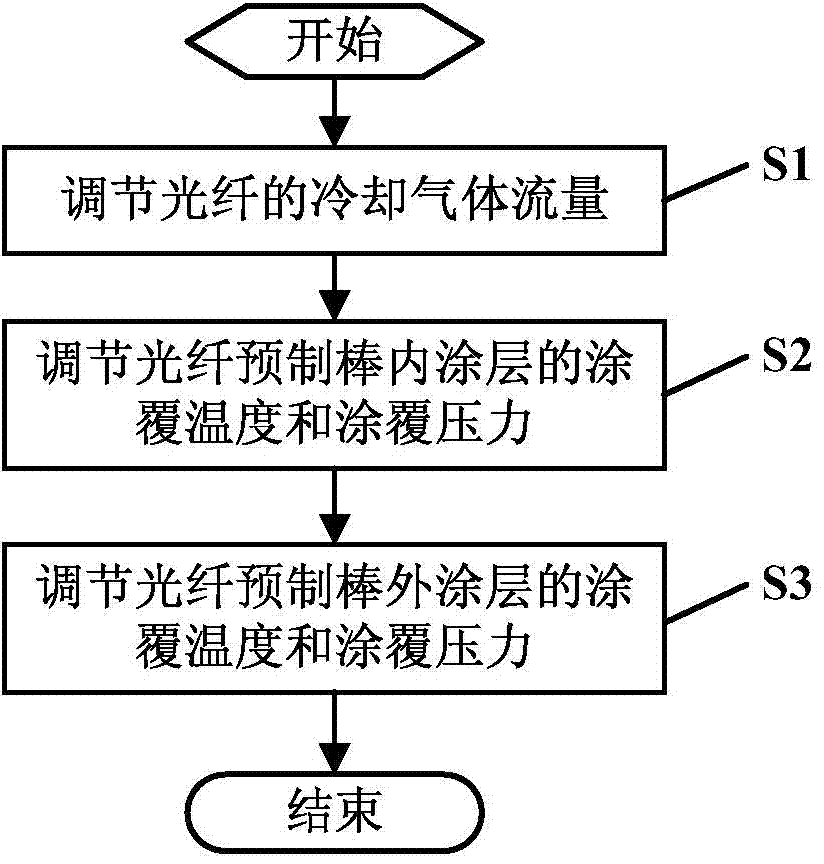

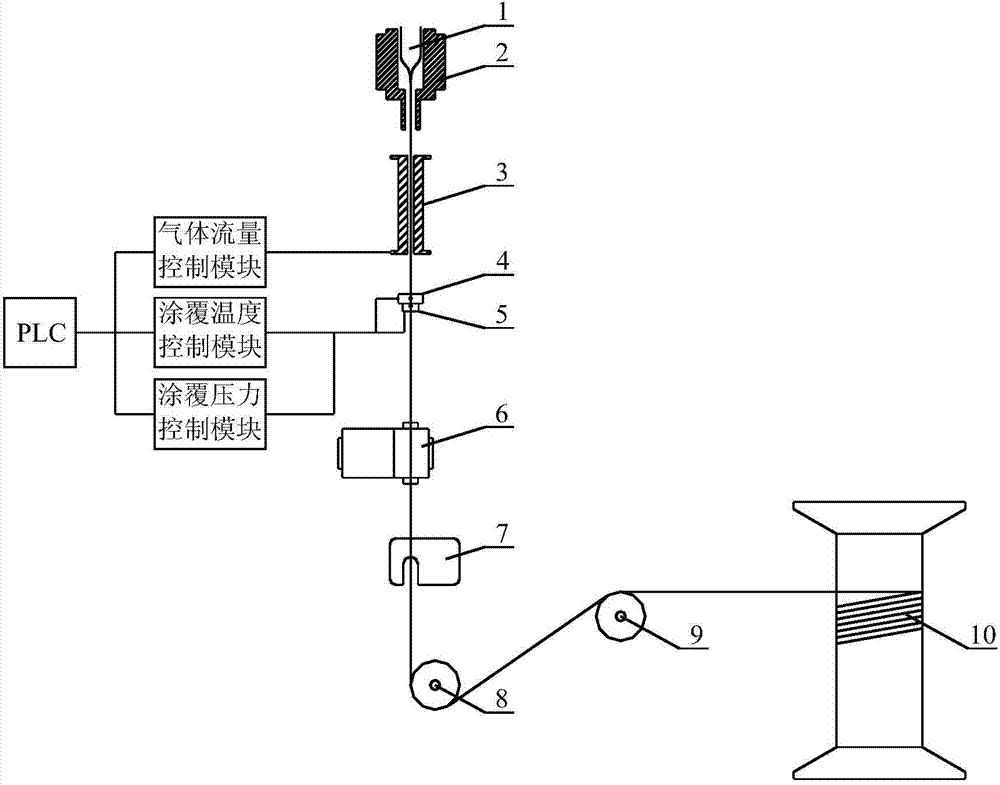

Method for automatically controlling fiber coating diameter, system thereof, and fiber wire drawing apparatus

A technology for coating and optical fiber, which is applied in the field of optical fiber drawing device and automatic control of optical fiber coating diameter, can solve the problems of single adjustment method, fluctuation of wire diameter, increase of material cost, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: The initial drawing speed of the traction wheel 9 is set to be 2100m / min, the initial flow rate of the cooling gas in the cooling pipe 3 is 10L / min; the initial coating temperature of the inner coating is 55°C, and the initial coating pressure is 7.5bar, the corresponding target inner coating diameter is 190um.

[0060] When the PLC detects that the speed of the traction wheel 9 decreases to 2050m / min with a step length of 15m / min: the PLC outputs the flow slope 0.008(L / min) / (m / min) to the gas flow control module, and the gas flow control module is based on the above The flow rate slope reduces the flow rate of the cooling gas in the cooling tube 3 to 9.6 L / min.

[0061] The PLC outputs the temperature adjustment slope of 0.02°C / (m / min) to the coating temperature control module, and the coating temperature control module reduces the coating temperature of the inner coating cup 4 to 54°C according to the above temperature adjustment slope.

[0062] The PLC ou...

Embodiment 2

[0064] Embodiment 2: The initial drawing speed of the traction wheel 9 is set to be 2100m / min, the initial flow rate of the cooling gas in the cooling pipe 3 is 10L / min; the initial coating temperature of the inner coating is 55°C, and the initial coating pressure is 7.5bar, the corresponding target inner coating diameter is 190um.

