Reactant flow channels for electrolyzer applications

A technology of electrolyzer and channel, applied in the field of electrolyzer, can solve the problem of limiting the rate of electrochemical oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

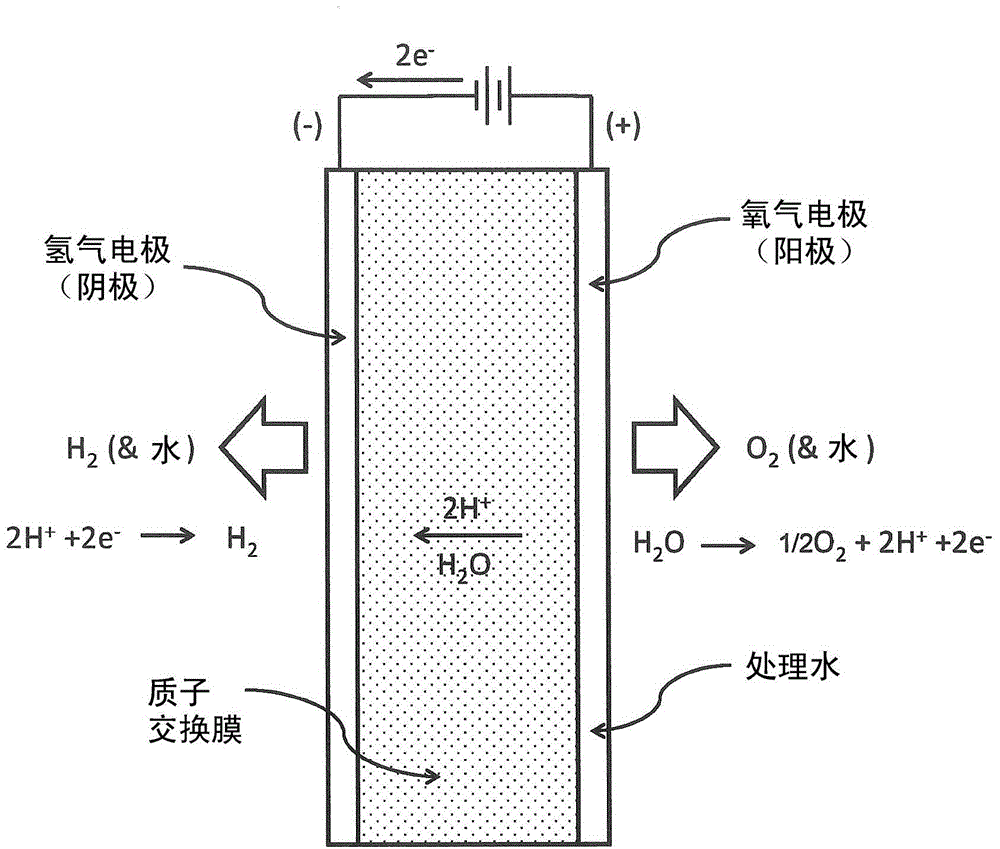

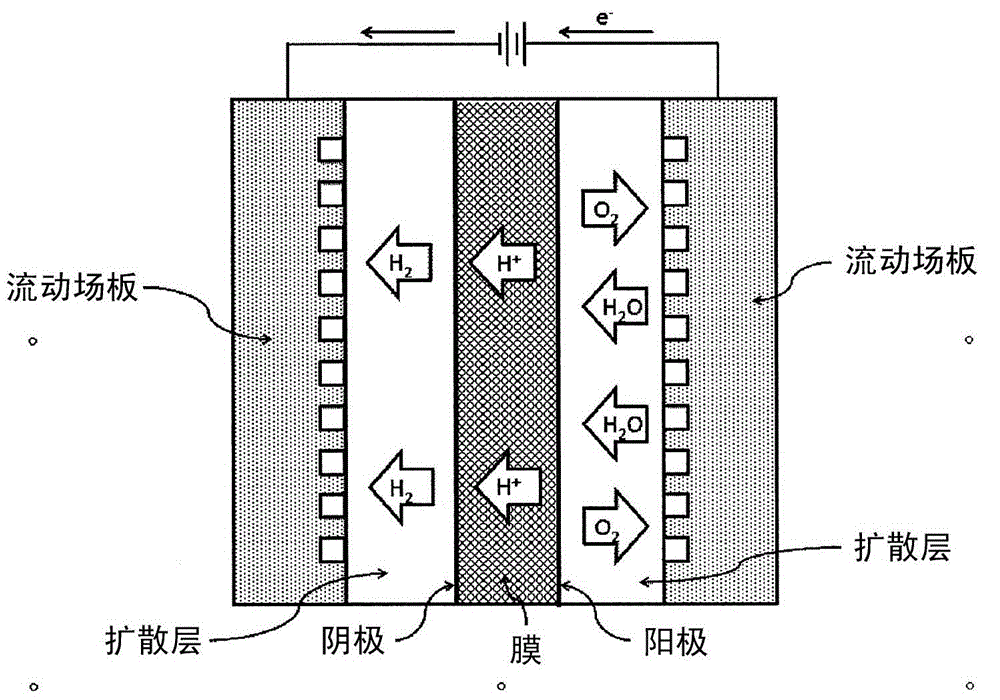

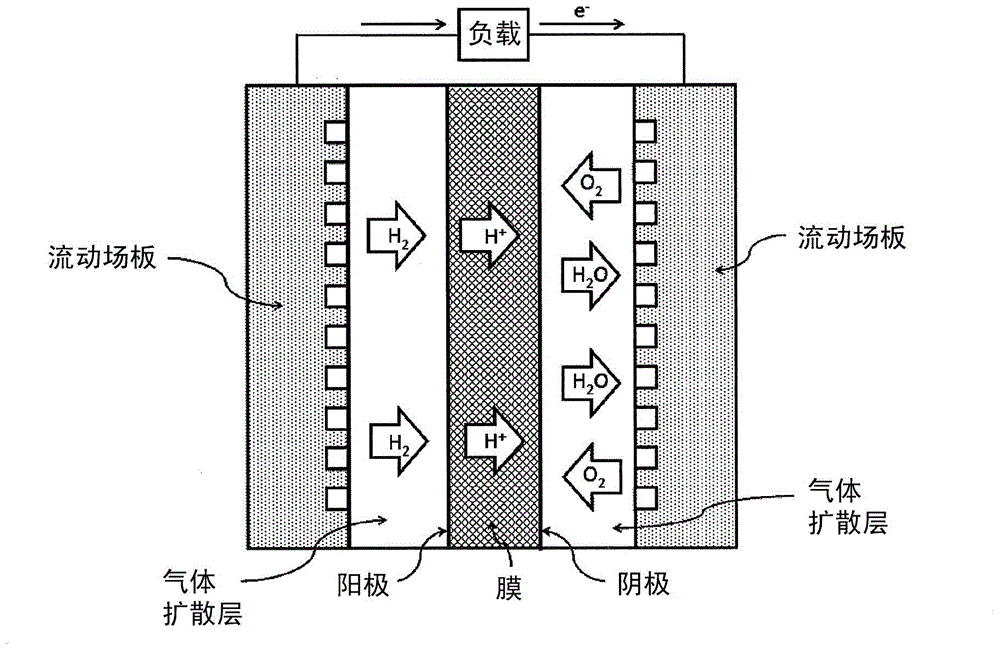

[0055] The electrolyzer assembly includes a flow field plate including at least one channel, wherein the cross-sectional area of the channel varies along at least a portion of the length of the channel. In a preferred embodiment, the channel width decreases according to a natural exponential function in the direction of reactant flow along at least a portion of the channel length. The use of this type of improved flow field channel, in particular at the oxygen electrode (electrolyzer anode) can improve the performance and / or efficiency of the operation of the electrolyzer assembly.

[0056] Without being bound by theory, the following discussion, equations, and mathematical models may help explain at least some of the basis for the various advantages that may be realized using the embodiments of the invention described herein.

[0057] One approach is to design the electrolyzer anode flow channel for a substantially constant water velocity such that the electrolyzer anode fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com