A kind of heterojunction ternary composite semiconductor photocatalyst and preparation method thereof

A ternary composite and photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve a wide range of problems, and achieve simple and good preparation process The effect of dye degradation ability and good universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

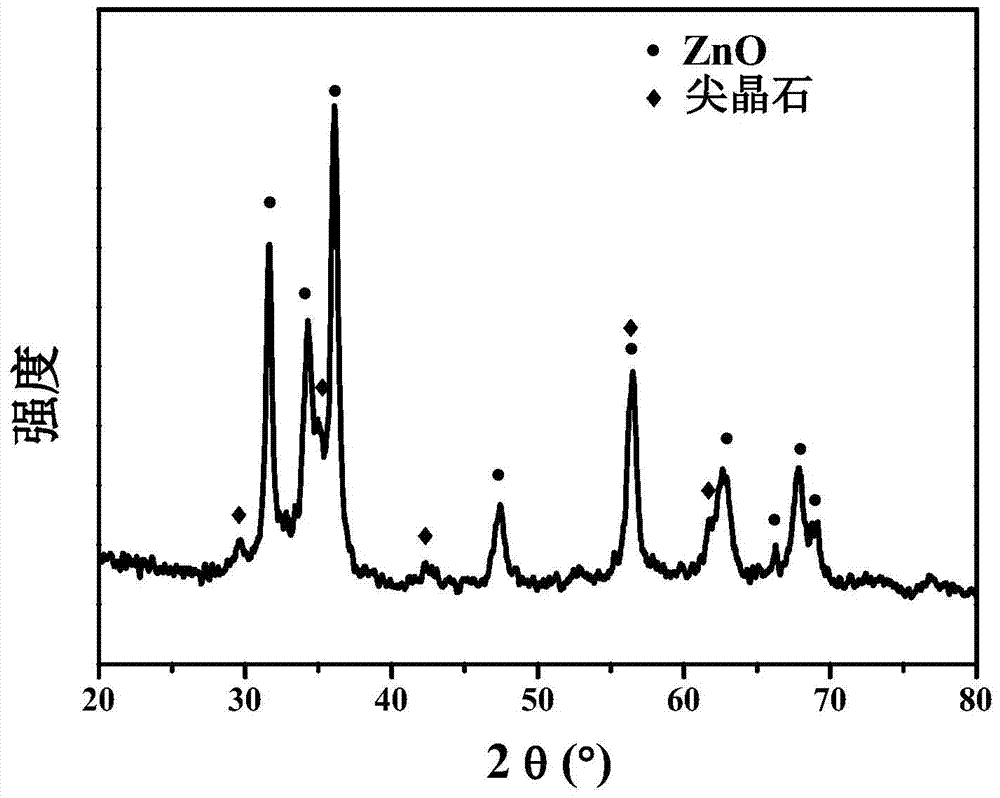

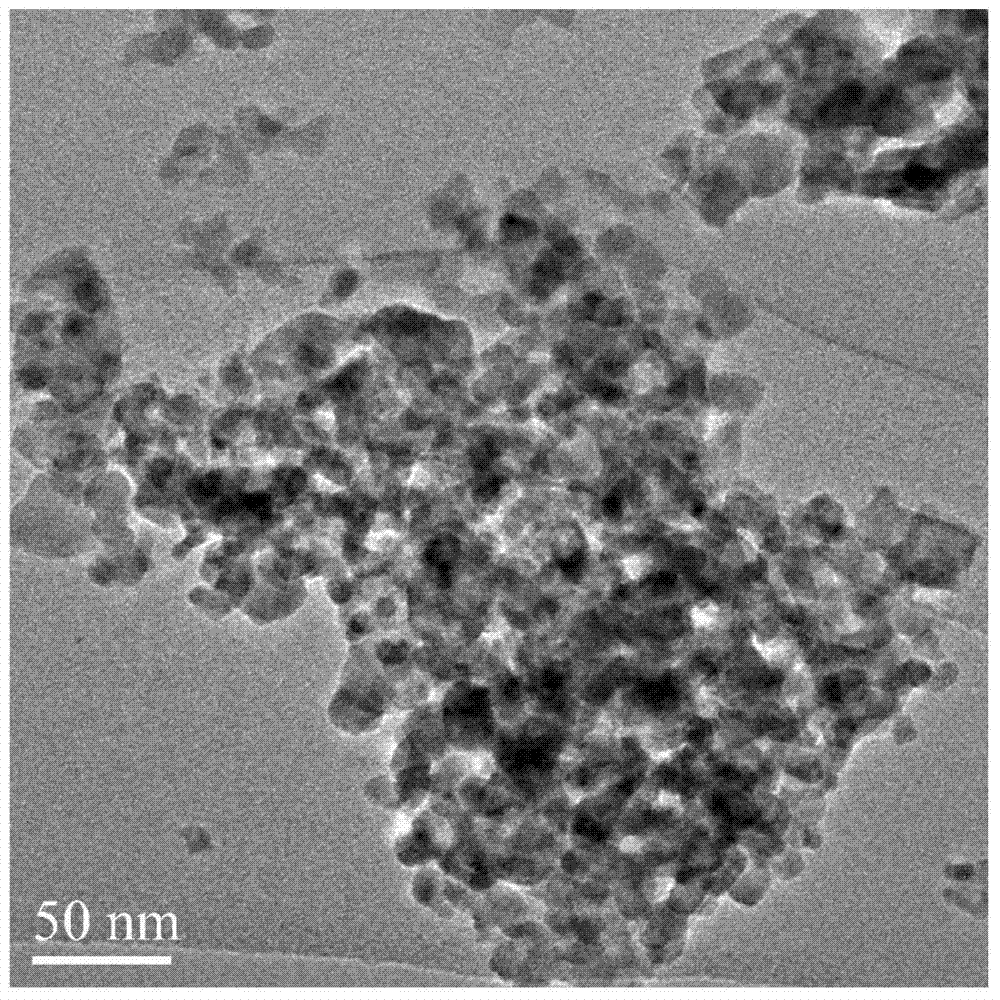

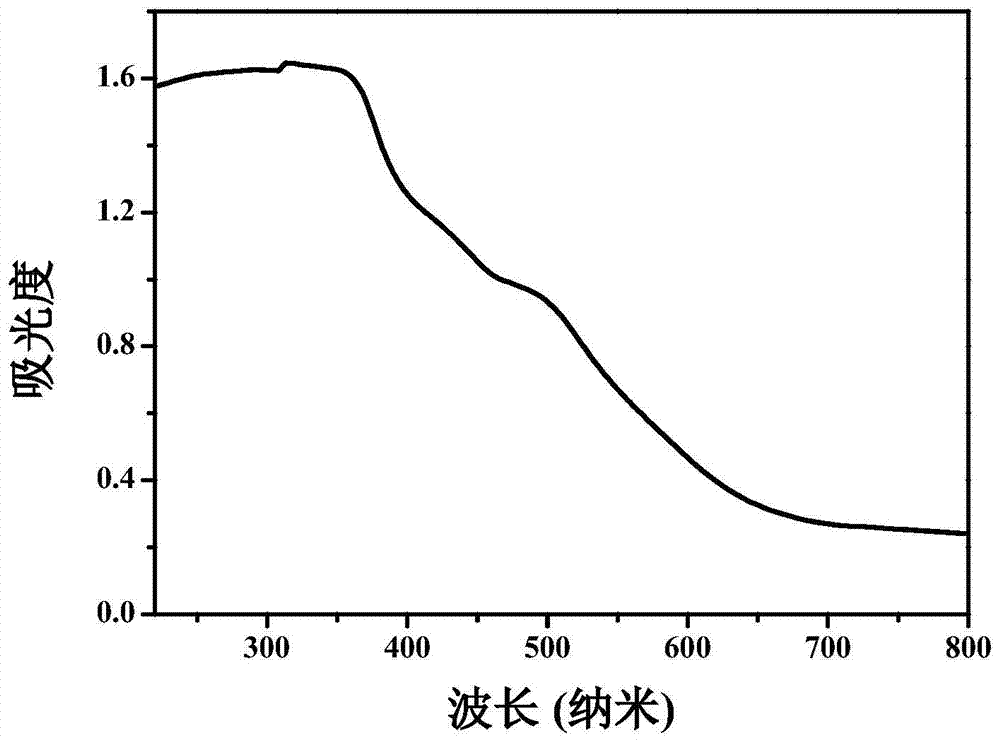

[0021] Weigh 1.3387g Zn(NO 3 ) 2 ·6H 2 O, 0.1759g In(NO 3 ) 3 ·5H 2 O and 0.4242g Fe(NO 3 ) 3 9H 2 O was dissolved in 30mL deionized water to make a solution, the concentration of the mixed metal salt solution was 0.2M; weigh 0.48g NaOH and 0.53gNa 2 CO 3 Dissolve in 50mL deionized water to make a mixed solution, the concentrations are [NaOH]=1.6[Zn 2+ ], [Na 2 CO 3 ]=2([In 3 + ]+[Fe 3+ ]). The mixed metal salt solution and the mixed alkali solution were respectively placed in two constant-pressure dropping funnels, and the water bath temperature was 