[0065] When the PLC detects that the speed of the traction wheel 9 increases to 2150m / min with a step length of 15m / min: the PLC outputs the flow slope 0.01(L / min) / (m / min) to the gas flow control module, and the gas flow control module is based on the above The flow rate slope is to increase the flow rate of the cooling gas in the cooling tube 3 to 10.5 L / min.

[0066] The PLC outputs the temperature adjustment slope of 0.025°C / (m / min) to the coating temperature control module, and the coating temperature control module increases the coating temperature of the inner coating cup 4 to 56.25°C according to the above temperature adjustment slope.

[...

Embodiment 3

[0069] Example 3: The initial drawing speed of the traction pulley 9 is set to 2100 m / min, the initial coating temperature of the outer coating is 60° C., the initial coating pressure is 7.0 bar, and the corresponding target outer coating diameter is 245 μm.

[0070] When the PLC detects that the speed of traction wheel 9 decreases to 2050m / min with a step size of 15m / min:

[0071] The PLC outputs the temperature adjustment slope of 0.02°C / (m / min) to the coating temperature control module, and the coating temperature control module reduces the coating temperature of the outer coating cup 5 to 59°C according to the above temperature adjustment slope.

[0072] The PLC outputs the pressure regulation slope of 0.002 bar / (m / min) to the coating pressure control module, and the coating temperature control module reduces the coating pressure of the outer coating cup 5 to 6.9 bar according to the above pressure regulation slope.

[0073] The coating diameter caliper 7 test shows that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com