Transformer provided with guide sliding blocks and driven by chain

A technology of guide slider and chain transmission, which is applied in the field of transformers, can solve the problems of inconvenient maintenance and achieve the effect of large power transmission and stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

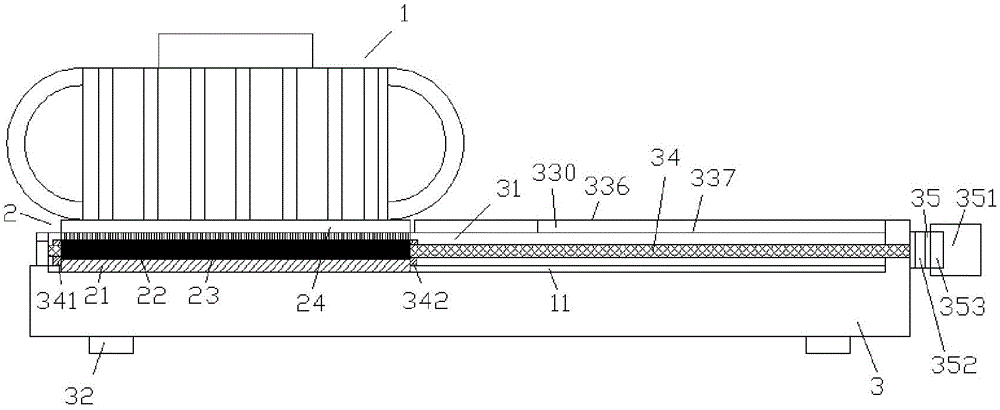

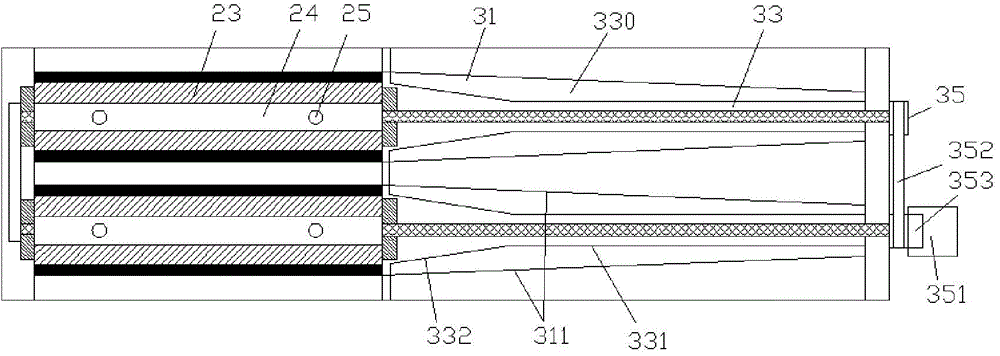

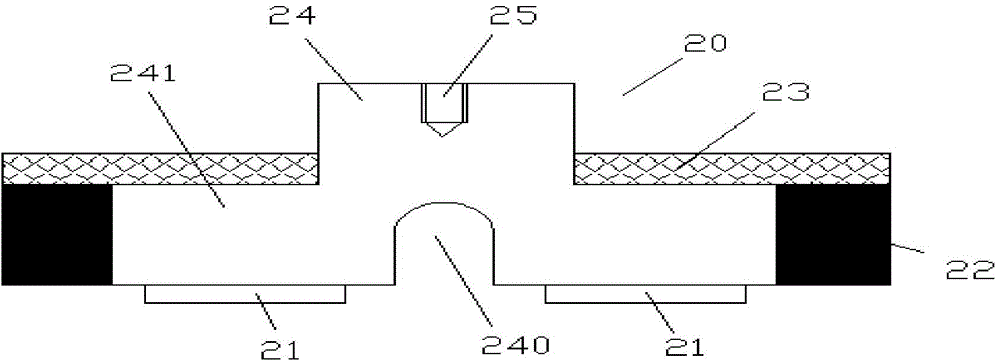

[0010] Below by combining Figure 1-3 , the present invention is described in detail through specific examples.

[0011] Through the above methods, those skilled in the art can make various changes according to the working modes within the scope of the present invention.

[0012] According to an embodiment, a transformer with a guide slider and chain transmission includes a body 1 including an iron core coil assembly and lead wires (not shown), a body base 2, and a mounting frame 3, wherein, for the sake of brevity, The specific parts of the transformer body 1 are not described, which are known means in the art or these known means can be used; the bottom side of the installation frame 3 is used for fixed connection with the transformer body, and the device The body base 2 is fixedly connected to the bottom of the body 1, and includes at least two base bars 20, each base bar 20 has an upper protruding joint 24 and below the protruding joint 24 and A width extension 241 exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com