Hot stamping machine

A technology of hot embossing equipment and embossing equipment, which is applied in the direction of metal processing equipment, printing, printing machines, etc., which can solve the problems of enlarging, manual cleaning and stripping edges of hot embossing equipment, and achieve the effect of avoiding overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

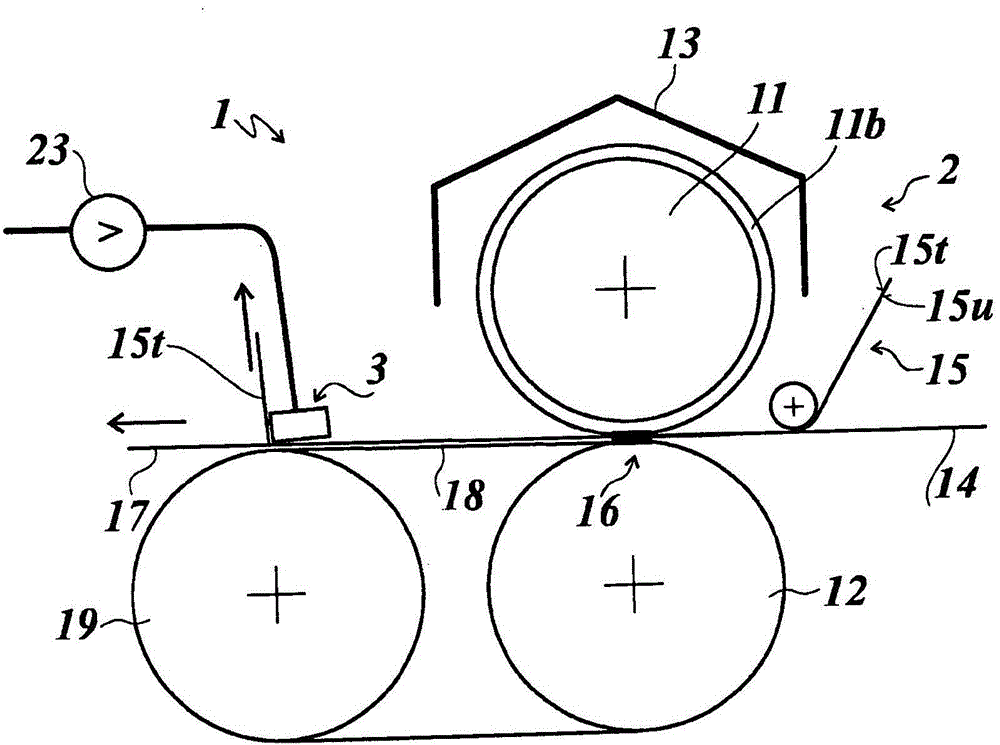

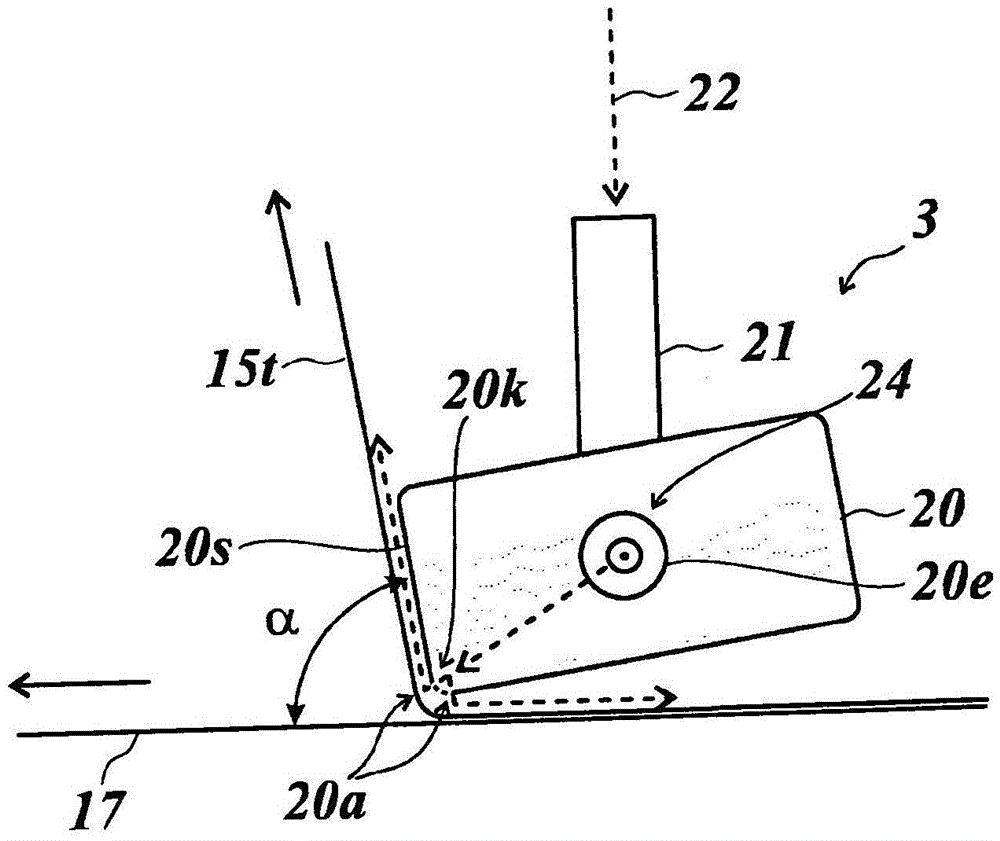

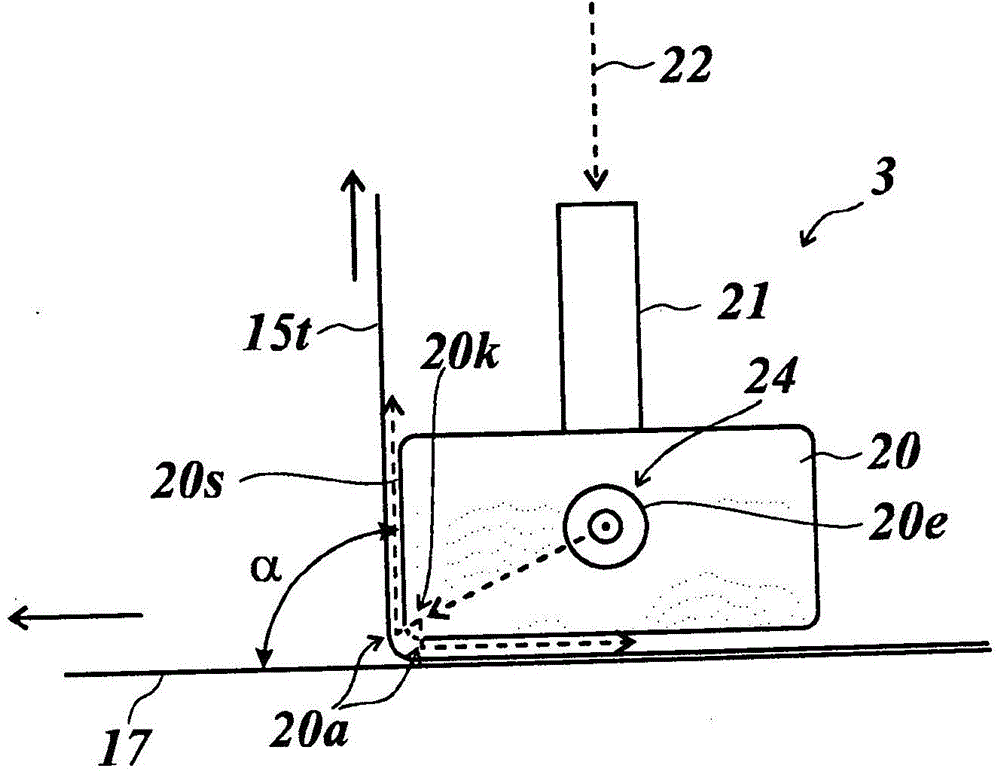

[0033] figure 1 A thermal embossing device 1 is shown, which has an embossing device 2 and a stripping device 3 . The embossing apparatus 2 includes an embossing roller 11 , a counter-pressing roller 12 and a heating device 13 .

[0034] The embossing roller 11 has a coating 11b made of an elastomer on its outer circumference. The elastomer is preferably silicone rubber. The counter pressure roller 12 is made of steel.

[0035] The heating device 13 is arranged above the embossing roller 11 and figure 1 In the exemplary embodiment shown, it is designed as an infrared radiation heating device controlled by means of a temperature controller.

[0036] Upstream of the embossing device 2 , the substrate 14 to be embossed and the hot embossed film 15 are fed, said substrate and said hot embossed film being formed in the embossing nip formed between the embossing roller 11 and the counter-embossing roller 12 16 are connected to each other under the condition of forming embossing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com