Ultrasonic three-dimensional detecting device for surface crack of concrete and detecting method thereof

A concrete surface, three-dimensional detection technology, applied to measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of small data collection, large detection errors, and large errors, and achieve large data collection and detection errors. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

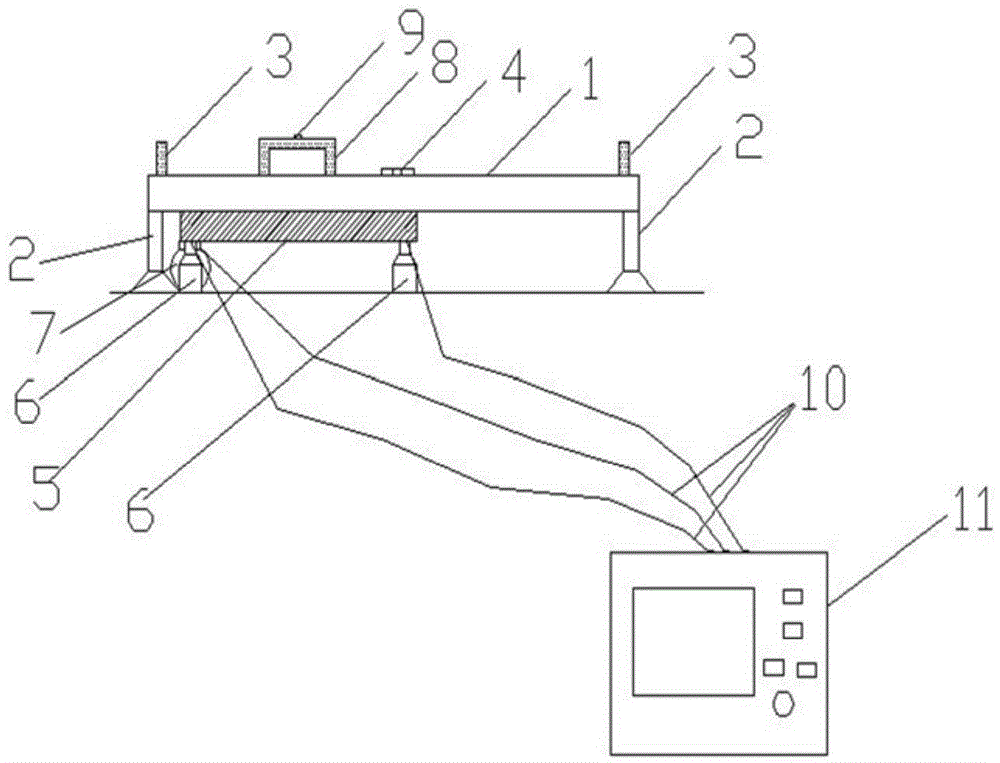

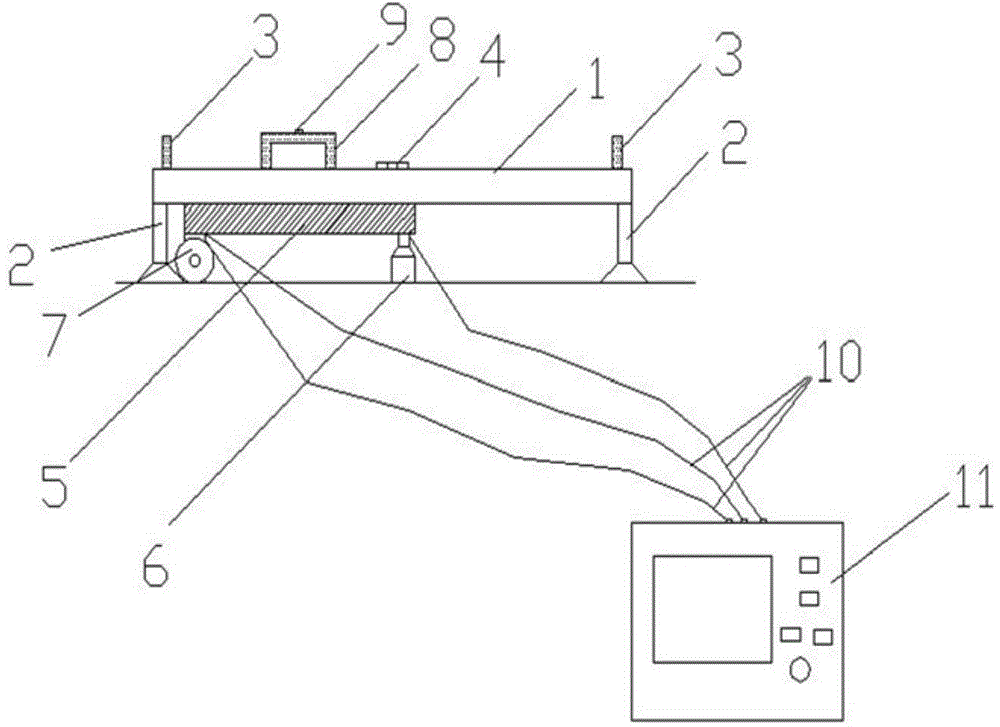

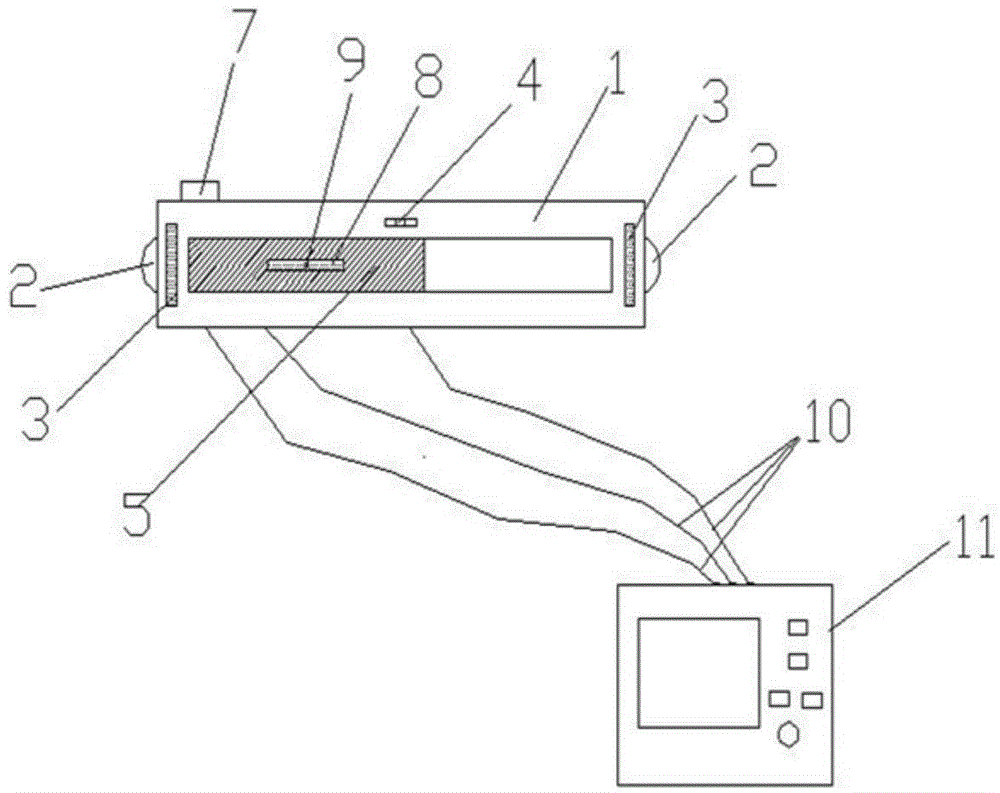

[0076] As shown in the figure, the three-dimensional positioning detection device for shallow cracks on the concrete surface of the present invention consists of a bracket 1, a bracket support foot 2, a fixed handrail 3, a level 4, a slider 5, an ultrasonic plane probe 6, a wheel encoder 7, a sliding Power-assisted armrest 8, slider center marking point 9, data transmission line 10, and ultrasonic instrument 11); its assembly relationship is: two support feet 2 are installed on the two ends of a rectangular support 1 made of a material with good wave resistance Below, two fixed handrails 3 are installed above the two ends of the support 1, a level 4 is installed above the middle point of the support 1, a rectangular slider 5 is installed in the middle chute below the support 1, and two ultrasonic plane probes 6 Placed below the two ends of the rectangular slider 5, a wheel encoder 7 is placed on one side of the rectangular slider 5, one end of the three data transmission lines ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com