Mushroom culture material bagging machine

A material bagging machine and mushroom technology, which is applied in the field of automatic bagging devices for mushroom culture materials, can solve the problems of low work efficiency, difficulty in large-scale production, and inability to realize automatic bag opening operations, and improve the charging efficiency. , the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

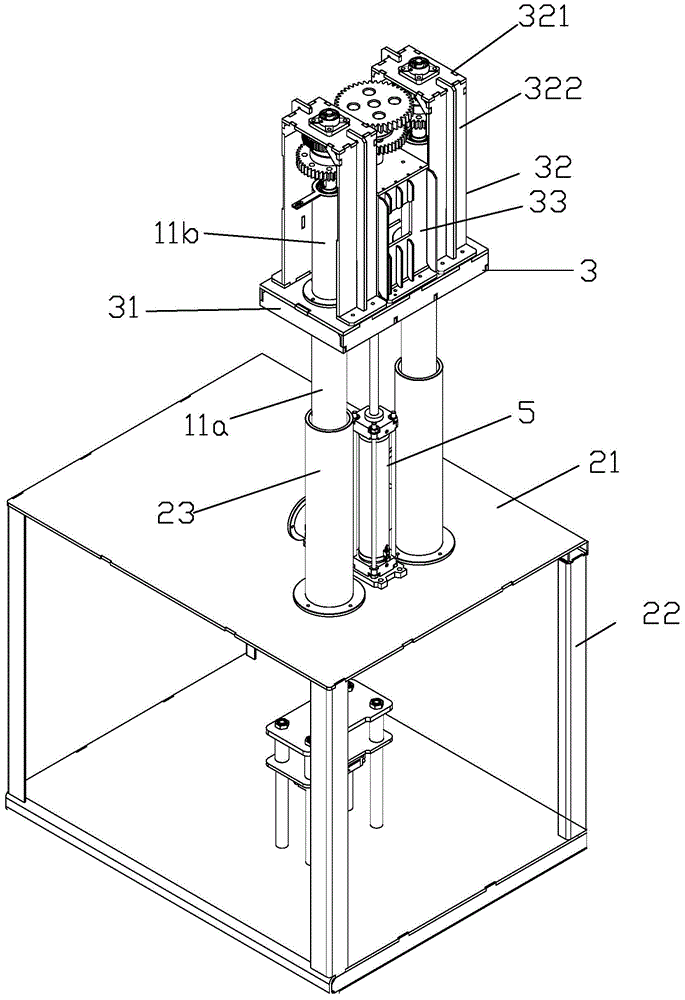

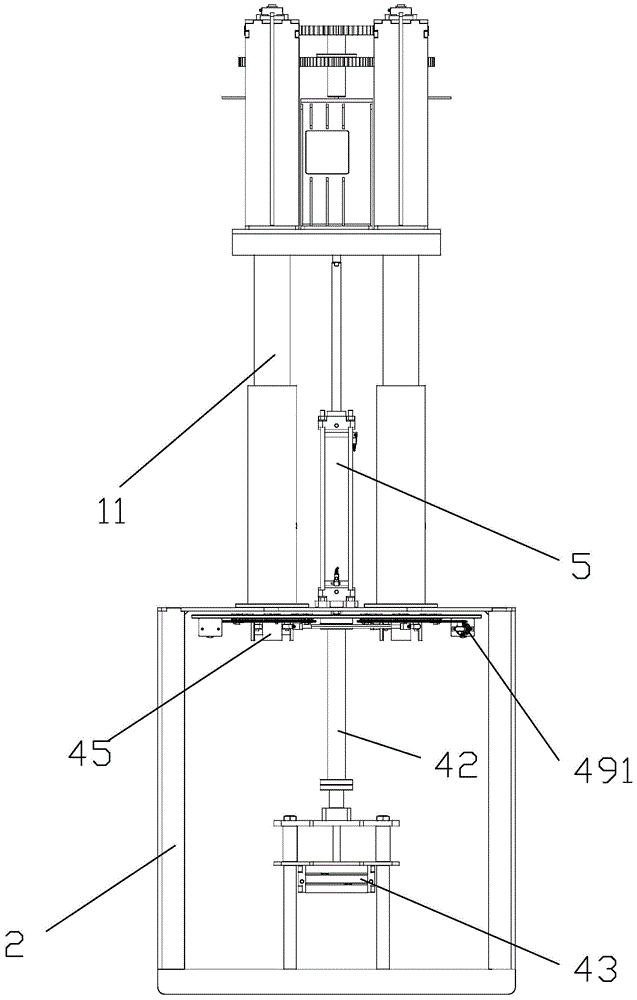

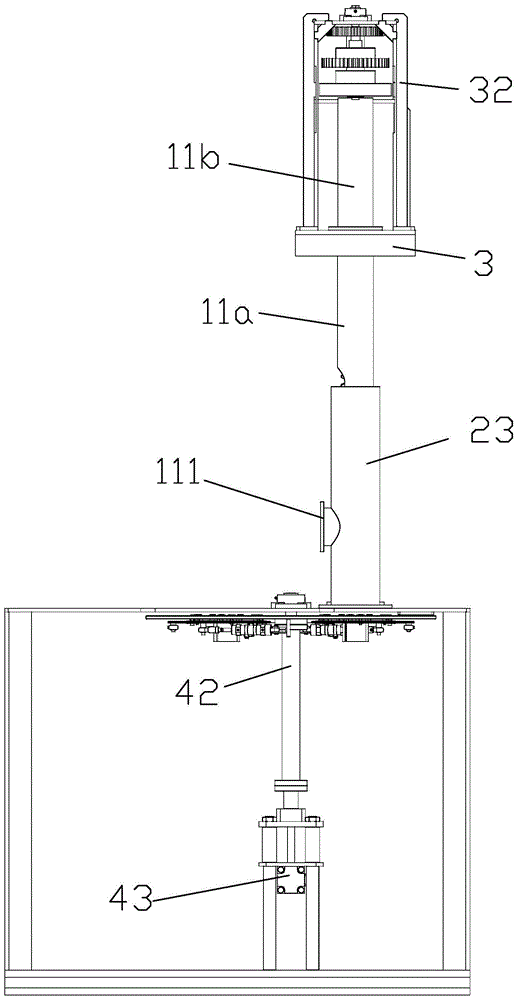

[0026] See Figure 1 to Figure 5 . According to an embodiment of the present invention, the mushroom culture material bagging machine includes two sets of screw conveying mechanisms vertically arranged side by side, a machine base 2, a bracket 3, a bag opening mechanism, and a mechanism for driving the two sets of screw conveying mechanisms to rise and fall. lift drive mechanism.

[0027] Each set of screw conveying mechanisms includes a housing 11, a screw shaft 13, a screw shaft drive mechanism for driving the screw shaft to rotate, a pressing rod 17 and a pressing rod driving mechanism for driving the pressing rod to rotate. A helical blade 14 is provided on the side wall of the helical shaft 13 . Each group of screw conveying mechanisms is vertically arranged, and the side of the housing 11 of each group of screw conveying mechanisms is provided with a feed port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com