Grain bagging device

A bagging device and grain technology, applied in the field of machinery, can solve the problems of large fan size, many parts, long process, etc., and achieve the effect of improving production efficiency, fewer parts and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

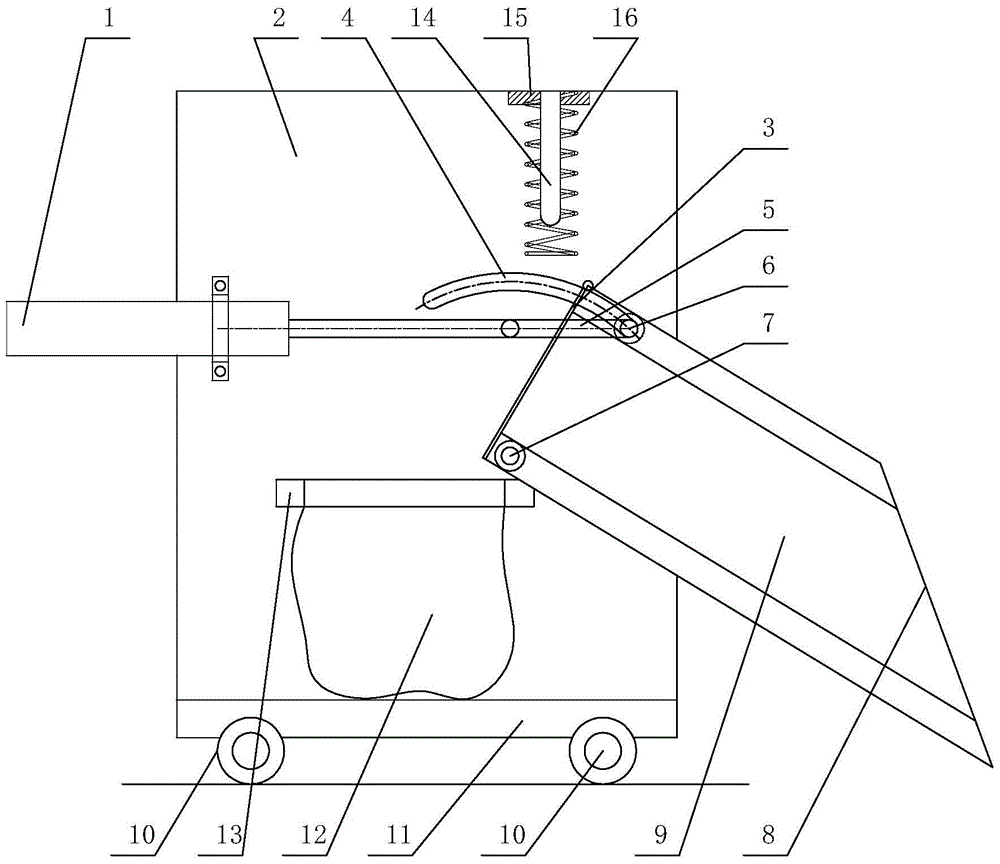

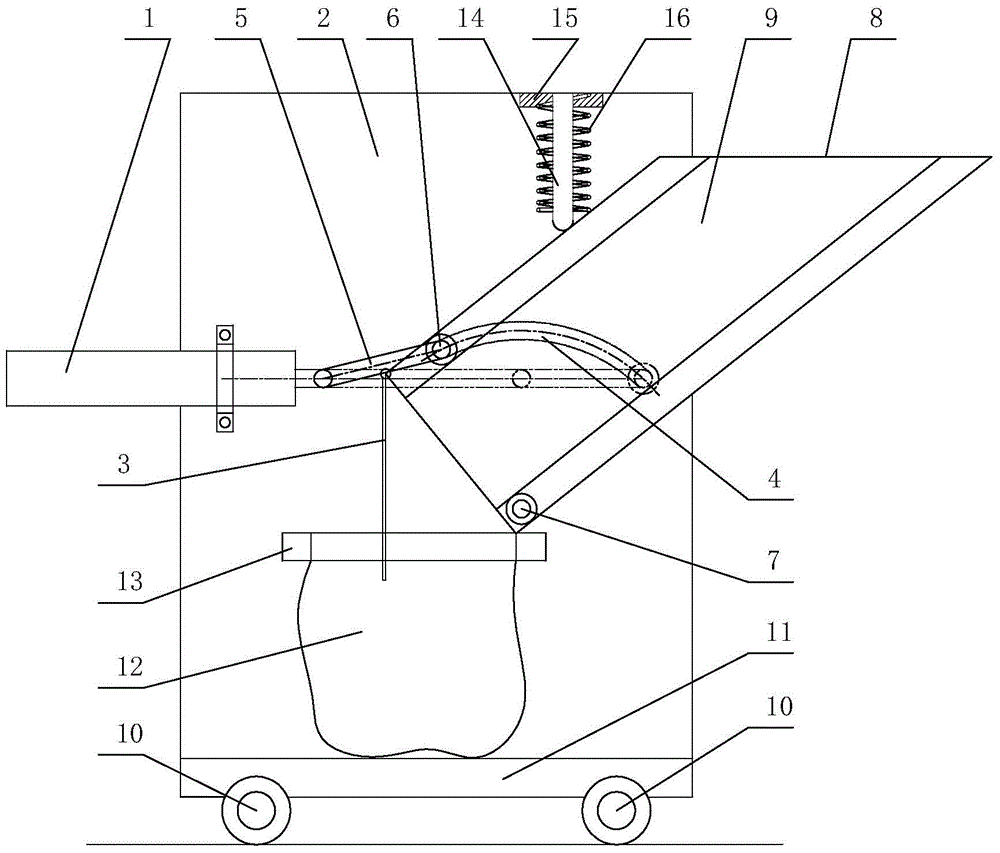

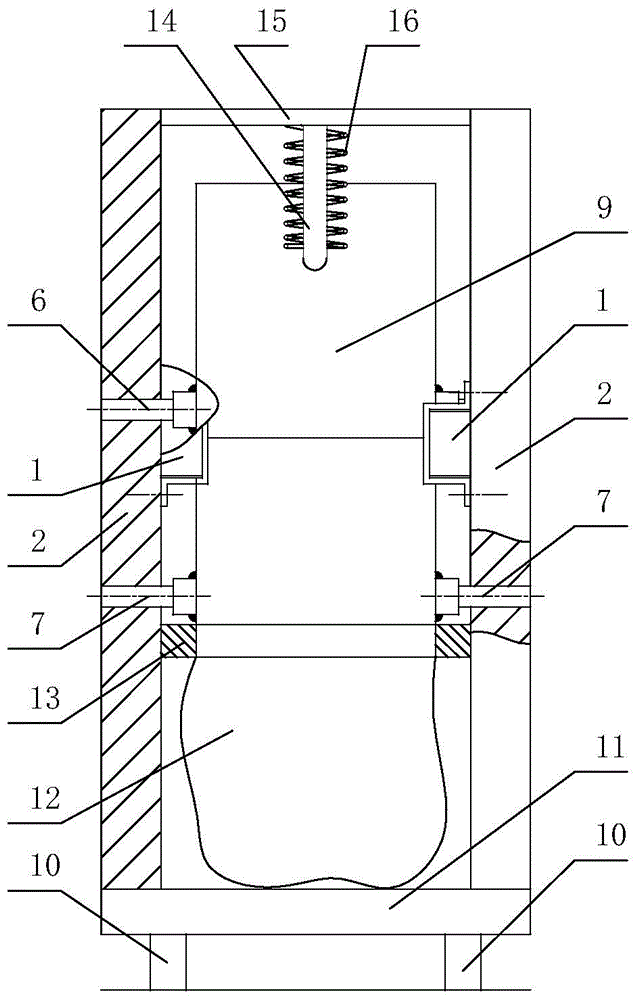

[0027] Depend on Figure 1 ~ Figure 3 As can be seen from the schematic structural diagram of the grain bagging device of the present invention, it includes a movable base 11, a frame plate 2, a bag fixing device 13 for socketing a grain bag 12, a hopper 9, a hopper driving device and a hopper buffer device. The frame board 2 is two pieces, and the lower end of each frame board 2 is fixedly connected to the edge of the movable base 11 . The bag fixing device 13 is connected between the two rack plates 2 and is located in the middle of the rack plates 2 in the vertical direction. The hopper 9 is rotatably connected to the two frame plates 2 , and the rotatable connection point is located above the edge of the bag fixing device 13 . The hopper driving device is composed of two groups of driving assemblies, each group of driving assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com