Novel scraper conveyor with bins

A scraper conveyor, a new type of technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of chain damage, unbalanced force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

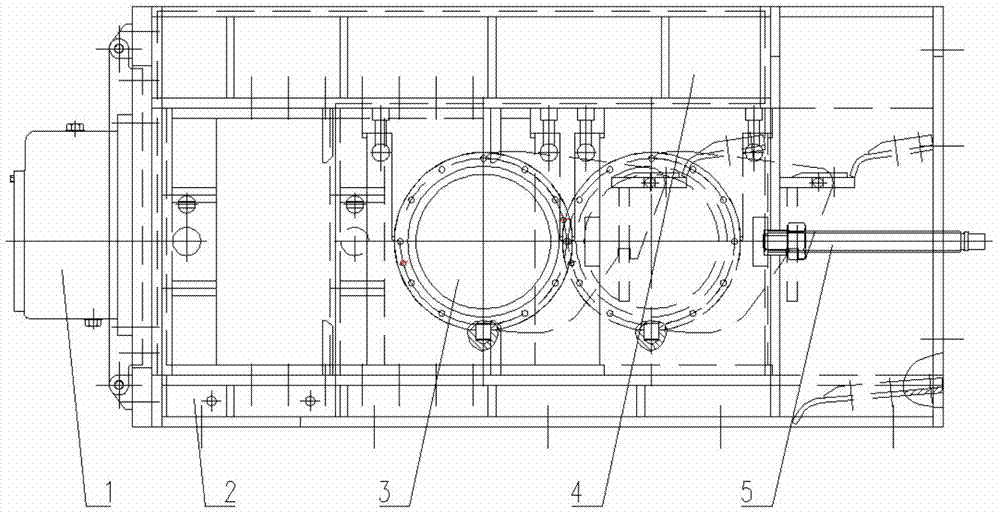

[0014] Such as figure 1 As shown, the present invention is a novel scraper conveyor for distributing warehouses, comprising a tail body 3 (i.e. parts such as a sprocket shaft group and two sprockets), and also includes a tail integral frame 2, on which the tail integral frame 2 A slideway is provided, and the tail body 3 is installed on the slideway, so that the tail body 3 can move along the slideway, specifically wherein a smooth plane is provided on the lower surface of the tail body 3 , so that it can cooperate with the slideway on the tail overall frame 2 to facilitate sliding. On the tail integral frame 2 of this tail body 3 one side, chain tightening device 1 is also installed, and on the tail integral frame 2 of this tail body 3 other sides, jacking wire 5 is then installed, thereby can in One side fixes the tail body 3. Wherein the chain tightening device 1 adopts a worm gear screw structure, and the top screw 5 adopts a screw rod.

[0015] Wherein the tail integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com