35°C. While stirring, the solution was added dropwise into the four-necked bottle, and the dropping rate was adjusted to keep the pH at 9.5-10. within range. Then it was crystallized at constant temperature in a water bath at 65°C for 24h. After the reaction, the reaction product was centrifuged with deionized water (3500r / min) and washed to neutrality, and the resulting slurry was dried overnight at 60°C, finely ...

Embodiment 2

[0024] Weigh 1.3387g Zn(NO 3 ) 2 ·6H 2 O, 0.2932g In(NO 3 ) 3 ·5H 2 O and 0.3030g Fe(NO 3 ) 3 9H 2 O was dissolved in 30mL deionized water to make a solution, the concentration of the mixed metal salt solution was 0.2M; weigh 0.48g NaOH and 0.53gNa 2CO 3 Dissolve in 50mL deionized water to make a mixed solution, the concentrations are [NaOH]=1.6[Zn 2+ ], [Na 2 CO 3 ]=2([In 3 + ]+[Fe 3+ ]). Prepared under the same conditions as in Example 1 [In 3+ ] / [M 3+ ]=0.5 / 0.5, [Zn 2+ ] / ([In 3+ ]+[M 3+ ]) = 3 / 1 Zn 3 In 0.5 Fe 0.5 - Ternary composite oxide materials. After 2 hours of irradiation under visible light, the