Automatic cutter disassembling device

A knife device, automatic technology, applied in the direction of positioning device, clamping, support, etc., can solve the problems of inconvenient operation, fast tool wear, and dimensional deviation of workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in conjunction with examples, but the embodiments of the present invention are not limited thereto.

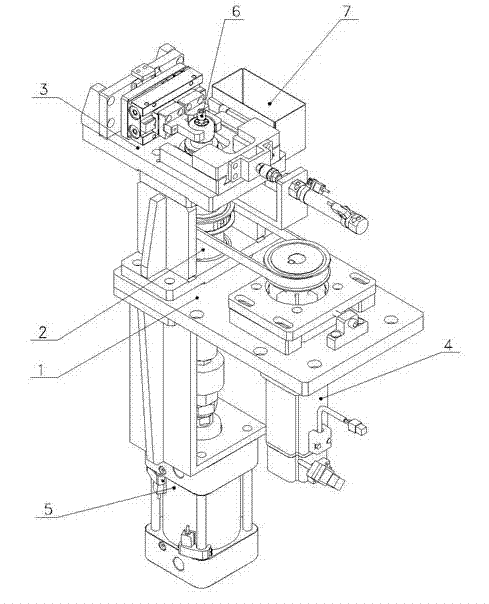

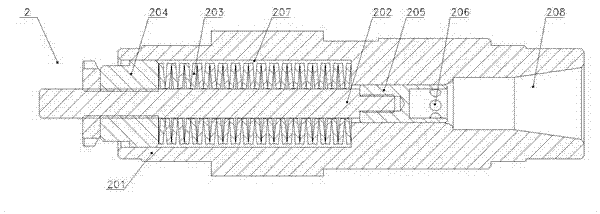

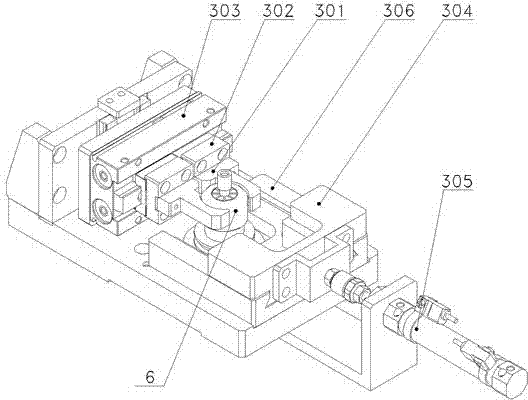

[0015] see Figures 1~5 , the present invention provides an automatic tool removal device, comprising: a fixed base plate 1, a spindle mechanism 2 perpendicular to the fixed base plate 1 and one end bearing connected to the fixed base plate 1, a tool handle clamping mechanism 3 located above the spindle mechanism 2, a control The transmission mechanism 4 for the rotation of the main shaft mechanism 2, and the jacking cylinder mechanism 5 located below the main shaft mechanism 2; The disc spring compression nut 204 threaded at the bottom, the pull claw 205 threaded with the top of the pull rod 202, the steel ball 206 positioned at the end of the pull claw 205 away from the pull rod; The connected jaw fixing block 302, the first cylinder 303 that is slidably connected with the jaw fixing block 302 and controls the opening a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com