High strength steel plate stamping part thermal forming production automation line

A high-strength steel plate and stamping technology, applied in the field of thermoforming, can solve the problems of high cost, large equipment volume, small application range, etc., and achieve the effect of low cost, good effect and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

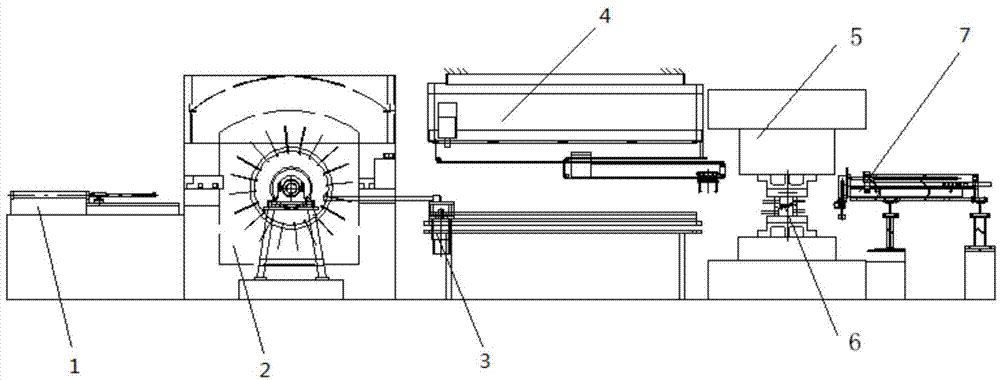

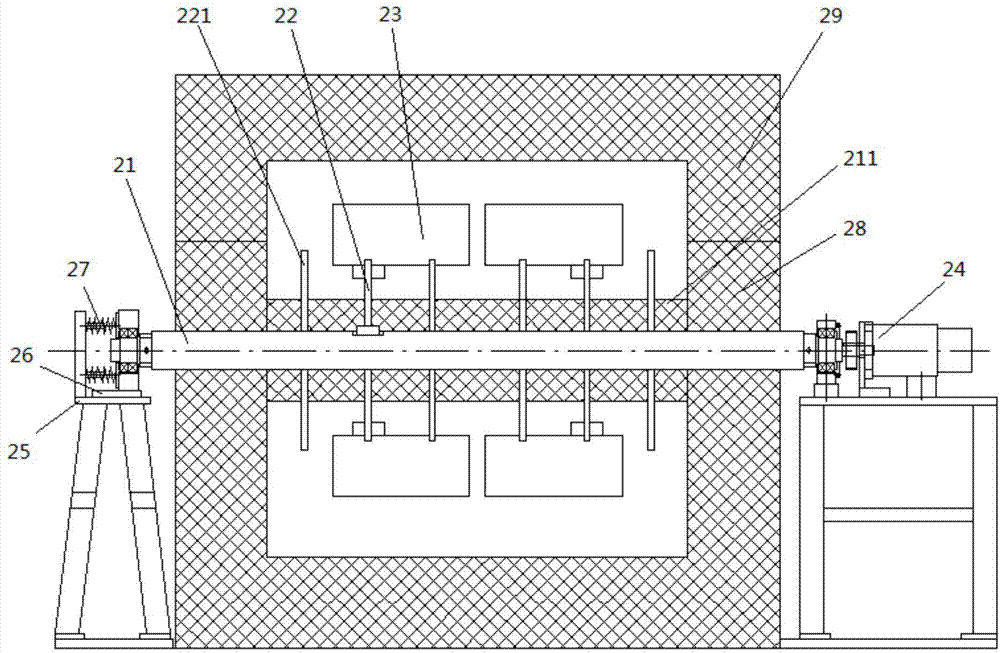

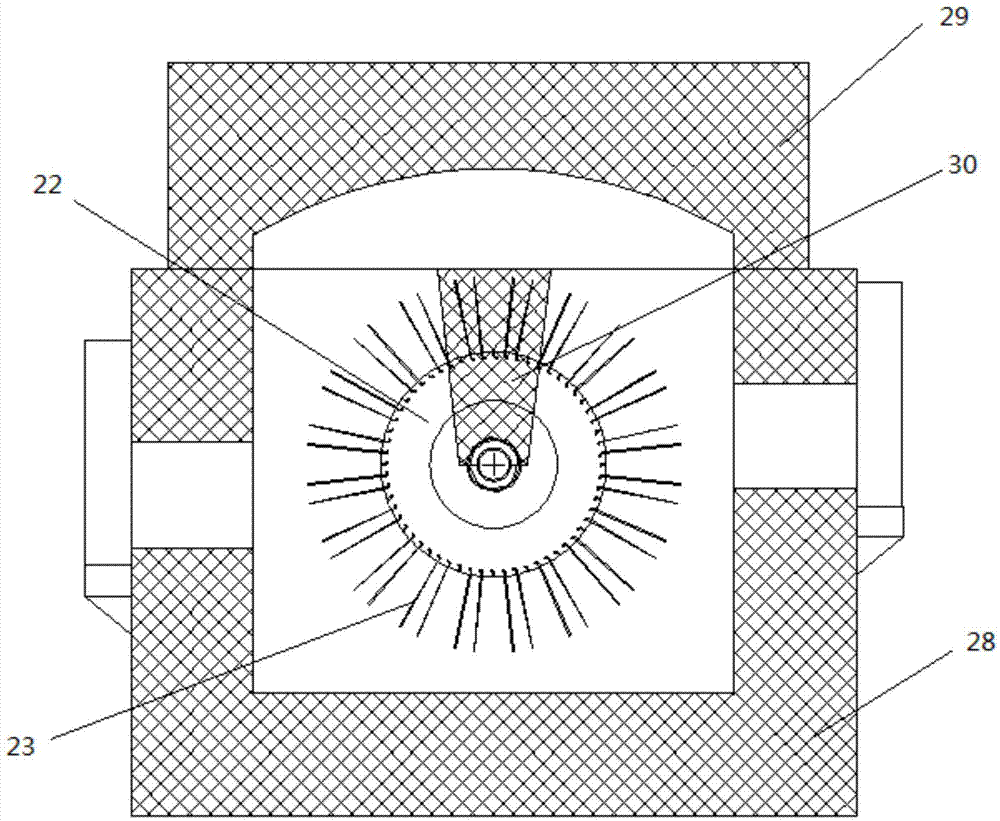

[0045] An automatic production line for hot forming of high-strength steel stamping parts, such as figure 1As shown, it includes a feeding device 1, a quick-change blade wheel shaft heating furnace 2, a lower conveying device 3, an upper conveying device 4, a high-speed press 5 and a pick-up device 7 arranged in sequence. The high-speed press 5 is equipped with Water-cooled mold 6; the feeding device 1 sends the workpiece into the quick-change blade hub-type heating furnace 2 for high-temperature heating, the lower conveyor device 3 takes the heated workpiece out of the quick-change blade hub-type heating furnace 2, and the upper conveyor device 4 Arranged above the lower conveyor device 3, it grabs the workpieces taken out by the lower conveyor device 3 and transfers them to the high-speed press 5 for molding. machine for delivery.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com