catalytic degradation rate of methylene blue reached 88.5%, and the reaction rate constant was 17.9×10 -3 min -1 , is Zn 3 2.38 times that of Fe-binary composite oxide material.

Embodiment 3

[0026] Weigh 1.3387g Zn(NO 3 ) 2 ·6H 2 O, 0.4105g In(NO 3 ) 3 ·5H 2 O and 0.1818g Fe(NO 3 ) 3 9H 2 O was dissolved in 30mL deionized water to make a solution, and the concentration of the mixed metal salt solution was 0.2M; weigh 0.48gNaOH and 0.53gNaOH 2 CO 3 Dissolve in 50mL deionized water to make a mixed solution, the concentrations are [NaOH]=1.6[Zn 2+ ], [Na 2 CO 3 ]=2([In 3 + ]+[Fe 3+ ]). Prepared under the same conditions as in Example 1 [In 3+ ] / [M 3+ ]=0.7 / 0.3, [Zn 2+ ] / ([In 3+ ]+[M 3+ ]) = 3 / 1 Zn 3 In 0.7 Fe 0.3 - Ternary composite oxide materials. After 2 hours of irradiation under visible light, the catalytic degradation rate of methylene blue reached 82.3%, and the reaction rate constant was 14.3×10 -3 min -1 , is Zn 3 1.90 times that of Fe-binary composite oxide material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com