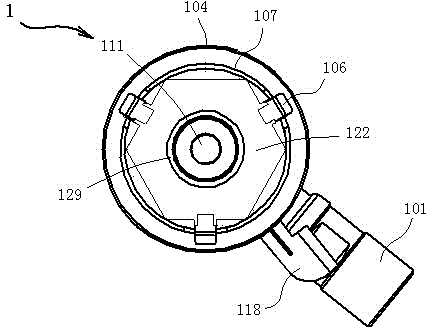

[0015] see figure 1 —3. The fluid quick release gun 1 provided by the present invention includes a chuck 107, and the rear portion of the chuck 107 is provided with a fixed shaft 112; A washer 117 is arranged in the groove 122, and several opening grooves 108 are uniformly arranged around the chuck 107, and a radially swinging claw 106 and a claw 106 rear portion 120 are hinged in each opening groove 108 by a pin 105. The return spring 121 that radially is arranged, the front end of claw 106 is provided with chuck 119, and the middle of chuck 107 is provided with fluid channel 111 to fixed shaft 112, and the front end 129 of fluid channel 111 protrudes forward in chuck 107 and A slot 122 is formed between the inner walls of the chuck, and the front end 129 of the fluid channel 111 in the chuck 107 is fixed with an outwardly protruding thimble 109 and a return spring 110 through a snap ring 130; on the fixed shaft 112 of the chuck 107 A sleeve 113, a first dial 115 and a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com