Large-diameter high-temperature bolt dismounting tool

A technology of high-temperature bolts and disassembly tools, applied in the field of disassembly tools, can solve problems such as difficulty, large diameter of bolts, slippage of pipe wrenches, etc., and achieve the effect of saving time and labor in installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

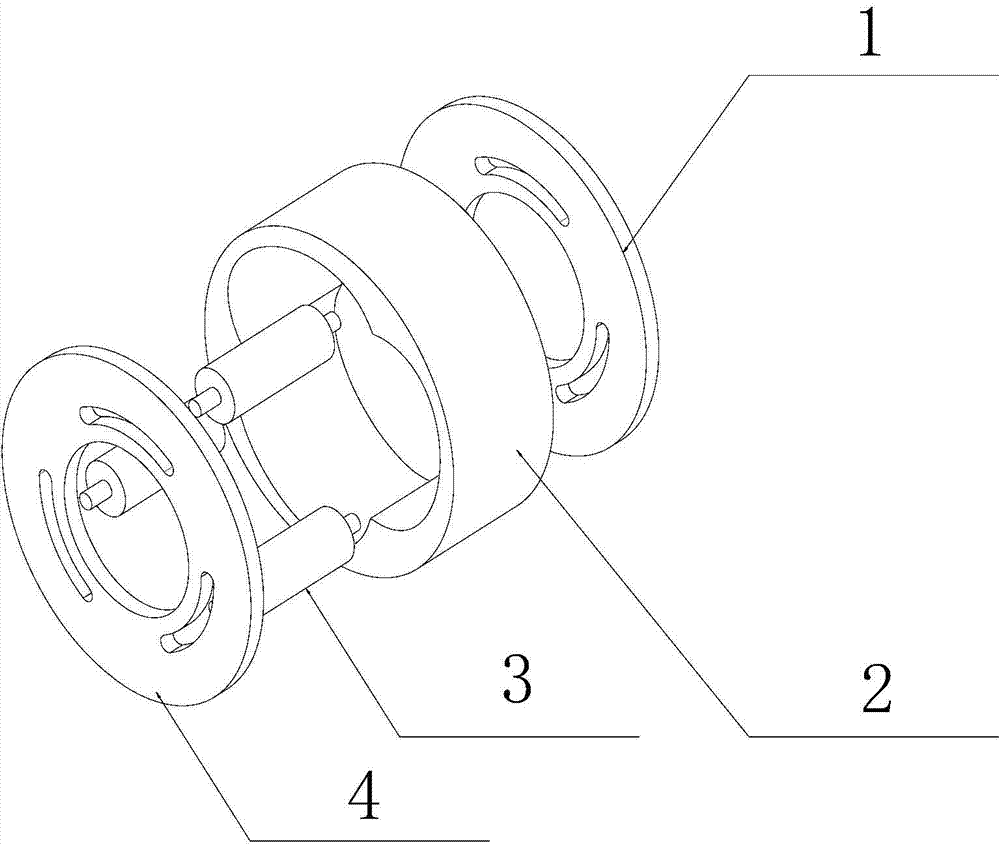

[0019] Such as figure 1 As shown, a large-diameter high-temperature bolt removal tool includes an upper cover plate 1, a lower cover plate 4, a roller 3 and a housing 2, and the upper cover plate 1 and the lower cover plate 4 are installed on both sides of the housing 2 respectively. side, the two ends of the roller 3 are respectively installed in the sliding grooves of the upper cover 1 and the lower cover 4, and the middle part of the roller 3 slides in the radial depth of the shell gradually becoming longer grooves .

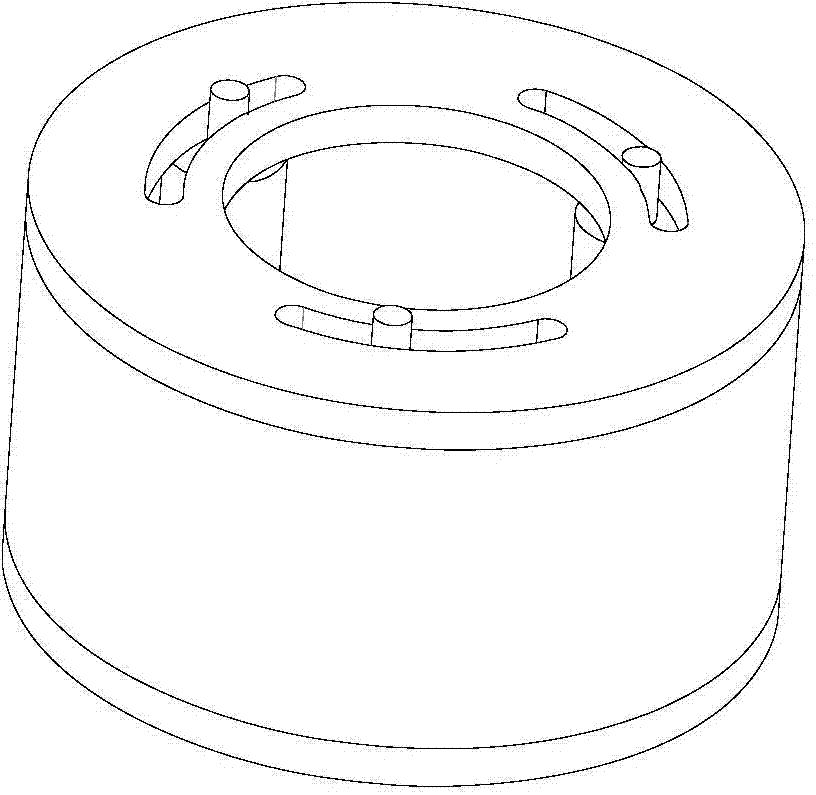

[0020] The center of the upper cover plate 1 and the lower cover plate 4 has a round hole, and the outer side of the round hole is evenly distributed with arc-shaped grooves for sliding the ends of the rollers. There are three rollers 3, and each roller has a convex body at both ends, and is inserted into the three arc-shaped grooves of the upper cover 1 and the lower cover 4 respectively. There are three grooves in the housing 2, which are slidably connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com