3-DOF (degree of freedom) mobile loading platform for vertical optical microscope

An optical microscope and object stage technology, applied in microscopes, optics, optical components, etc., can solve problems such as poor imaging effect, achieve poor resolution, large observation area, and overcome limited distance or precision when focusing on the lens barrel. limited effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

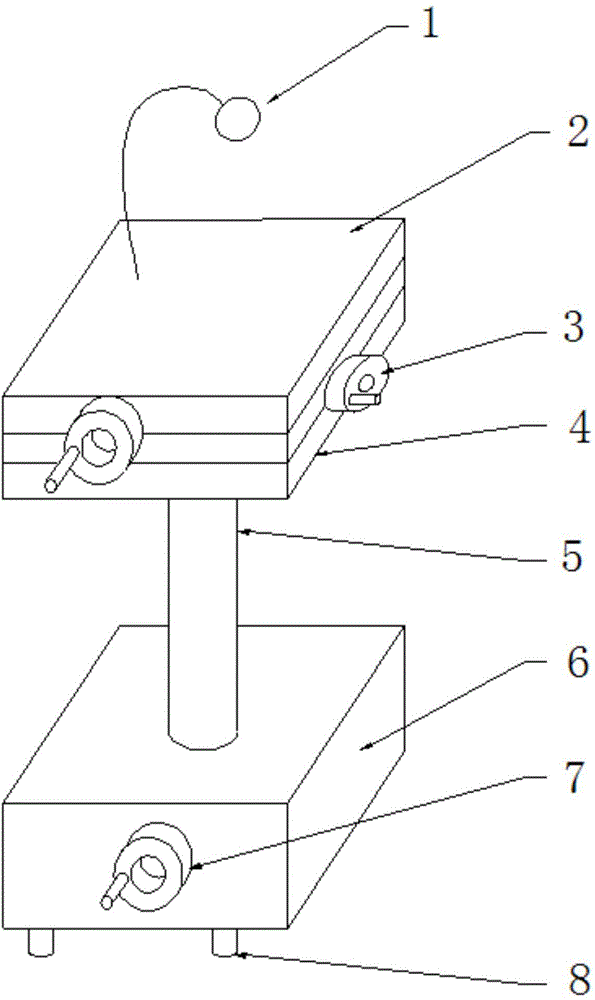

[0020] A three-degree-of-freedom mobile loading platform for a vertical optical microscope, including a light source 1, a horizontal position adjustment platform, a rising rod 5, a base 6, and a vertical displacement adjustment handle 7; the light source 1 is arranged on the horizontal position adjustment platform, and the lifting One end of the rod 5 is fixed to the horizontal position adjustment platform, and the other end extends into the base 6. The base 6 is provided with a displacement adjustment handle 7 that drives the rising rod 5 to move in the base 6 along the vertical direction. The horizontal position adjustment platform includes two horizontal displacement Guide block 2, two horizontal displacement adjustment handles 3, and a base 4, two horizontal displacement guide blocks 2 are arranged on the base 4 along the vertical direction, and the sides of the horizontal position adjustment platform are respectively provided with horizontal plates that drive the upper laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com