Existing concrete continuous core taking apparatus

A coring device and concrete technology, which is applied in the direction of sampling devices, etc., can solve the problems of slow coring speed, high labor intensity of workers, and inability to perform continuous coring operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

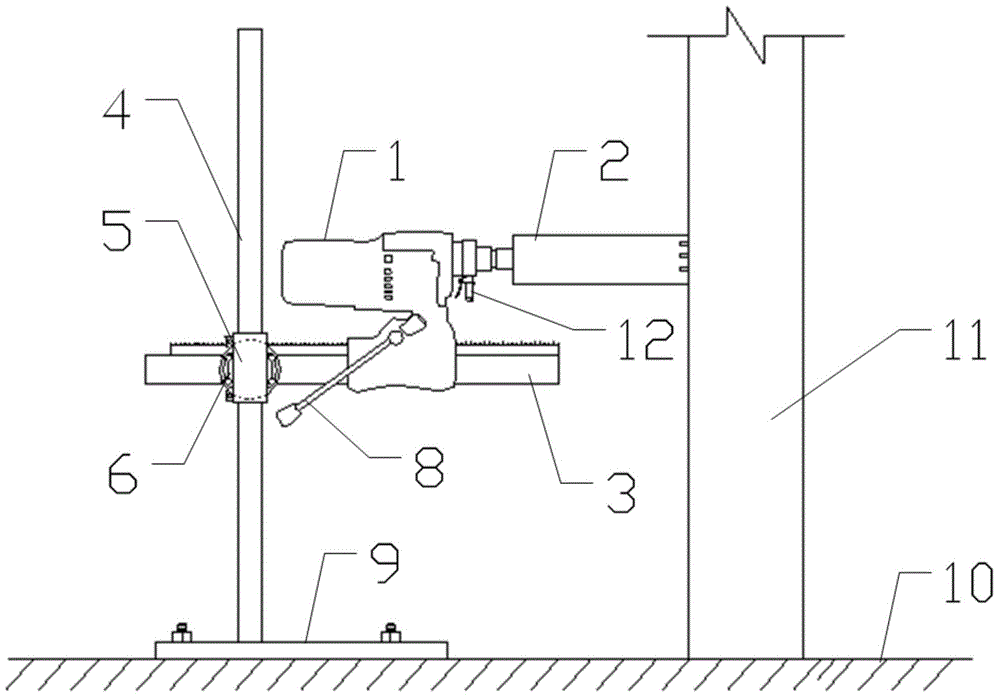

[0025] The present invention will be further described below in conjunction with accompanying drawing.

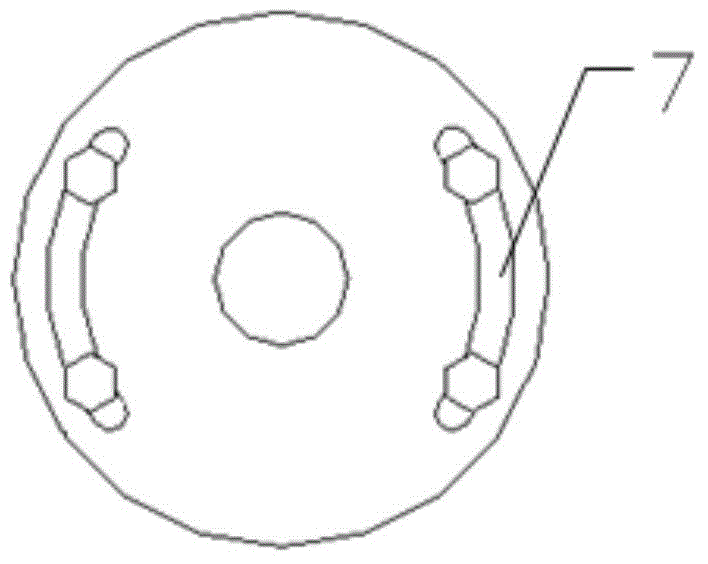

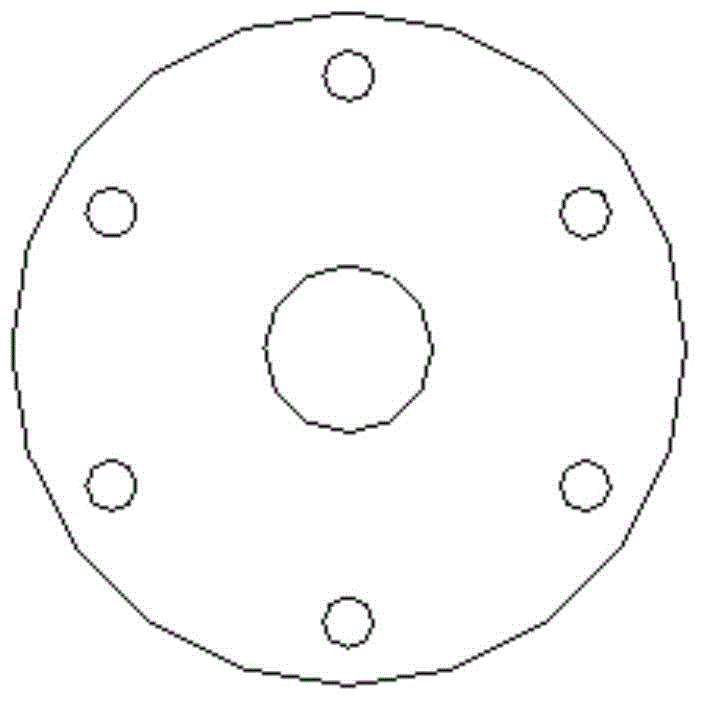

[0026] Such as Figure 1 to Figure 4 As shown, a kind of old concrete coring device that can be continuously taken out, comprises concrete coring machine 1, support, height adjustment sleeve 5, and the head of described concrete coring machine 1 is equipped with coring bit 2, and described concrete The body of the coring machine 1 is equipped with a rack guide rail 3, the support includes a column 4, the height adjustment sleeve 5 is fixedly connected with the column 4 through an adjustment bolt, and the height adjustment sleeve 5 is connected to the rack guide rail 3. Fixed connection at one end. By fixedly connecting the rack guide rail 3 with the height adjustment sleeve 5, the height and direction of coring can be adjusted by adjusting the height of the gear guide rail 3, so that the height of the concrete coring machine 1 can be quickly adjusted according to the situa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com