Prefabricated slab component mechanical property detection system

A detection system and prefabricated panel technology, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, scientific instruments, etc., can solve problems such as failure to meet the detection requirements of reinforced concrete prefabricated components, hidden safety hazards, and slow speed. Achieve the effect of strong mechanism strength, guarantee accuracy, and improve structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

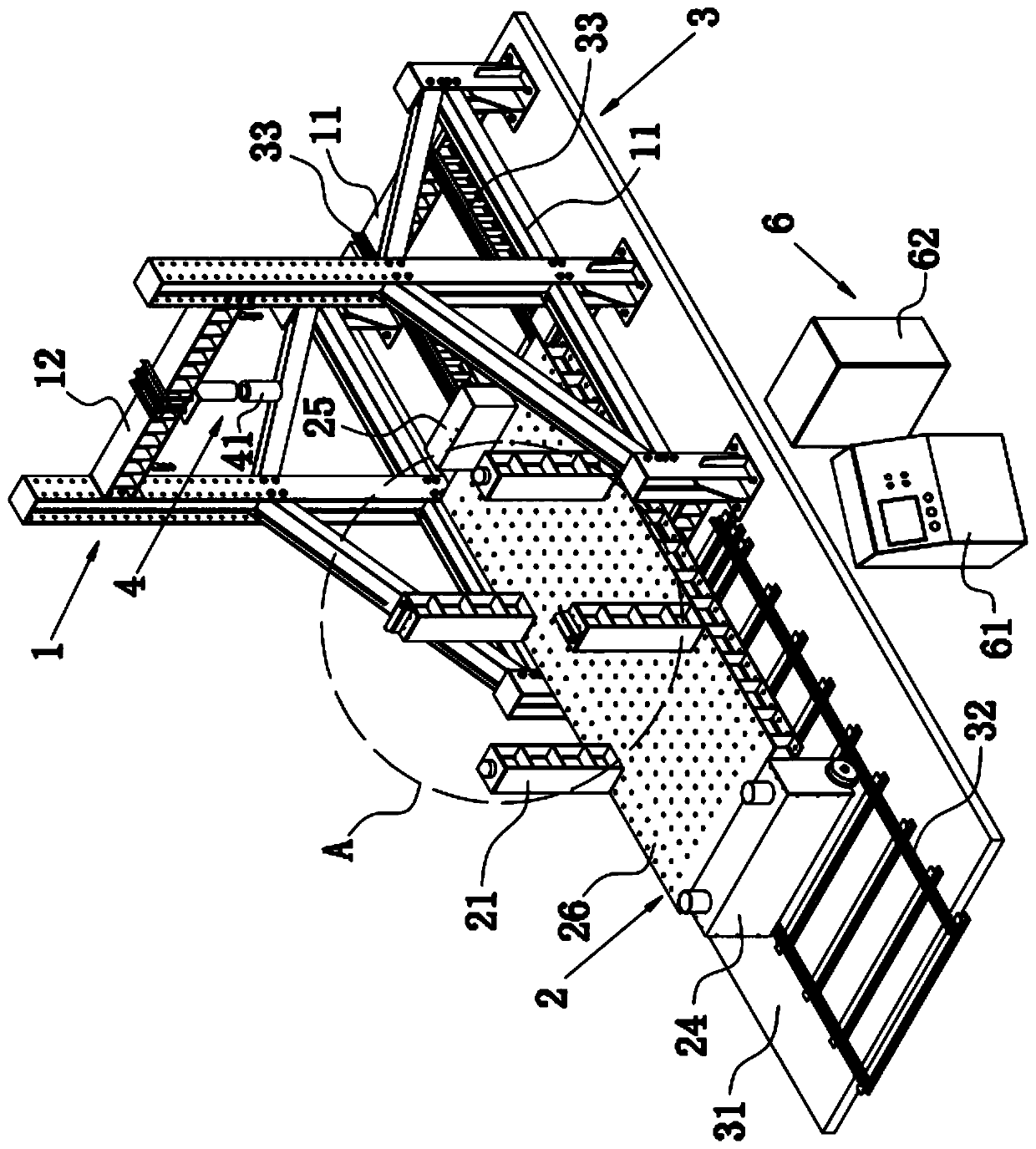

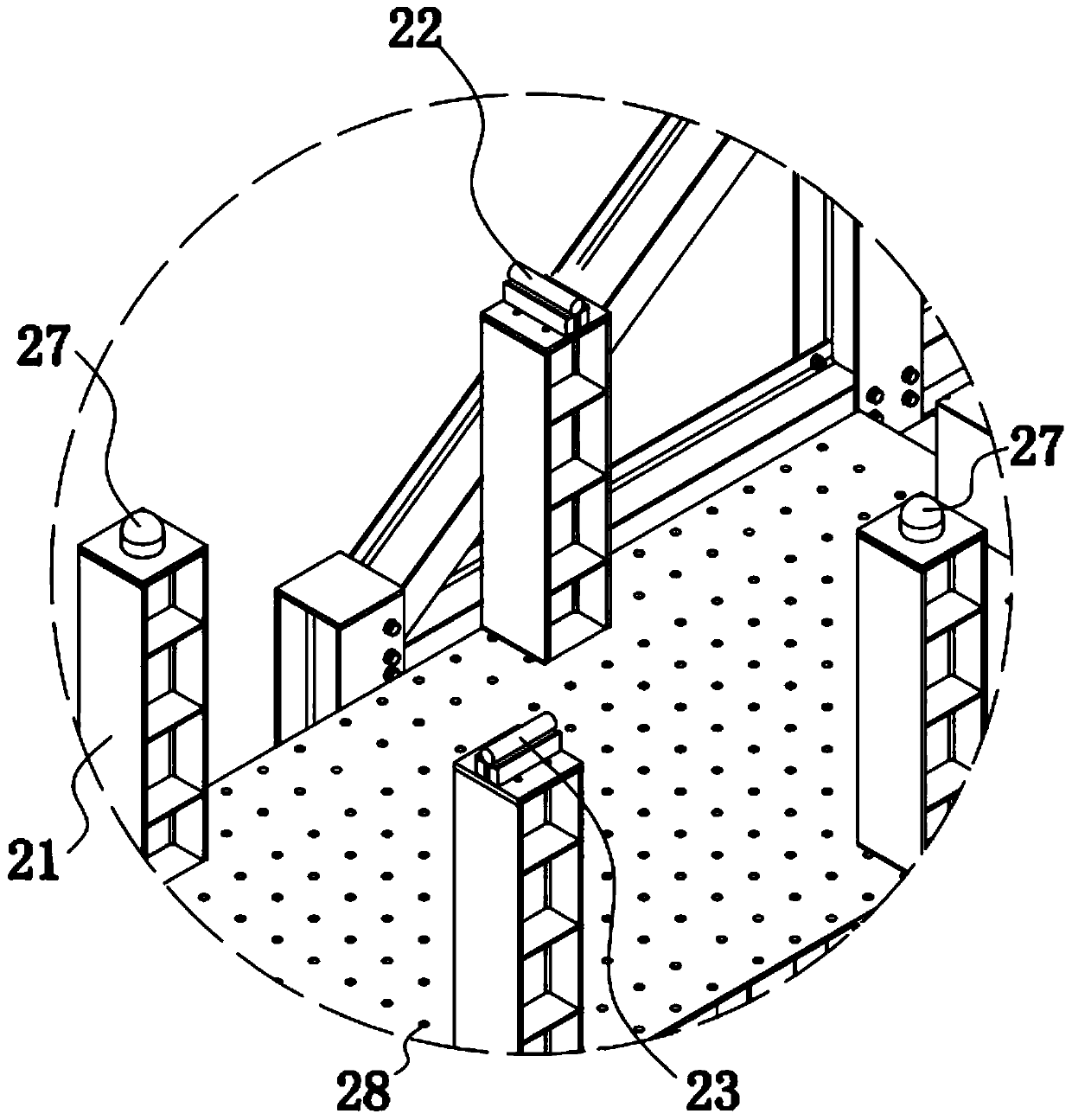

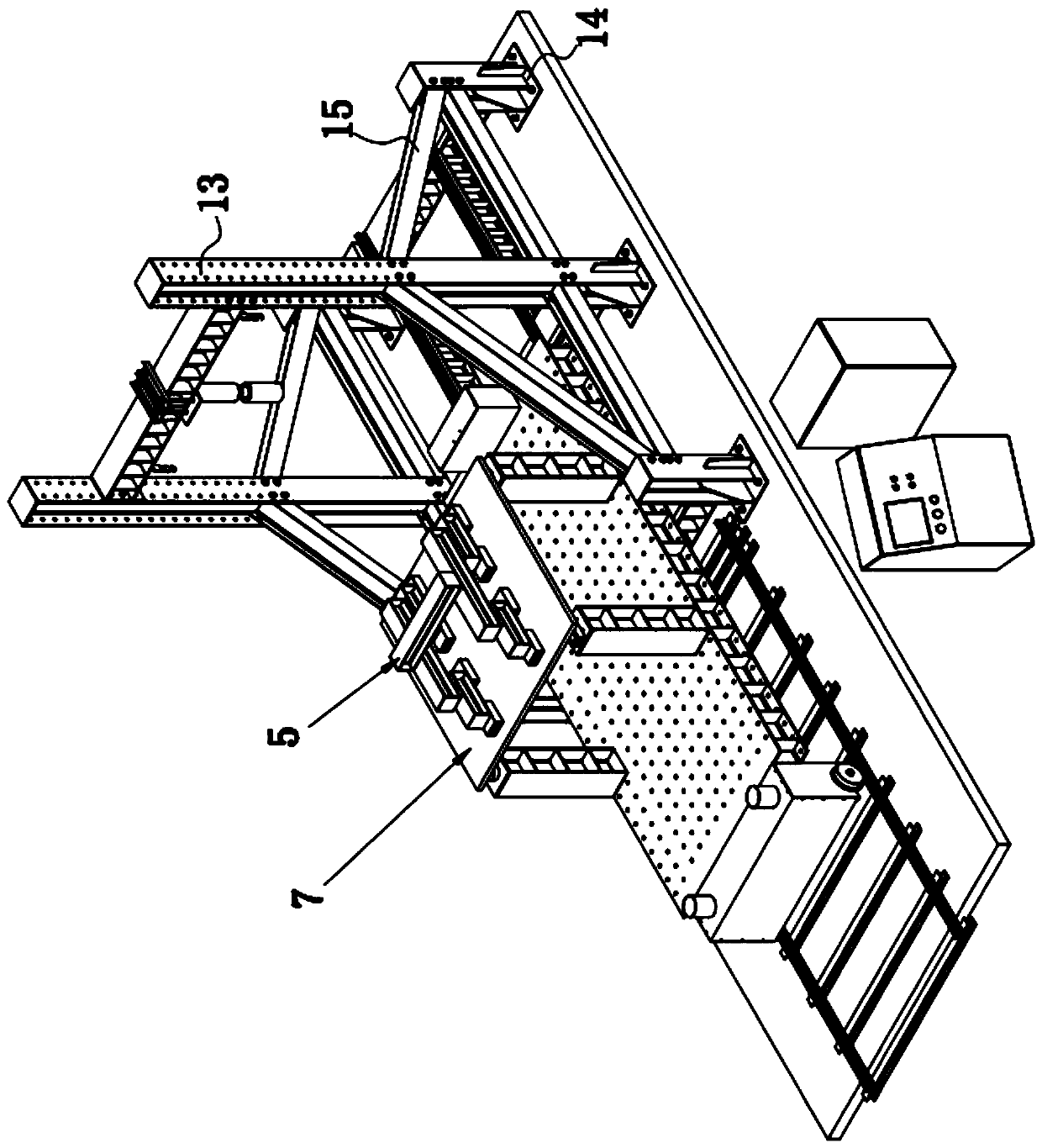

[0037]In order to achieve the purpose of the present invention, a prefabricated plate member mechanical performance testing system includes: a press-down mechanism, which applies hydraulic pressure to the rectangular plate member 7 to apply a vertical downward pressure; a translation load-bearing mechanism, located below the press-down mechanism It has a horizontal translation degree of freedom that moves out from directly under the pressing mechanism; the translational load-bearing mechanism also has a roller support and a hemispherical support 27 that are in contact with the lower surface of the plate member 7, and the roller support and the plate member 7 form a line contact. The bearing 27 forms a point contact with the plate member 7, and the roller bearing includes a first roller bearing 22 and a second roller bearing 23. The first roller bearing 22 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com